Li-substrates tsa Silicon carbide (SiC) li na le liphoso tse ngata tse thibelang ts'ebetso e tobileng. Ho theha li-chip wafers, filimi e khethehileng ea kristale e le 'ngoe e tlameha ho holisoa holim'a substrate ea SiC ka mokhoa oa epitaxial. Filimi ena e tsejoa e le epitaxial layer. Hoo e ka bang lisebelisoa tsohle tsa SiC li lemohuoa ka thepa ea epitaxial, 'me lisebelisoa tsa boleng bo holimo tsa homoepitaxial SiC li theha motheo oa nts'etsopele ea sesebelisoa sa SiC. Ts'ebetso ea lisebelisoa tsa epitaxial ka ho toba e etsa qeto ea ts'ebetso ea lisebelisoa tsa SiC.

Lisebelisoa tsa SiC tsa morao-rao le tse ts'eptjoang haholo li beha litlhoko tse thata ho morphology ea bokaholimo, bofokoli ba sekoli, ho ts'oana ha li-doping le ho lekana ha botenya.epitaxiallisebelisoa. Ho fihlella boholo bo boholo, bofokoli bo fokolang, le boemo bo phahameng ba SiC epitaxy e fetohile ea bohlokoa bakeng sa nts'etsopele ea indasteri ea SiC.

Ho hlahisa epitaxy ea boleng bo holimo ea SiC ho itšetlehile ka mekhoa le lisebelisoa tse tsoetseng pele. Hona joale, mokhoa o sebelisoang ka ho fetisisa bakeng sa kholo ea SiC epitaxial keKemiso ea Mouoane oa Lik'hemik'hale (CVD).CVD e fana ka taolo e nepahetseng holim'a botenya ba filimi ea epitaxial le mahloriso a doping, sekhahla se tlase sa sekoli, sekhahla sa kholo e itekanetseng, le taolo ea ts'ebetso e ikemetseng, e etsang hore e be theknoloji e tšepahalang bakeng sa lits'ebetso tse atlehileng tsa khoebo.

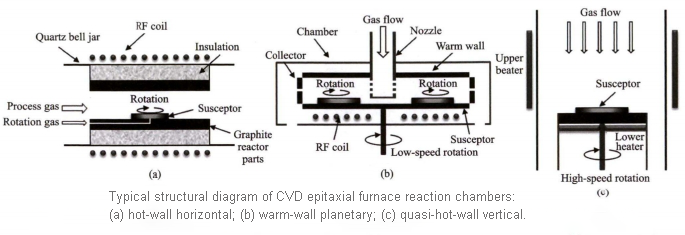

SiC CVD epitaxyka kakaretso e sebelisa lisebelisoa tsa CVD tsa lebota le chesang kapa lerako le futhumetseng. Lithempereichara tse phahameng tsa khōlo (1500-1700 ° C) li tiisa ho tsoela pele ha foromo ea 4H-SiC ea kristale. Ho ipapisitsoe le kamano pakeng tsa tataiso ea phallo ea khase le bokaholimo ba substrate, likamore tsa karabelo tsa litsamaiso tsena tsa CVD li ka aroloa ka meaho e otlolohileng le e emeng.

Boleng ba SiC epitaxial furnaces haholo-holo bo ahloloa ka likarolo tse tharo: ts'ebetso ea kholo ea epitaxial (ho kenyeletsoa ho lekana ha botenya, ho tšoana ha doping, sekhahla sa sekoli, le sekhahla sa kholo), ts'ebetso ea mocheso oa thepa (ho kenyeletsoa litekanyetso tsa ho futhumatsa / pholileng, mocheso o phahameng ka ho fetisisa, le ho tšoana ha mocheso. ), le ho boloka litšenyehelo (ho kenyeletsoa theko ea yuniti le bokhoni ba tlhahiso).

Phapang Pakeng tsa Mefuta e Meraro ea SiC Epitaxial Growth Furnaces

1.Hot-wall Horizontal CVD Systems:

-Likaroloana:Ka kakaretso e na le litsamaiso tsa kholo ea boholo bo boholo bo nang le sephaka se le seng se tsamaisoang ke ho potoloha ha moea oa khase, ho fihlela metrics e ntle haholo ea intra-wafer.

