Silicon carbide (SiC) epitaxy

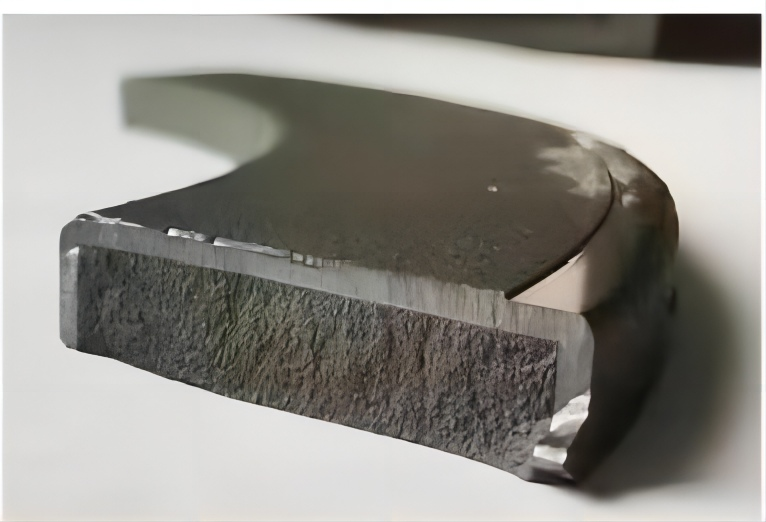

The epitaxial tray, e nang le SiC substrate bakeng sa ho hōlisa SiC epitaxial slice, e behiloeng ka kamoreng ea karabelo 'me e kopana ka ho toba le sephaphatha.

Karolo e ka holimo ea halofo ea khoeli ke sesebelisoa sa lisebelisoa tse ling tsa kamore ea karabelo ea lisebelisoa tsa Sic epitaxy, ha karolo e ka tlase ea khoeli e hokahane le tube ea quartz, e hlahisang khase ho khanna setsi sa susceptor ho potoloha. li khona ho laola mocheso 'me li kenngoa ka kamoreng ea ho arabela ntle le ho kopana ka ho toba le sephaphatha.

Ke epitaxy

Terei, e ts'oereng karoloana ea Si bakeng sa ho holisa selae sa Si epitaxial, se behiloe ka kamoreng ea karabelo 'me se hokahane ka kotloloho le sephaphatha.

Lesale la preheating le fumaneha ka ntle ho lesale la Si epitaxial substrate tray mme le sebelisetsoa ho lekanya le ho futhumatsa. E kenngoa ka kamoreng ea karabelo 'me ha e kopane ka ho toba le sephaphatha.

Epitaxial susceptor, e ts'oereng karoloana ea Si bakeng sa ho holisa selae sa Si epitaxial, se behiloe ka phapusing ea karabelo mme se ikopanya ka kotloloho le sephaphatha.

Epitaxial barrel ke likarolo tse ka sehloohong tse sebelisoang mekhoeng e sa tšoaneng ea tlhahiso ea semiconductor, e sebelisoang ka kakaretso lisebelisoa tsa MOCVD, tse nang le botsitso bo botle ba mocheso, lik'hemik'hale tse hanyetsanang le ho apara, tse loketseng haholo bakeng sa ho sebelisoa ha mocheso o phahameng. E kopana le liphaephe.

| Thepa ea 'mele ea Recrystallized Silicon Carbide | |

| Thepa | Boleng bo Tlwaelehileng |

| Mocheso oa ho sebetsa (°C) | 1600°C (ka oksijene), 1700°C (ho fokotsa tikoloho) |

