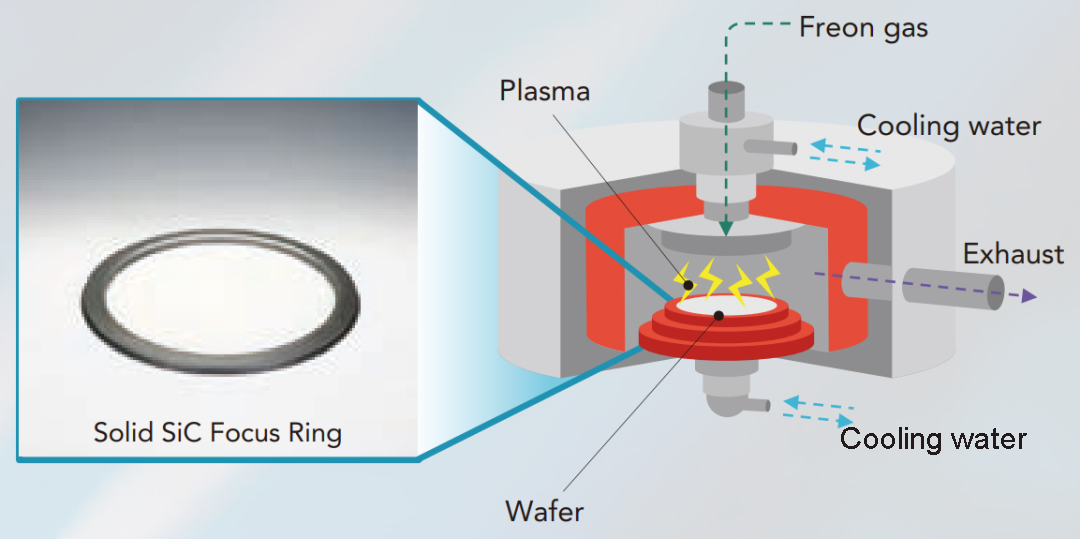

Lisebelisoa tsa plasma etching, likarolo tsa ceramic li bapala karolo ea bohlokoa, ho kenyelletsa leselikalikoe sa ho tsepamisa maikutlo.The selikalikoe sa ho tsepamisa maikutlo, e behiloeng ho pota-potile sephaphatha le ho kopana le eona ka ho toba, ke ea bohlokoa bakeng sa ho lebisa plasma holim'a sephaphatha ka ho sebelisa motlakase ho lesale. Sena se ntlafatsa ho tšoana ha mokhoa oa etching.

Tšebeliso ea SiC Focus Rings ho Etching Machines

Likarolo tsa SiC CVDmecheng ea etching, joalo kamehele e tsepameng, lishaoara tsa khase, li-platens, le mehele e ka thōko, li ratoa ka lebaka la ts'ebetso e tlaase ea SiC e nang le chlorine le fluorine-based etching gases le conductivity ea eona, e leng se etsang hore e be thepa e loketseng bakeng sa lisebelisoa tsa plasma etching.

Melemo ea SiC joalo ka Sesebelisuoa sa Ring sa Focus

Ka lebaka la ho pepeseha ka kotloloho ho plasma ka phaposing ea vacuum reaction, mehele e tlameha ho etsoa ka thepa e hananang le plasma. Masale a khale a tsepamisitsoeng maikutlo, a entsoeng ka silicon kapa quartz, a na le bothata ba ho hanyetsa etching ho plasma e thehiloeng ho fluorine, e lebisang ho kutu ka potlako le ho fokotseha ha ts'ebetso.

Papiso lipakeng tsa Si le CVD SiC Focus Rings:

1. Tekano e Phahameng:E fokotsa molumo oa molumo.

2. Wide Bandgap: E fana ka insulation e ntle haholo.

3. High Thermal Conductivity & Low Katoloso Coefficient: E hanyetsanang le mocheso oa mocheso.

4. Matla a Phahameng:Ho hanyetsa hantle ho ts'usumetso ea mochine.

5. Matla a Phahameng: E sa jeng le ho bola.

SiC e arolelana motlakase oa silicon ha e ntse e fana ka khanyetso e phahameng ho etching ea ionic. Ha "circuit miniaturization" e kopaneng e ntse e tsoela pele, tlhokahalo ea lits'ebetso tse sebetsang hantle tsa etching ea eketseha. Lisebelisoa tsa plasma etching, haholo tse sebelisang plasma ea capacitive coupled (CCP), li hloka matla a phahameng a plasma, ho etsaSiC tsepamiso mehelee tumme haholo.

