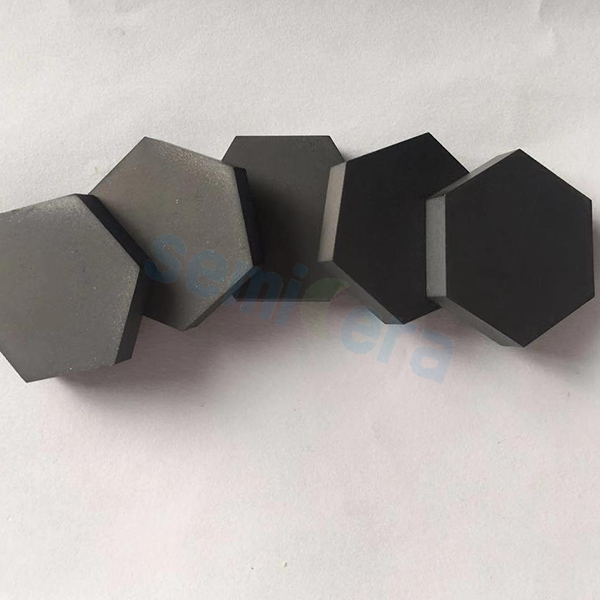

Silicon carbide (SiC) thepa e le 'ngoe ea kristale e na le lekhalo le leholo la lekhalo la sehlopha (~ Si makhetlo a 3), conductivity e phahameng ea mocheso (~Si 3.3 linako kapa GaAs makhetlo a 10), tekanyo e phahameng ea ho falla ha elektronike (~ Si 2.5 linako), ho senyeha ho matla ha motlakase tšimo (~ Si 10 linako kapa GaAs 5 linako) le litšobotsi tse ling tse hlaheletseng.

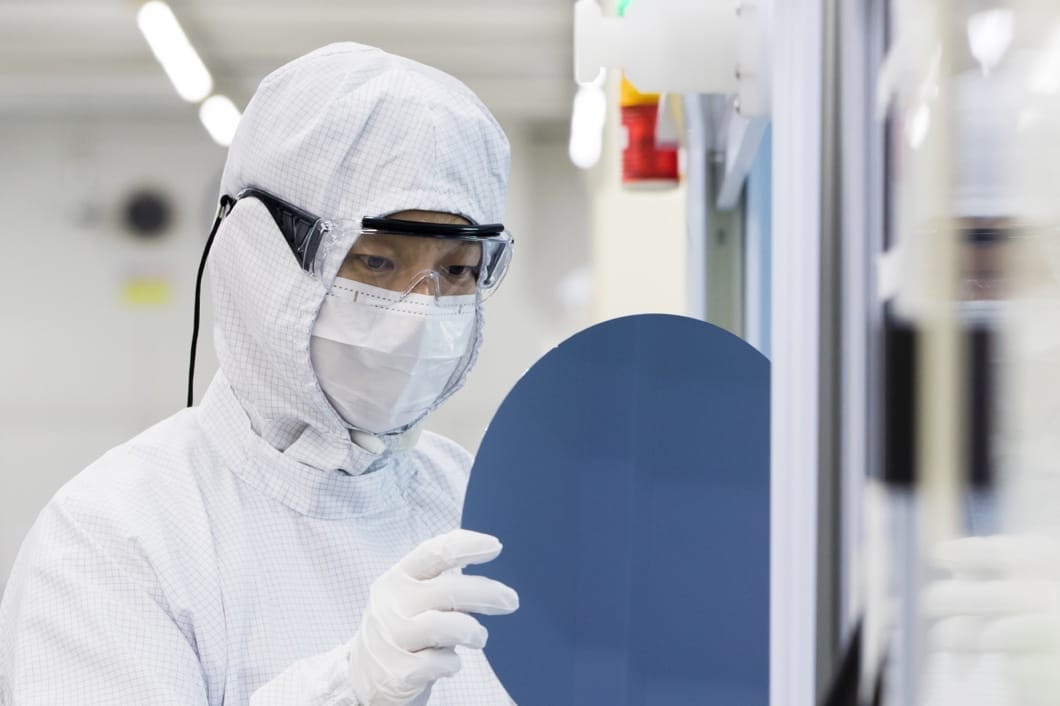

Matla a Semicera a ka fana ka bareki ba boleng bo phahameng ba Conductive (Conductive), Semi-insulating (Semi-insulating), HPSI (High Purity semi-insulating) silicon carbide substrate; Ho phaella moo, re ka fana ka bareki ba nang le homogeneous le heterogeneous silicon carbide epitaxial sheets; Re ka boela ra iketsetsa leqephe la epitaxial ho latela litlhoko tse khethehileng tsa bareki, 'me ha ho na palo e fokolang ea taelo.