| Likahare tsa SiC | 99.96% |

| Free Si content | <0.1% |

| Boima ba bongata | 2.60-2.70 g/cm3 |

| porosity e bonahalang | <16% |

| Matla a ho hatella | > 600 MPa |

| Matla a ho kobeha a batang | 80-90 MPa (20°C) |

| Matla a ho kobeha a chesang | 90-100 MPa (1400°C) |

| Katoloso ea mocheso @1500°C | 4.70 10-6/°C |

| Thermal conductivity @1200°C | 23 W/m•K |

| Modulase oa elastic | 240 GPA |

| Ho hanyetsa mocheso oa mocheso | E ntle haholo |

| Thepa ea 'mele ea Sintered Silicon Carbide | |

| Thepa | Boleng bo Tlwaelehileng |

| Sebopeho sa Lik'hemik'hale | SiC>95%, Si<5% |

| Boima ba Bongata | >3.07 g/cm³ |

| porosity e bonahalang | <0.1% |

| Modulus ea ho phatloha ho 20 ℃ | 270 MPa |

| Modulus ea ho phatloha ho 1200 ℃ | 290 MPa |

| Ho thatafala ho 20 ℃ | 2400 Kg/mm² |

| Ho robeha ho thata ho 20% | 3.3 MPa · m1/2 |

| Thermal Conductivity ho 1200 ℃ | 45 w/m .K |

| Katoloso ea mocheso ho 20-1200 ℃ | 4.5 1 ×10 -6/℃ |

| Max.mocheso o sebetsang | 1400 ℃ |

| Ho hanyetsa mocheso oa mocheso ho 1200 ℃ | E ntle |

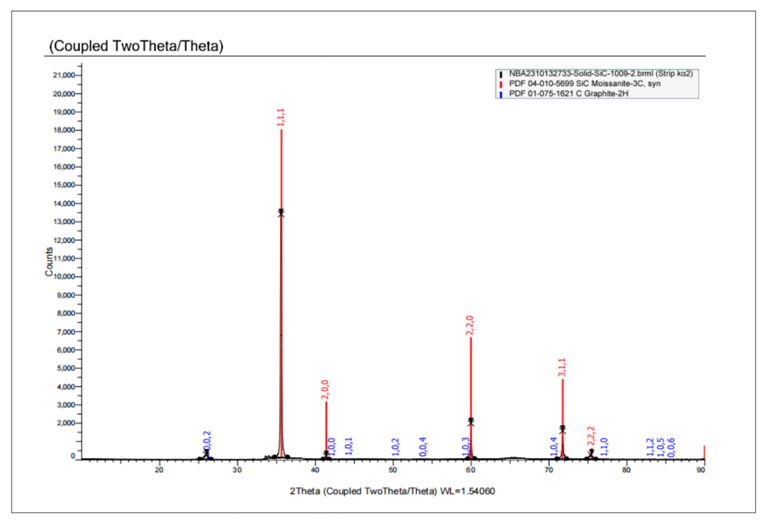

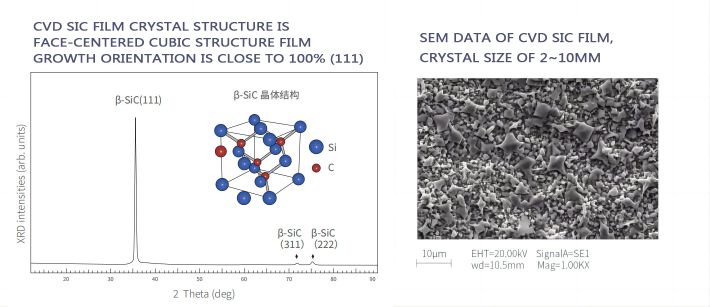

| Lintho tsa motheo tsa 'mele tsa lifilimi tsa CVD SiC | |

| Thepa | Boleng bo Tlwaelehileng |

| Sebopeho sa Crystal | FCC β phase polycrystalline, haholo-holo (111) e sekametseng |

| Botenya | 3.21 g/cm³ |

| Boima ba 2500 | (500g mojaro) |

| Boholo ba lijo-thollo | 2 ~ 10μm |

| Bohloeki ba Lik'hemik'hale | 99.99995% |

| Matla a Mocheso | 640 J·kg-1·K-1 |

| Sublimation Mocheso | 2700 ℃ |

| Flexural Matla | 415 MPa RT 4-ntlha |

| Modulus ea Bacha | 430 Gpa 4pt kobeha, 1300 ℃ |

| Thermal Conductivity | 300Wm-1·K-1 |

| Katoloso ea Thermal(CTE) | 4.5×10-6 K -1 |

Lintlha tse ka sehloohong

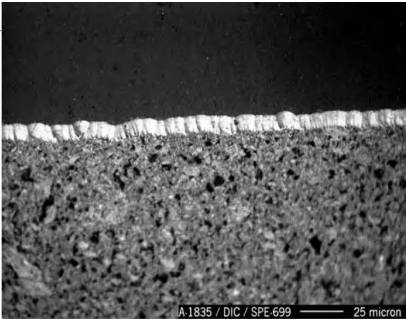

Bokaholimo bo teteaneng ebile ha bo na masoba.