Si le CVD SiC Focus Ring Parameters:

| Paramethara | Silicon (Si) | CVD Silicon Carbide (SiC) |

| Boima ba 'mele (g/cm³) | 2.33 | 3.21 |

| Band Gap (eV) | 1.12 | 2.3 |

| Thermal Conductivity (W/cm°C) | 1.5 | 5 |

| Mocheso oa Katoloso ea Mocheso (x10⁻⁶/°C) | 2.6 | 4 |

| Elastic Modulus (GPA) | 150 | 440 |

| Ho thatafala | Tlase | E phahameng |

Ts'ebetso ea Tlhahiso ea SiC Focus Rings

Lisebelisoa tsa semiconductor, CVD (Chemical Vapor Deposition) e atisa ho sebelisoa ho hlahisa likarolo tsa SiC. Masale a ho tsepamisa maikutlo a entsoe ka ho kenya SiC libopeho tse ikhethileng ka ho beha mouoane, ebe ho lateloa ke ts'ebetso ea mochini ho etsa sehlahisoa sa ho qetela. Karolelano ea thepa bakeng sa ho beha mouoane e tsitsitse ka mor'a liteko tse ngata, ho etsa hore liparamente tse kang resistivity li lumellane. Leha ho le joalo, lisebelisoa tse fapaneng tsa etching li ka hloka mehele e nang le mehano e fapaneng, e hlokang liteko tse ncha tsa karo-karolelano ea thepa bakeng sa tlhaloso e 'ngoe le e' ngoe, e jang nako ebile e bitsa chelete e ngata.

Ka ho khethaSiC tsepamiso meheleho tlohaSemiconductor ea semicera, bareki ba ka fumana melemo ea lipotoloho tse telele tse ncha le ts'ebetso e phahameng ntle le keketseho e kholo ea litšenyehelo.

Likarolo tsa Ts'ebetso e potlakileng ea Thermal (RTP).

Thepa e ikhethang ea CVD SiC e etsa hore e loketse lits'ebetso tsa RTP. Likarolo tsa RTP, ho kenyelletsa le mehele e bohale le li-platen, li rua molemo ho CVD SiC. Nakong ea RTP, likhahla tse matla tsa mocheso li sebelisoa ho li-wafers ka nako e khuts'oane, ebe li lateloa ke ho pholisa ka potlako. Mehele ea bohale ea CVD SiC, e le tšesaane ebile e na le boima bo tlaase ba mocheso, ha e boloke mocheso o moholo, e leng se etsang hore e se ke ea ameha ka ho futhumatsa le ho pholisa ka potlako.

Likarolo tsa ho Etching Plasma

Khanyetso e phahameng ea lik'hemik'hale ea CVD SiC e etsa hore e loketse lits'ebetso tsa etching. Likamore tse ngata tsa etching li sebelisa lipoleiti tsa phepelo ea khase ea CVD SiC ho aba likhase tse etching, tse nang le masoba a manyane a likete bakeng sa ho hasana ha plasma. Ha ho bapisoa le lisebelisoa tse ling, CVD SiC e na le reactivity e tlase e nang le chlorine le likhase tsa fluorine. Ho etching e omeletseng, likarolo tsa CVD SiC joalo ka mehele ea ho tsepamisa maikutlo, lipoleiti tsa ICP, mehele ea moeli, le li-shawaerheads li sebelisoa hangata.

Li-ring tse shebaneng tsa SiC, tse nang le matla a tsona a sebelisoang bakeng sa ho tsepamisa maikutlo ho plasma, li tlameha ho ba le conductivity e lekaneng. Ka tloaelo e entsoe ka silicon, mehele e tsepamisisang maikutlo e pepesetsoa likhase tse sebetsang tse nang le fluorine le chlorine, e lebisang ho kutu e ke keng ea qojoa. Mehele ea SiC, e nang le khanyetso e phahameng ea kutu, e fana ka nako e telele ea bophelo ha e bapisoa le mehele ea silicon.

Papiso ea Lifecycle:

· SiC Focus Rings:E fetoleloa ka matsatsi a 15 ho isa ho a 20.

· Silicon Focus Rings:E fetoleloa ka matsatsi a 10 ho isa ho a 12.

Leha mehele ea SiC e theko e phahameng ka makhetlo a 2 ho isa ho a 3 ho feta mehele ea silicon, potoloho e atolositsoeng ea phetisetso e fokotsa litšenyehelo tsa phetolo ea likarolo, kaha likarolo tsohle tsa phaposi li nkeloa sebaka ka nako e le 'ngoe ha kamore e buloa bakeng sa ho khutlisa selikalikoe.

Semicera Semiconductor's SiC Focus Rings

Semicera Semiconductor e fana ka mehele ea SiC ka litheko tse haufi le tsa mehele ea silicon, ka nako ea pele ea matsatsi a ka bang 30. Ka ho kopanya mehele ea Semicera ea SiC ka har'a lisebelisoa tsa plasma etching, katleho le bophelo bo bolelele li ntlafatsoa haholo, ho fokotsa litšenyehelo tsa tlhokomelo ka kakaretso le ho ntlafatsa katleho ea tlhahiso. Ho feta moo, Semicera e khona ho etsa hore ho be le mehele ea ho tsepamisa maikutlo ho fihlela litlhoko tse khethehileng tsa bareki.

Ka ho khetha mehele ea SiC e tsoang ho Semicera Semiconductor, bareki ba ka fumana melemo ea lipotoloho tse telele tse ncha le ts'ebetso e phahameng ntle le keketseho e kholo ea litšenyehelo.

Nako ea poso: Jul-10-2024