Carbon ke e 'ngoe ea lintho tse atileng haholo tlhahong, e kenyelletsang thepa ea hoo e batlang e le lintho tsohle tse fumanehang Lefatšeng. E bonts'a mefuta e mengata ea litšoaneleho, joalo ka boima bo fapaneng le bonolo, boits'oaro ba insulation-semiconductor-superconductor, mocheso oa mocheso-superconductivity, le khanya e felletseng ea ho monya. Har'a tsena, lisebelisoa tse nang le sp2 hybridization ke litho tsa mantlha tsa lelapa la thepa ea khabone, ho kenyeletsoa graphite, carbon nanotubes, graphene, fullerenes, le amorphous glassy carbon.

Mehlala ea Khabone ea Graphite le Khalase

Le hoja lisebelisoa tse fetileng li tsebahala, a re shebeng khabone ea khalase kajeno. Khabone ea khalase, eo hape e tsejoang e le khalase ea khabone kapa vitreous carbon, e kopanya thepa ea khalase le lirafshoa hore e be thepa ea khabone e seng ea graphitic. Ho fapana le graphite ea kristale, ke thepa ea carbon ea amorphous e batlang e le 100% sp2-hybridized. Khabone e entsoeng ka khalase e entsoe ka mocheso o phahameng oa li-precursor organic compounds, joalo ka li-phenolic resin kapa furfuryl alcohol resin, tlas'a sepakapaka sa khase e sa sebetseng. Ponahalo ea eona e ntšo le bokaholimo bo boreleli bo kang ba khalase bo ile ba etsa hore e bitsoe "khabone ea khalase".

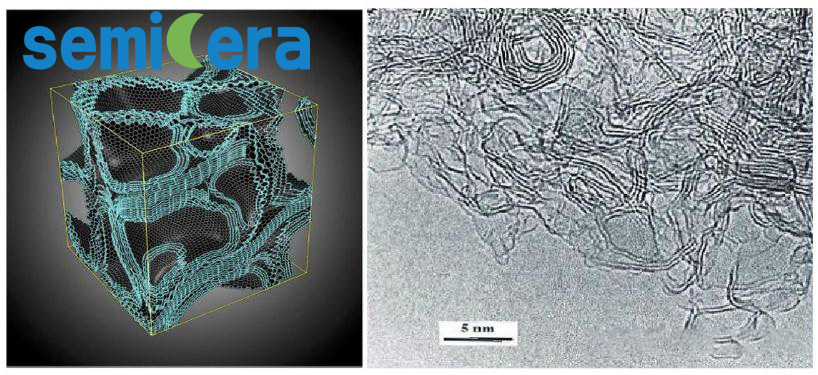

Ho tloha ha bo-rasaense ba qala ho qapa ka 1962, sebopeho le thepa ea khabone ea khalase e 'nile ea ithutoa haholo' me e ntse e le taba e chesang tšimong ea lisebelisoa tsa carbon. Khabone ea khalase e ka aroloa ka mefuta e 'meli: Mofuta oa I le Mofuta oa II oa khabone ea khalase. K'habone ea mofuta oa I e tšeloa ho tsoa ho li-precursors tsa tlhaho mochesong o ka tlase ho 2000 ° C 'me e na haholo-holo ka likhechana tsa graphene tse kobehileng. Ka lehlakoreng le leng, k'habone ea khalase ea mofuta oa II e tšeloa mochesong o phahameng (~ 2500 ° C) 'me e theha matrix a amorphous multilayered three-dimensional matrix a ikemetseng a kopaneng a chitja a kang a fullerene (joalokaha ho bontšitsoe setšoantšong se ka tlase).

Boemeli ba Sebopeho sa Khabone ea Khalase (Ka ho le letšehali) le Setšoantšo se Phahameng sa Elektrone sa Microscopy (Ka ho le letona)

Liphuputso tsa morao-rao li fumane hore mofuta oa II oa khabone ea khalase o bonts'a ho hatelloa ho hoholo ho feta Mofuta oa I, o hlahisoang ke meaho ea eona e chitja e ikopaneng ea fullerene. Leha ho na le liphapang tse nyane tsa jiometri, bobeli ba mofuta oa I le mofuta oa II oa makhabone a khalase ha e le hantle a entsoe ka graphene e kobehileng e sa sebetseng.

Lisebelisoa tsa Khabone ea Khalase

Khabone ea khalase e na le lintho tse ngata tse hlahelletseng, ho kenyeletsoa boima bo tlase, boima bo phahameng, matla a phahameng, ho se khone ho kenella ka har'a likhase le maro, botsitso bo phahameng ba mocheso le lik'hemik'hale, tse etsang hore e sebelisoe haholo liindastering tse kang tlhahiso, k'hemistri le lisebelisoa tsa elektroniki.

