Seketsoana sa SiC Wafer

Sekepe sa silicon carbide waferke sesebelisoa se jereng moroalo bakeng sa li-wafers, tse sebelisoang haholo ts'ebetsong ea phallo ea letsatsi le semiconductor. E na le litšoaneleho tse kang ho hanyetsa ho roala, ho hanyetsa kutu, ho hanyetsa mocheso o phahameng oa mocheso, ho hanyetsa libomo tsa plasma, matla a ho jara mocheso o phahameng, mocheso o phahameng oa mocheso, mocheso o phahameng oa mocheso, le tšebeliso ea nako e telele eo ho seng bonolo ho e khumama le ho e senya. Khamphani ea rona e sebelisa lisebelisoa tse phahameng tsa silicon carbide ho netefatsa bophelo ba ts'ebeletso le ho fana ka meralo e ikhethileng, ho kenyeletsoa. tse fapa-fapaneng tse tsepameng le tse rapamengseketsoana sa liphaephe.

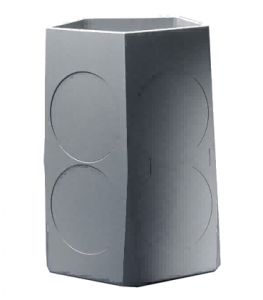

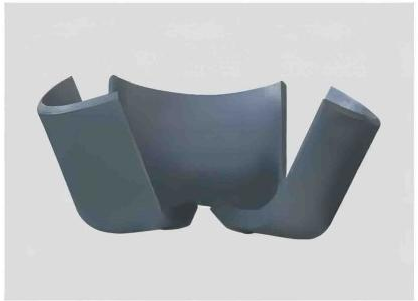

SiC Paddle

Thesilicon carbide cantilever paddlee sebelisoa haholo ho koahela (phatlalatso) ea liphaephe tsa silicon, tse bapalang karolo ea bohlokoa ho kenngoeng le ho tsamaiseng ha li-wafer tsa silicon mochesong o phahameng. Ke karolo ea bohlokoa easemiconductor sephaphathaloading system mme e na le litšobotsi tse latelang tse ka sehloohong:

1. Ha e holofatse libakeng tsa mocheso o phahameng 'me e na le matla a phahameng a ho laela holim'a li-wafers;

2. E hanyetsana le serame se feteletseng le mocheso o potlakileng, 'me e na le bophelo bo bolelele ba tšebeletso;

3. Coefficient ea ho atolosa mocheso e nyenyane, e atolosa haholo potoloho ea tlhokomelo le ho hloekisa, 'me e fokotsa haholo litšila.

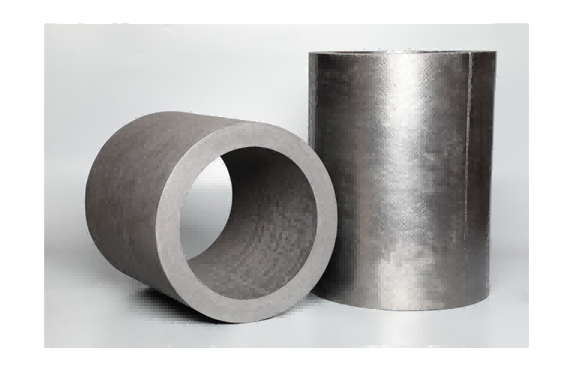

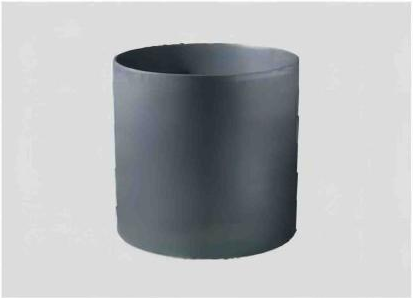

SiC Furnace Tube

Silicon carbide process tube, e entsoeng ka SiC e hloekileng ntle le litšila tsa tšepe, ha e silafatse sephaphatha, 'me e loketse mekhoa e kang semiconductor le photovoltaic diffusion, annealing le oxidation process.

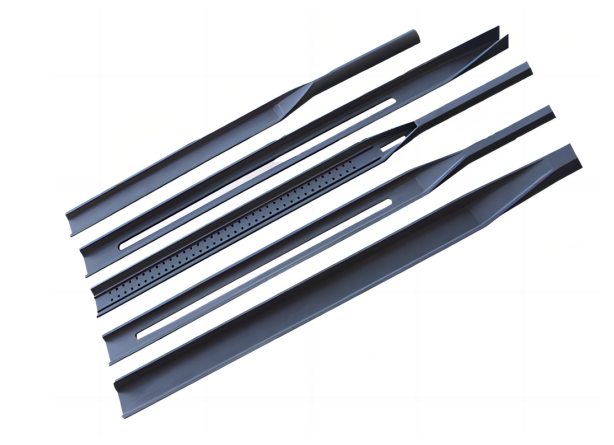

SiC Robot Arm

SiC letsoho la roboto, eo hape e tsejoang e le wafer transfer end effector, ke letsoho la robotiki le sebelisetsoang ho tsamaisa liphaphatha tsa semiconductor 'me le sebelisoa haholo indastering ea semiconductor, optoelectronic le solar energy. Ho sebelisa silicon carbide e hloekileng haholo, e nang le boima bo phahameng, khanyetso ea ho roala, ho hanyetsa litšisinyeho tsa lefatše, tšebeliso ea nako e telele ntle le deformation, bophelo bo bolelele ba tšebeletso, joalo-joalo, e ka fana ka litšebeletso tse ikhethileng.