| Lintho | Tlhahiso | Patlisiso | Dummy |

| Crystal Parameters | |||

| Polytype | 4H | ||

| Phoso ea sebopeho sa bokaholimo | <11-20>4±0.15° | ||

| Litekanyetso tsa Motlakase | |||

| Dopant | n-mofuta oa Nitrojene | ||

| Ho hanyetsa | 0.015-0.025ohm · cm | ||

| Mechanical Parameters | |||

| Diameter | 99.5 - 100 limilimithara | ||

| Botenya | 350±25 μm | ||

| Boemo ba mantlha bo bataletseng | [1-100]±5° | ||

| Bolelele ba pele bo bataletseng | 32.5±1.5mm | ||

| Boemo ba bobeli bo bataletseng | 90 ° CW ho tloha foleteng ea mantlha ± 5 °. silicon e shebile holimo | ||

| Bolelele ba bobeli bo bataletseng | 18±1.5mm | ||

| TTV | ≤5 μm | ≤10 μm | ≤20 μm |

| LTV | ≤2 μm(5mm*5mm) | ≤5 μm(5mm*5mm) | NA |

| Inamela | -15μm ~ 15μm | -35μm ~ 35μm | -45μm ~ 45μm |

| Warp | ≤20 μm | ≤45 μm | ≤50 μm |

| Front(Si-face) roughness(AFM) | Ra≤0.2nm (5μm*5μm) | ||

| Sebopeho | |||

| Boima ba micropipe | ≤1 e/cm2 | ≤5 ea/cm2 | ≤10 ea/cm2 |

| Litšila tsa tšepe | ≤5E10atoms/cm2 | NA | |

| BPD | ≤1500 ea/cm2 | ≤3000 ea/cm2 | NA |

| TSD | ≤500 ea/cm2 | ≤1000 ea/cm2 | NA |

| Boleng ba Pele | |||

| Pele | Si | ||

| Qetello ea bokaholimo | Si-face CMP | ||

| Likaroloana | ≤60ea/wafer (boholo ≥0.3μm) | NA | |

| Mengwapo | ≤2ea/mm. Bolelele ba kakaretso ≤Diameter | Bolelele bo akaretsang≤2*Diameter | NA |

| Lekhapetla la lamunu/makoti/matheba/maphatso/mapetso/tshilafatso | Ha ho letho | NA | |

| Li-edge chips/indents/fracture/hex plates | Ha ho letho | NA | |

| Libaka tsa polytype | Ha ho letho | Kakaretso≤20% | Kakaretso≤30% |

| Ho tšoaea ka laser ka pele | Ha ho letho | ||

| Boleng ba Morao | |||

| Qetello ea morao | C-sefahleho sa CMP | ||

| Mengwapo | ≤5ea/mm, bolelele bo akaretsang≤2* bophara | NA | |

| Litšitiso tse ka morao (li-chips / indents) | Ha ho letho | ||

| Bokhopo ba mokokotlo | Ra≤0.2nm (5μm*5μm) | ||

| Ho tšoaea ka morao laser | 1 mm (ho tloha pheletsong e ka holimo) | ||

| Qetello | |||

| Qetello | Chamfer | ||

| Sephutheloana | |||

| Sephutheloana | Mokotla o ka hare o tlatsitsoe ka naetrojene 'me mokotla o ka ntle oa tlosoa. Multi-wafer cassette, epi-ready. | ||

| *Lintlha: "NA" e bolela hore ha ho na kopo Lintho tse sa boleloang li ka lebisa ho SEMI-STD. | |||

-

Lisebelisoa tsa Refractory tse Rekoang ka ho Fetisisa-Mocheso o Phahameng...

-

Semiconductor ea boleng bo botle ba Wafer Sucker Alumina ...

-

Theko e kholo ea Sehlahisoa se Secha sa Ceramic Beam Silico...

-

China Sehlahisoa se Secha sa Silicon Carbide Radiation Sis...

-

2019 boleng bo phahameng ba Sic Oxide Silicon Carbide Cer...

-

OEM/ODM Factory Silicon Carbide/Sic Mechanical ...