Lintlha tse qaqileng tsa lesela le sa sebetseng la silicon carbide:

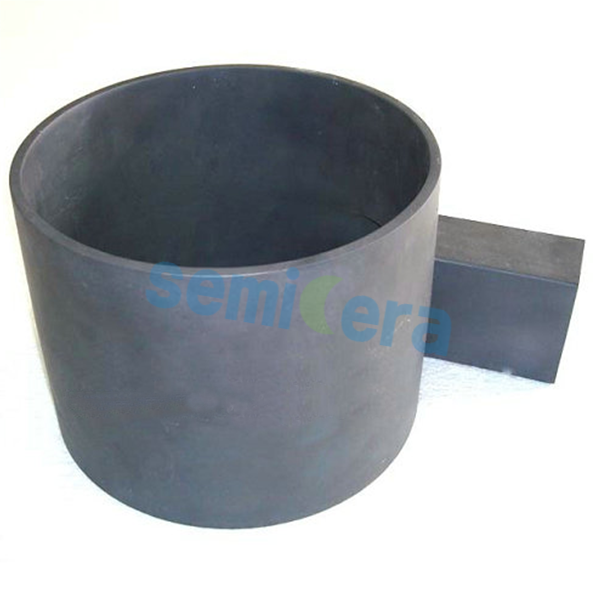

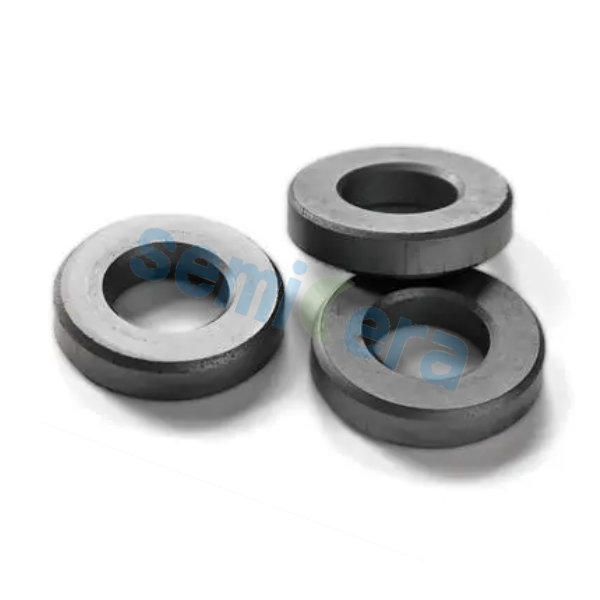

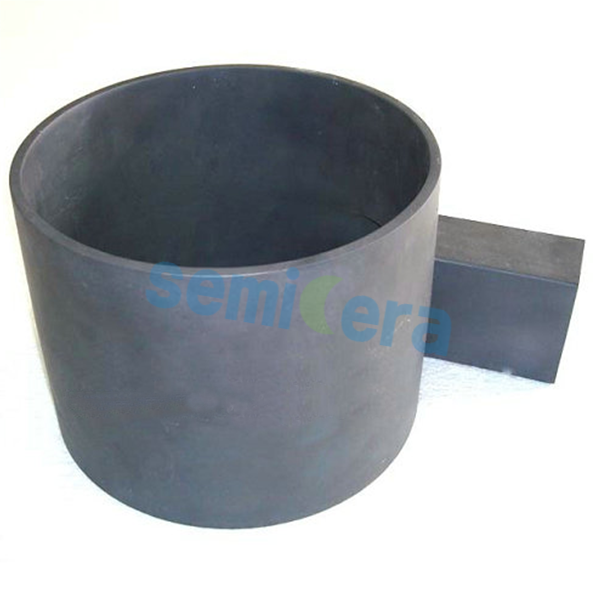

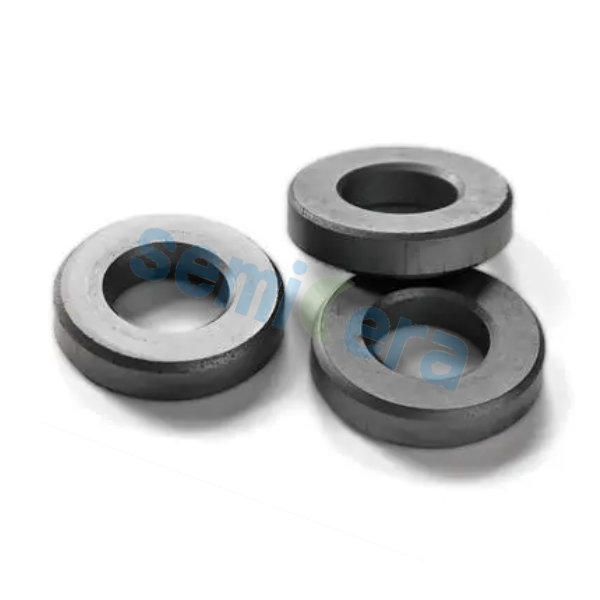

1, lebitso la sehlahisoa: silicon carbide wear-resistant lining, cyclone silicon carbide line, pipe e sa keneleng ea silicon carbide line, silicon carbide composite ceramic lening, composite ceramic pipe lening;

2, thepa ea lihlahisoa: karabelo-sintered silicon carbide ceramics;

3, mocheso oa ho sebetsa: ≤1380 ℃;