01 Likopo tsa Mocheso o Phahameng

Khabone ea khalase e bonts'a khanyetso ea mocheso o phahameng ka har'a khase e sa sebetseng kapa tikolohong ea vacuum, e mamella mocheso o fihlang ho 3000°C. Ho fapana le lisebelisoa tse ling tsa ceramic le tšepe tse nang le mocheso o phahameng, matla a khabone ea khalase a eketseha ka mocheso mme a ka fihla ho 2700K ntle le ho senyeha. E boetse e na le boima bo tlase, ho monya mocheso o tlase, le katoloso e tlase ea mocheso, e e etsa hore e tšoanelehe bakeng sa lits'ebetso tse fapaneng tsa mocheso o phahameng, ho kenyeletsoa li-tubes tsa ts'ireletso ea thermocouple, lits'ebetso tsa ho kenya le lisebelisoa tsa sebōpi.

02 Lisebelisoa tsa Lik'hemik'hale

Ka lebaka la khanyetso ea eona e phahameng ea kutu, khabone ea khalase e fumana ts'ebeliso e kholo tlhahlobong ea lik'hemik'hale. Thepa e entsoeng ka khabone ea khalase e fana ka melemo ho feta lisebelisoa tse tloaelehileng tsa laboratori tse entsoeng ka polatinamo, khauta, litšepe tse ling tse hananang le ho bola, lirafshoa tse khethehileng, kapa fluoroplastics. Melemo ena e kenyelletsa ho hanyetsa lisebelisoa tsohle tse senyang metsi, ha ho na phello ea mohopolo (ho sa laoleheng adsorption le desorption ea likarolo), ha ho na tšilafalo ea lisampole tse hlahlobiloeng, ho hanyetsa li-acids le ho qhibiliha ha alkaline, le bokaholimo ba khalase e seng porous.

03 Theknoloji ea Meno

Lithako tsa khabone tsa khalase li sebelisoa hangata ho theknoloji ea meno bakeng sa ho qhibilihisa litšepe tsa bohlokoa le li-alloys tsa titanium. Li fana ka melemo e joalo ka conductivity e phahameng ea mocheso, nako e telele ea bophelo ha e bapisoa le li-crucibles tsa graphite, ha ho na tšepe ea tšepe ea bohlokoa e qhibilihisitsoeng, ho hanyetsa mocheso oa mocheso, ho sebetsa ho lirafshoa tsohle tsa bohlokoa le li-alloys tsa titanium, ts'ebeliso ea li-centrifuges tsa induction, pōpo ea moea o sireletsang holim'a tšepe e qhibilihisitsoeng, le ho felisa tlhokeho ea phallo.

Tšebeliso ea likhalase tsa carbon crucibles e fokotsa nako ea ho futhumatsa le ho qhibiliha 'me e lumella likhoele tse futhumatsang tsa yuniti e qhibilihang hore li sebetse ka mocheso o tlase ho feta lijana tsa khale tsa ceramic, ka hona li fokotsa nako e hlokahalang bakeng sa ho lahla le ho lelefatsa nako ea bophelo ea crucible. Ho feta moo, ho se be metsi ha eona ho felisa matšoenyeho a tahlehelo ea thepa.

04 Likopo tsa Semiconductor

Khabone ea khalase, e nang le bohloeki bo phahameng, e hanyetsanang le kutu e ikhethang, ho ba sieo ha tlhahiso ea likaroloana, conductivity, le thepa e ntle ea mochini, ke thepa e loketseng tlhahiso ea semiconductor. Li-crucibles le liketsoana tse entsoeng ka khabone ea khalase li ka sebelisoa bakeng sa ho qhibilihisa likarolo tsa semiconductor ho sebelisoa mekhoa ea Bridgman kapa Czochralski, synthesis ea gallium arsenide, le kholo ea kristale e le 'ngoe. Ho feta moo, khabone ea khalase e ka sebetsa e le likarolo tsa sistimi ea ho kenya ion le li-electrode lits'ebetsong tsa plasma etching. Ponaletso ea eona e phahameng ea X-ray e boetse e etsa hore likhase tsa khabone tsa khalase li tšoanele li-substrates tsa mask a X-ray.

Qetellong, khabone ea khalase e fana ka thepa e ikhethang e kenyelletsang ho hanyetsa mocheso o phahameng, ho se sebetse ha lik'hemik'hale, le ts'ebetso e ntle ea mochine, e etsang hore e tšoanelehe bakeng sa mefuta e mengata ea likopo liindastering tse sa tšoaneng.

Ikopanye le Semicera bakeng sa lihlahisoa tsa khabone tsa khalase.

Lengolo-tsoibila:sales05@semi-cera.com

Nako ea poso: Dec-18-2023