Graphite bakeng sa kholo ea kristale

Graphite tse tharo-petal crucible

Tube ea tataiso ea graphite

Lesale la graphite

Thebe ea mocheso oa graphite

graphite electrode tube

graphite deflector

Sekhahla sa graphite

Mekhoa eohle e sebelisetsoang ho holisa li-semiconductor crvstals li sebetsa maemong a mocheso o phahameng le a senyang. Sebaka se chesang sa sebōpi sa khōlo ea kristale hangata se na le bohloeki bo phahameng bo thibelang mocheso le ho se bola. likarolo tsa graphite, tse kang li-heaters tsa graphite, crucibles, cylinders, deflector, chucks, tubes,rings, holders, nuts, joalo-joalo Sehlahisoa sa rona se felile se ka finyella molora o ka tlaase ho 5ppm.

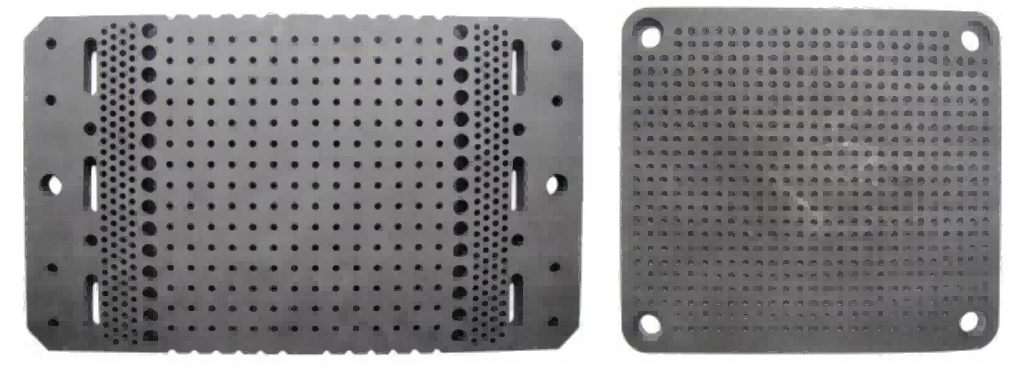

Graphite bakeng sa Semidonductor Epitaxy

Likarolo tsa MOCVD Graphite

Semiconductor Graphite Fixture

Ts'ebetso ea Epitaxial e bolela ho hola ha thepa e le 'ngoe ea kristale holim'a substrate e le' ngoe ea kristale e nang le tlhophiso e ts'oanang ea lattice joalo ka substrate. E hloka likarolo tse ngata tsa graphite tse hloekileng tse phahameng haholo le setsi sa graphite se nang le SIC. graphite e phahameng ea bohloeki e sebelisoang bakeng sa semiconductor epitaxy e na le mefuta e mengata ea lisebelisoa, e ka lumellanang le lisebelisoa tse sebelisoang ka ho fetisisa indastering, Ka nako e ts'oanang, e na le holimo haholo. bohloeki, ho roala junifomo, bophelo bo botle ba tšebeletso, le khanyetso e phahameng haholo ea lik'hemik'hale le botsitso ba mocheso.

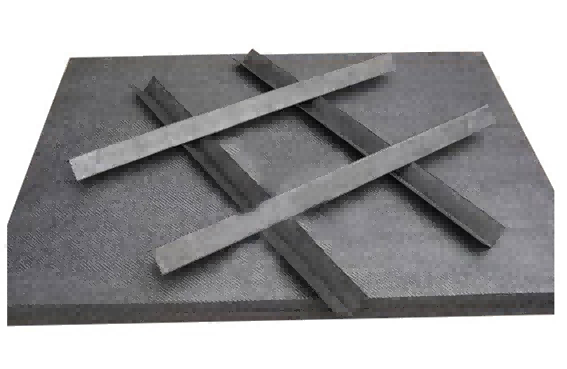

Insulation Material le tse ling

Lisebelisoa tsa ho kenya mocheso tse sebelisoang tlhahiso ea semiconductor ke graphite e thata, e ikutloang e le bonolo, graphite foil, lisebelisoa tsa carbon composite, joalo-joalo thepa ea rona e tala ke lisebelisoa tsa graphite tse tsoang linaheng tse ling, tse ka khaoloang ho ea ka litlhaloso tsa bareki, hape li ka rekisoa e le kaofela. Lintho tse nang le carbon composite hangata li sebelisoa e le sejari bakeng sa ts'ebetso ea tlhahiso ea lisele tsa letsatsi la monocrystal le polysilicon.