4, melemo ea sehlahisoa: ho hanyetsa mocheso le mocheso, acid, khanyetso ea alkali, boima bo phahameng, khanyetso ea oxidation, matla a phahameng, ha ho na slag, ha ho na ho phatloha, bophelo bo bolelele ba tšebeletso;

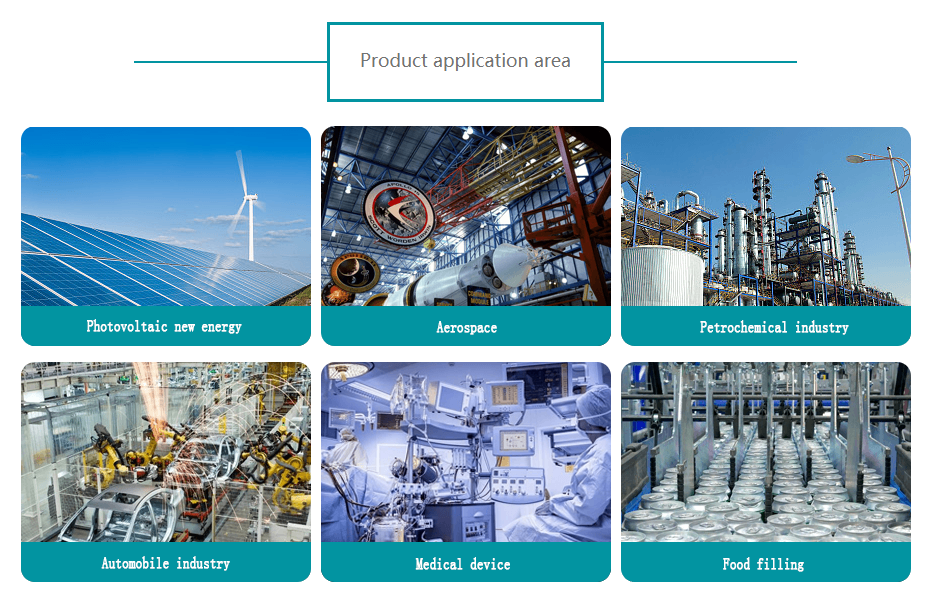

WeiTai Energy Technology Co., Ltd. ke mofani oa thepa ea ka sehloohong oa li-ceramics tse tsoetseng pele tsa semiconductor le moetsi feela Chaena ea ka fanang ka lisebelisoa tse phahameng tsa silicon carbide ceramic (haholo-holo Recrystallized SiC) le CVD SiC coating.Ho feta moo, k'hamphani ea rona e boetse e ikemiselitse ho etsa masimo a ceramic a kang alumina, aluminium nitride, zirconia, le silicon nitride, joalo-joalo.

Lihlahisoa tsa rona tsa mantlha li kenyelletsa: silicon carbide etching disc, silicon carbide boat tow, silicon carbide wafer boat (Photovoltaic&Semiconductor), silicon carbide furnace tube, silicon carbide cantilever paddle, silicon carbide chucks, silicon carbide beam, hammoho le CVD SiC coating le TaC. ho roala.Lihlahisoa tse sebelisoang haholo indastering ea semiconductor le photovoltaic, joalo ka lisebelisoa tsa kholo ea kristale, epitaxy, etching, ho paka, ho roala le libono tsa phallo, jj.

Khampani ea rona e na le lisebelisoa tse feletseng tsa tlhahiso tse kang ho bōpa, ho etsa sintering, ho sebetsa, lisebelisoa tsa ho roala, joalo-joalo, tse ka tlatsang lihokelo tsohle tse hlokahalang tsa tlhahiso ea lihlahisoa le ho ba le taolo e phahameng ea boleng ba sehlahisoa;Morero o nepahetseng oa tlhahiso o ka khethoa ho ea ka litlhoko tsa sehlahisoa, ho fella ka theko e tlaase le ho fa bareki lihlahisoa tse ngata tsa tlhōlisano;Re ka khona ho hlophisa tlhahiso ka mokhoa o bonolo le ka katleho ho latela litlhoko tsa ho fana ka taelo le ka kopanelo le litsamaiso tsa taolo ea odara ea inthaneteng, ho fa bareki nako e potlakileng le e netefalitsoeng ea ho fana ka nako.

Ka nako e ts'oanang, k'hamphani ea rona e itšetlehile ka lihlopha tsa litsebi tse kang litsi tsa theknoloji ea khoebo, liunivesithi tsa boemo ba pele, le litsi tsa lipatlisiso ho theha sehlopha sa boqapi le lipatlisiso tse nang le lingaka tse ngata, benghali le baenjiniere, ho rala motheo o tiileng bakeng sa nts'etsopele ea nako e telele. .

Amohela bareki ho tsoa lefats'eng lohle ho re etela le ho ba le lipuisano tsa tekheniki, Re tla sebetsa 'moho le uena ho nts'etsapele le ho theha menyetla e metle.

-

Moralo o Tummeng bakeng sa ho hanyetsa mocheso oa mocheso...

-

Theko ea Fektheri Bakeng sa Liindasteri tse Customized Black S...

-

Mocheso o phahameng le ho hanyetsa ho hanyetsa ho thata haholo ...

-

Feme ea China Hardness Refractory Ceramic F...

-

Moropa o silang oa boleng bo holimo oa silicon carbide

-

Theko e theoleloang boleng bo holimo Silicon Carbide...