CVD SiC ke eng

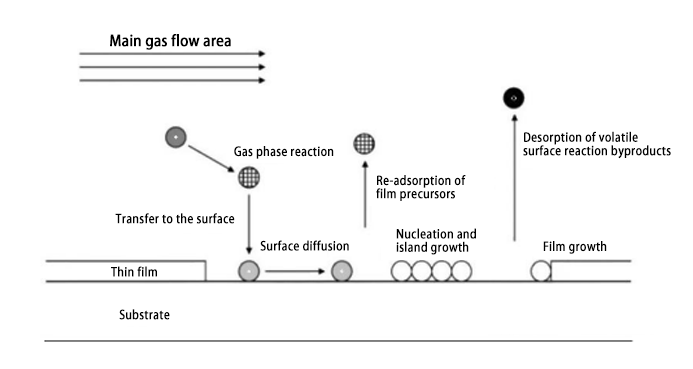

Chemical vapor deposition (CVD) ke ts'ebetso ea vacuum deposition e sebelisetsoang ho hlahisa lisebelisoa tse tiileng tse hloekileng. Ts'ebetso ena e atisa ho sebelisoa tšimong ea tlhahiso ea semiconductor ho etsa lifilimi tse tšesaane holim'a li-wafers. Ha ho ntse ho lokisoa SiC ka CVD, substrate e pepesehile ho li-precursors tse le 'ngoe kapa tse ngata, tse sebetsanang le lik'hemik'hale holim'a substrate ho kenya depositi e lakatsehang ea SiC. Har'a mekhoa e mengata ea ho lokisetsa lisebelisoa tsa SiC, lihlahisoa tse lokiselitsoeng ke ho kenngoa ha mouoane oa lik'hemik'hale li na le ho tšoana ho phahameng le ho hloeka, 'me mokhoa ona o na le matla a ho laola ts'ebetso.

Lisebelisoa tsa CVD SiC li loketse haholo ho sebelisoa indastering ea semiconductor e hlokang lisebelisoa tse phahameng tsa ts'ebetso ka lebaka la motsoako o ikhethang oa thepa e babatsehang ea mocheso, motlakase le lik'hemik'hale. Likarolo tsa CVD SiC li sebelisoa haholo ho lisebelisoa tsa etching, lisebelisoa tsa MOCVD, lisebelisoa tsa Si epitaxial le lisebelisoa tsa SiC epitaxial, lisebelisoa tse potlakileng tsa ho sebetsa ka mocheso le likarolo tse ling.

Ka kakaretso, karolo e kholo ea 'maraka ea likarolo tsa CVD SiC e kenyelletsa lisebelisoa tsa lisebelisoa. Ka lebaka la ts'ebetso ea eona e tlase le conductivity ho likhase tse nang le chlorine le fluorine, CVD silicon carbide ke sesebelisoa se loketseng likarolo tse joalo ka mehele ea lisebelisoa tsa plasma etching.

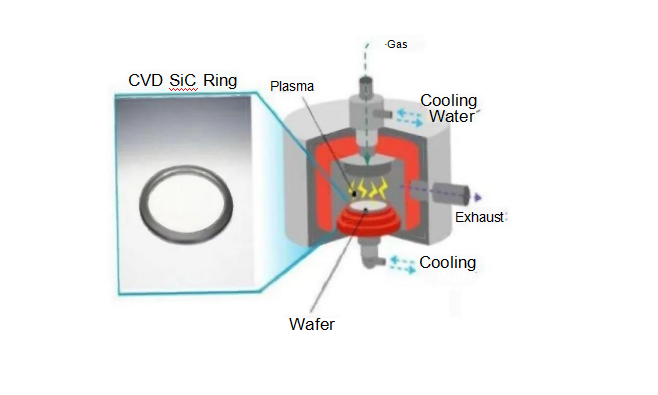

Likarolo tsa CVD silicon carbide ka thepa ea etching li kenyelletsa mehele ea ho tsepamisa maikutlo, lihlooho tsa ho hlapa ka khase, li-trays, mehele e bohale, joalo-joalo Ho nka lesale la ho tsepamisa mohopolo e le mohlala, selikalikoe sa ho tsepamisa maikutlo ke karolo ea bohlokoa e behiloeng ka ntle ho sephaphatha le ho kopana ka ho toba le sephaphatha. Ka ho sebelisa motlakase ho selikalikoe ho shebana le plasma e fetang ka selikalikoe, plasma e tsepamisitsoe holim'a sephaphatha ho ntlafatsa ts'ebetso e ts'oanang.

Mehele ea setso e tsepamisitsoeng e entsoe ka silicon kapa quartz. Ka tsoelo-pele ea "circuit miniaturization" e kopaneng, tlhoko le bohlokoa ba lits'ebetso tsa etching tlhahisong e kopaneng ea potoloho lia eketseha, 'me matla le matla a etching plasma a ntse a eketseha. Haholo-holo, matla a plasma a hlokehang ho thepa ea etching ea plasma ea capacitively couplely (CCP) a phahame, ka hona, sekhahla sa tšebeliso ea mehele e entsoeng ka thepa ea silicon carbide e ntse e eketseha. Setšoantšo sa moralo oa selikalikoe sa CVD silicon carbide se bontšitsoe ka tlase:

Nako ea poso: Jun-20-2024