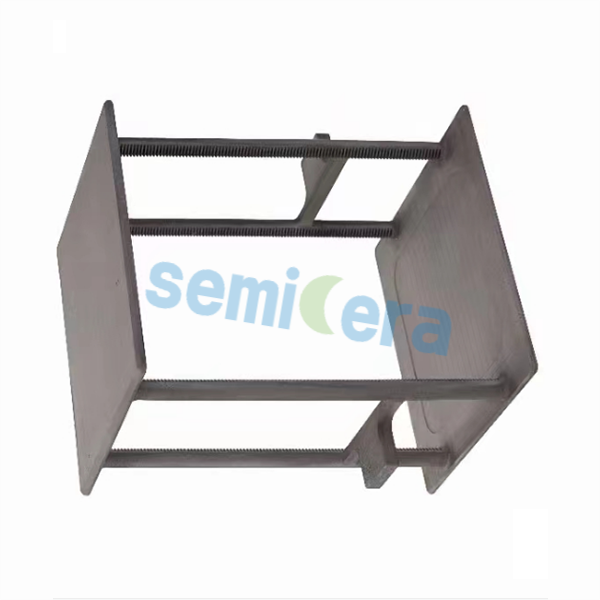

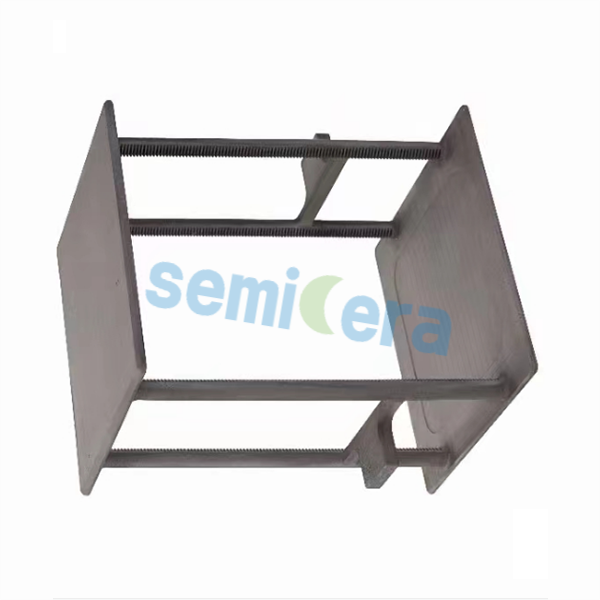

Tlhaloso

Moropa o silang oa silicon carbide o amohela mokhoa oa ho bopa oa isostatic, boima ba 3.09g/cm3, boholo ba φ950mm, Vickers hardness 2550HV.

Ts'ebeliso ea moqomo o silang oa Silicon Carbide ka har'a sesebelisoa sa ho futhumatsa

Silicon carbide ceramic grinding barrel e fetohile thepa e tala ea thepa ea cathode bakeng sa betri ea lithium ka lebaka la thepa ea eona ea bohlokoa ea conductive.SiC futhumatsang element ke sehlahisoa sa bohlokoa sa thepa ea SiC mme e na le tebello e pharalletseng ea mmaraka.

Molemo oa ho sila oa silicon carbide

(1) Matla a phahameng a mochini, joalo ka

Matla a phahameng a mechine a ka thibela ka katleho ho senyeha ha thepa, e leng ntho ea bohlokoa haholo.Silicon carbide e na le matla a phahameng a mochini ho feta corundum.Ka mohlala, matla a khatello ea silicon carbide ke 224MPa, athe corundum ke 75.7MPa feela.Matla a ho kobeha a silicon carbide ke 15.5MPa, 'me a corundum ke 8.72MPa.

(2) Boima bo phahameng le ho apara ho hanyetsa

Silicon carbide hardness e phahame haholo, ho ea ka boima ba li-notch tsa Mohs pakeng tsa 9.2 ~ 9.6, ea bobeli ka mor'a taemane le boron carbide, e phahameng ho feta corundum, kahoo ho sila le ho sisinyeha ho tloaelehileng har'a tse ntle ka ho fetisisa.Ha ho bapisoa le tšepe tšepe lintho tse bonahalang, ho ke ke ha feela phahameng thatafalloa, empa hape le ka boemo ba bao e seng lubricating ea khohlano coefficient ke e nyenyane, khohlano batlang e le nyenyane, holim'a roughness ke e nyenyane, apara ho hanyetsa e ntle.Ho phaella ho thepa ea ka ntle e na le tšusumetso e matla ea ho hanyetsa, ho ntlafatsa bokhoni ba ho jara holim'a metsi.

(3) Boima bo tlaase

Boima ba silicon carbide bo tlase ho feta ba tšepe, ka hona lisebelisoa li bobebe.

Khampani

Wei Tai Energy Technology Co., Ltd.(Miami Advanced Material Technology Co., Ltd) ke mofani oa thepa ea ka sehloohong oa lirafshoa tse tsoetseng pele tsa semiconductor le moetsi a le mong Chaena ea ka fanang ka ceramic carbide ceramic e hloekileng haholo (haholo-holo Recrystallized SiC) le Ho roala ha CVD SiC.Ho feta moo, k'hamphani ea rona e boetse e ikemiselitse ho etsa masimo a ceramic a kang alumina, aluminium nitride, zirconia, le silicon nitride, joalo-joalo.

Lihlahisoa tsa rona tsa mantlha li kenyelletsa: silicon carbide etching disc, silicon carbide boat tow, silicon carbide wafer boat (Photovoltaic&Semiconductor), silicon carbide furnace tube, silicon carbide cantilever paddle, silicon carbide chucks, silicon carbide beam, hammoho le CVD SiC coating le TaC. ho roala.Lihlahisoa tse sebelisoang haholo indastering ea semiconductor le photovoltaic, joalo ka lisebelisoa tsa kholo ea kristale, epitaxy, etching, ho paka, ho roala le libono tsa phallo, jj.

Khampani ea rona e na le lisebelisoa tse feletseng tsa tlhahiso tse kang ho bōpa, ho etsa sintering, ho sebetsa, lisebelisoa tsa ho roala, joalo-joalo, tse ka tlatsang lihokelo tsohle tse hlokahalang tsa tlhahiso ea lihlahisoa le ho ba le taolo e phahameng ea boleng ba sehlahisoa;Morero o nepahetseng oa tlhahiso o ka khethoa ho ea ka litlhoko tsa sehlahisoa, ho fella ka theko e tlaase le ho fa bareki lihlahisoa tse ngata tsa tlhōlisano;Re ka khona ho hlophisa tlhahiso ka mokhoa o bonolo le ka katleho ho latela litlhoko tsa ho fana ka taelo le ka kopanelo le litsamaiso tsa taolo ea odara ea inthaneteng, ho fa bareki nako e potlakileng le e netefalitsoeng ea ho fana ka nako.

-

Thermal insulation graphite carbon faeba faeba e thata e utloahala

-

Sekepe sa silicon carbide wafer

-

Bohloeki bo phahameng ba SiC Carrier / Susceptor

-

Mocheso o phahameng o hanyetsanang le silicon carbide cera...

-

Silicon carbide seal ring Silicon carbide press...

-

SIC special high pure pure graphite crucible 6-inc...