Bohloeki bo phahameng, litaba tse sa hloekang ka ho feletseng <20ppm, moea o motle.

Ho hanyetsa mocheso o phahameng, matla a eketseha ka mocheso o ntseng o eketseha oa tšebeliso, o fihla boleng bo phahameng ka ho fetisisa ho 2750 ℃, sublimation ho 3600 ℃.

Modulus e tlase ea elastic, conductivity e phahameng ea mocheso, coefficient e tlase ea katoloso ea mocheso, le khanyetso e ntle ea mocheso oa mocheso.

Botsitso bo botle ba lik'hemik'hale, bo hanyetsanang le asiti, alkali, letsoai le li-reagents tsa manyolo, 'me ha bo na phello holim'a tšepe e qhibilihisitsoeng, slag le mecha e meng e senyang. Ha e na oxidize haholo sepakapakeng se ka tlase ho 400 C, mme sekhahla sa oxidation se eketseha haholo ho 800 ℃.

Ntle le ho ntša khase efe kapa efe mochesong o phahameng, e ka boloka vacuum ea 10-7mmHg ho pota 1800°C.

Sesebelisoa sa sehlahisoa

Melting crucible bakeng sa mouoane indastering ea semiconductor.

Heke ea tube ea elektronike e matla.

Brush e hokahaneng le motlakase oa motlakase.

Graphite monochromator bakeng sa X-ray le neutron.

Libopeho tse fapaneng tsa graphite substrates le atomic absorption tube coating.

Pyrolytic carbon coating effect ka tlas'a microscope ea 500X, e nang le bokaholimo bo tiileng le bo tiisitsoeng.

Ho roala ha TaC ke thepa e hanyetsanang le mocheso o phahameng oa moloko o mocha, e nang le botsitso bo betere ba mocheso o phahameng ho feta SiC. E le seaparo se thibelang kutu, sekontiri se khahlanong le oxidation le seaparo se thibelang ho roala, se ka sebelisoa tikolohong e ka holimo ho 2000C, se sebelisoang haholo libakeng tse chesang tsa mocheso oa mocheso o phahameng oa mocheso, moloko oa boraro oa semiconductor e le 'ngoe ea kholo ea kristale masimo.

| Thepa ea 'mele ea ho roala ha TaC | |

| Botenya | 14.3 (g/cm3) |

| Essivity e khethehileng | 0.3 |

| Coefficient ea ho eketsa mocheso | 6.3 10/K |

| Ho thatafala (HK) | 2000 HK |

| Khanyetso | 1x10-5 Ohm * cm |

| Ho tsitsa ha mocheso | <2500℃ |

| Boholo ba graphite bo fetoha | -10 ~ 20um |

| Botenya ba ho roala | ≥220um boleng bo tloaelehileng (35um±10um) |

Likarolo tse tiileng tsa CVD SILICON CARBIDE li amoheloa e le khetho ea mantlha bakeng sa mehele ea RTP/EPI le metheo le likarolo tsa plasma etch cavity tse sebetsang ka mocheso o phahameng o hlokahalang oa ho sebetsa (> 1500 ° C), litlhoko tsa bohloeki li phahame haholo (> 99.9995%) mme ts'ebetso e ntle haholo ha lik'hemik'hale tsa tol li phahame haholo. Lisebelisoa tsena ha li na mekhahlelo ea bobeli moeling oa lijo-thollo, kahoo likaroloana tsa theil li hlahisa likaroloana tse fokolang ho feta lisebelisoa tse ling. Ho phaella moo, likarolo tsena li ka hloekisoa ka ho sebelisa HF/HCI e chesang ka ho senyeha ho fokolang, ho fella ka likaroloana tse fokolang le bophelo bo bolelele ba tšebeletso.