[Tlhaloso e akaretsang] Khatello ea sepakapaka e kentsesilicon carbideke carbide e seng tšepe e kopantsoeng le silicon le carbon covalent bonds, 'me boima ba eona ke ba bobeli feela ho daemane le boron carbide. Foromo ea lik'hemik'hale ke SiC. Likristale tse se nang mebala, tse putsoa le tse ntšo ka chebahalo ha li na le oxidized kapa li na le litšila.

Khatello ea sepakapaka e ile ea fokotsehasilicon carbideke carbide e seng tšepe e nang le silicon le carbon covalent bond, 'me boima ba eona ke ba bobeli feela ho daemane le boron carbide. Foromo ea lik'hemik'hale ke SiC. Likristale tse se nang mebala, tse putsoa le tse ntšo ka chebahalo ha li na le oxidized kapa li na le litšila. The deformation easilicon carbideka sebopeho sa taemane ka kakaretso se bitsoa emery. Ho thatafala ha emery ho haufi le daemane, botsitso bo botle ba mocheso, bo tsitsitseng ho hydroxy acid aqueous solution le concentrated sulfuric acid, le ho se tsitse ho acid e tsoakiloeng kapa phosphoric acid ea concentrated hydrogen acid le nitric acid. Li-alkali tse qhibilihang sebakeng se sekoti lia fapana. E arotsoe ka maiketsetsosilicon carbidele silicon carbide ea tlhaho. Natural silicon carbide, e tsejoang e le carbonite, e fumanoa haholo-holo ho kimberlite le volcanic amphibolite, empa palo ea eona e nyenyane ebile ha e na boleng ba ho epolloa.

Khatello ea sepakapaka ea indasteri e ile ea fokotsehasilicon carbideke motsoako oa -SiC le -SiC mme e tla ka mebala e 'meli: e ntšo le e tala. Silicone carbide e hloekileng ha e na 'mala, e nang le litšila tse ntšo, tse tala, tse putsoa, tse mosehla. Meeli ea lijo-thollo tse hexagonal le li-cubic, kristale ke poleiti, kholomo e kopaneng. Khalase e khanyang, density 3.17-3.47G / CM3, Morse hardness 9.2, microscope e boetse e le 30380 ~ 33320MPa melting point: atmosfere 2050 e ile ea qala ho khetholla, moea oa ho hlaphoheloa 2600 o ile oa qala ho arohana. Elastic coefficient ke 466, 480MPa. Matla a matla ke 171.5MPa. Matla a hatellang ke 1029MPa. Mohala oa ho atolosa coefficient ke (25~ 1000) 5.010 ~ 6/, 'me conductivity ea mocheso (20) ke 59w/(mk). Ho tsitsa ha lik'hemik'hale, ho belisoa ho HCI, H2SO4, HF e ke ke ea senyeha.

Ho ea ka litšebeliso tse fapaneng, khatello ea sepakapaka sintered silicon carbide e arotsoe ka data ea abrasive, refractory, deoxidizer, silicon carbide ea motlakase joalo-joalo. Likahare tsa SiC tsa abrasive silicon carbide ha lia lokela ho ba ka tlase ho 98%. Li-refractories tse nang le silicon carbide li arotsoe ka: (1) data e tsoetseng pele ea refractory black silicon carbide, litaba tsa eona tsa SiC li tšoana hantle le ho sila silicon carbide. (2) Lintlha tsa bobeli tsa refractory silicon carbide, dikahare tsa SiC tse fetang 90%. (3) Likahare tsa silicon carbide e ntšo le SiC ho li-refractories tsa boemo bo tlaase ha li ka tlase ho 83%. Likahare tsa silicon carbide le SiC tse sebelisoang ho deoxidizer hangata li hlokoa hore li be ka holimo ho 90%. Leha ho le joalo, k'habone indasteri graphitization sebōpi insulation, silicon carbide dikahare tse fetang 45% ea phekolo ka boela sebelisoa e le steelmaking deoxidizer. Silicon carbide bakeng sa deoxidizing agent e na le mefuta e 'meli ea sebopeho sa phofo le block block. Powder deoxidizer black silicon carbide ka kakaretso e na le boholo ba karolo ea 4 ~ 0.5 mm le 0.5 ~ 0.1 mm. Silicon carbide ea tšebeliso ea motlakase e na le mekhahlelo e 'meli e meholo. (1) Silicon carbide e tala e sebelisetsoang ho futhumatsa lisebelisoa tsa motlakase e hlile e tšoana le silicon carbide e tala e sebelisetsoang ho sila. (2) Silicon carbide bakeng sa ho ts'oaroa e na le litlhoko tse khethehileng tsa ts'ebetso ea motlakase, e fapaneng le silicon carbide e ntšo bakeng sa ho sila data ea refractory.

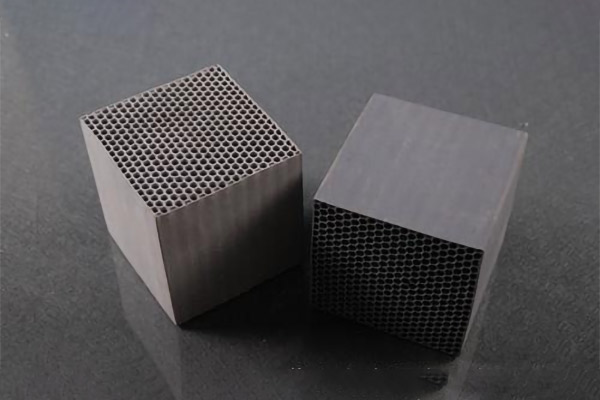

Tšebeliso ea khatello ea sepakapaka sintered silicon carbide

Atmospheric pressure sintered silicon carbide lihlahisoa li na le mesebetsi e khethehileng e kang ho hanyetsa mocheso o phahameng, ho hanyetsa mocheso, ho hanyetsa mocheso, ho hanyetsa mollo, ho hanyetsa mahlaseli, ho sebetsa hantle ha motlakase le mocheso, joalo-joalo, 'me li sebelisitsoe haholo mafapheng a sa tšoaneng a moruo oa naha. Chaena, silicon carbide e tala e sebelisoa haholo-holo e le abrasive. Silicon carbide e ntšo e sebelisoa ho etsa majoe a sila, ao hangata a sebelisetsoang ho seha le ho sila lisebelisoa tse nang le matla a fokolang a kang khalase, lirafshoa, majoe, li-refractories, hammoho le ho sila likarolo tsa tšepe tse entsoeng ka tšepe le lisebelisoa tsa tšepe tse se nang ferrous. Sila e entsoeng ka silicon carbide e tala e sebelisoa haholo bakeng sa ho sila carbide e entsoeng ka samente, alloy ea titanium, khalase ea optical, hape le bakeng sa ho sila li-cylinder liner le lisebelisoa tsa tšepe tse lebelo le phahameng. Li-abrasives tsa cubic silicon carbide li sebelisoa feela bakeng sa ho sila ka ho nepahala ha li-bearings tse nyane. Ho hanyetsa ho roala ha li-turbine impellers ho ka ntlafatsoa haholo ka ho sebelisa phofo ea SIC ho tsona ka electroplating. U sebelisa khatello ea mochine ho sutumelletsa leloala la li-cubic SiC200 le phofo e nyenyane ea W28 leboteng la cylinder ea enjene e tukang e ka hare, bophelo ba silindara bo ka imena habeli.

Nako ea poso: Oct-11-2023