-Moemedi wa Mohlala:LPE's Pe1O6, e khonang ho kenya / ho laolla sephaphatha ka 900 ° C. E tsebahala ka litekanyetso tse phahameng tsa kholo, li-epitaxial cycles, le ts'ebetso e tsitsitseng ea intra-wafer le inter-run.

-Tshebetso:Bakeng sa li-wafers tsa 4-6 inch 4H-SiC epitaxial tse botenya ba ≤30μm, e fihlella botenya ba intra-wafer e sa ts'oaneng ≤2%, mahloriso a doping a sa ts'oaneng ≤5%, bokaholimo ba sekoli ≤1 cm-², 'me ha bo na sekoli. sebaka se ka holimo (lisele tse 2mm×2mm) ≥90%.

-Baetsi ba Lehae: Lik'hamphani tse kang Jingsheng Mechatronics, CETC 48, North Huachuang, le Nasset Intelligent li thehile lisebelisoa tse tšoanang tsa SiC tsa epitaxial tse nang le sephali se le seng tse nang le tlhahiso e phahameng.

2.Mofuthu-wall Planetary CVD Systems:

-Likaroloana:Sebelisa metheo ea tlhophiso ea lipolanete bakeng sa kholo ea li-wafer tse ngata betch ka 'ngoe, ho ntlafatsa ts'ebetso e ntle haholo ea tlhahiso.

-Moemeli Mehlala:Aixtron's AIXG5WWC (8x150mm) le G10-SiC (9x150mm kapa 6x200mm) letoto.

-Tshebetso:Bakeng sa li-wafers tsa epitaxial tsa 6-inch 4H-SiC tse nang le botenya ba ≤10μm, li fihlella ho kheloha ha botenya ba inter-wafer ± 2.5%, botenya ba intra-wafer bo sa tshwaneng 2%, kheloha ea "inter-wafer doping concentration" ± 5%, le intra-wafer doping. concentration non-uniformity <2%.

-Mathata:Kamohelo e fokolang 'marakeng oa lehae ka lebaka la khaello ea data ea tlhahiso ea li-batch, litšitiso tsa tekheniki taolong ea mocheso le phallo, le R&D e tsoelang pele ntle le ts'ebetsong e kholo.

3. Quasi-hot-wall Vertical CVD Systems:

- Likaroloana:Sebelisa thuso ea kantle ea mochini bakeng sa ho potoloha ka lebelo le phahameng, ho fokotsa botenya ba moeli le ho ntlafatsa sekhahla sa kholo ea epitaxial, ka melemo ea tlhaho taolong ea bofokoli.

- Moemeli Mehlala:Nuflare's single-wafer EPIREVOS6 le EPIREVOS8.

-Tshebetso:E finyella litekanyetso tsa kholo ho feta 50μm/h, taolo ea bokooa ba bokaholimo bo ka tlase ho 0.1 cm-², le botenya ba intra-wafer le mahloriso a doping a sa ts'oaneng a 1% le 2.6% ka ho latellana.

-Ntlafatso ea Lehae:Likhamphani tse kang Xingsandai le Jingsheng Mechatronics li qapile lisebelisoa tse tšoanang empa ha li so fihlelle ts'ebeliso e kholo.

Kakaretso

E 'ngoe le e' ngoe ea mefuta e meraro ea lisebelisoa tsa SiC epitaxial kgolo e na le litšobotsi tse ikhethang 'me e nka likarolo tse khethehileng tsa mmaraka ho latela litlhoko tsa kopo. Hot-wall horizontal CVD e fana ka sekhahla sa kholo e potlakileng haholo le boleng bo leka-lekaneng le ho ts'oana empa e na le ts'ebetso e tlase ea tlhahiso ka lebaka la ts'ebetso ea sephaphatha se le seng. CVD ea polanete e futhumetseng ea lebota e ntlafatsa haholo ts'ebetso ea tlhahiso empa e tobane le liphephetso taolong ea li-wafer tse ngata. Quasi-hot-wall vertical CVD e ipabola taolong ea sekoli e nang le sebopeho se rarahaneng mme e hloka tlhokomelo e batsi le boiphihlelo ba ts'ebetso.

Ha indasteri e ntse e tsoela pele, ho ntlafatsa le ho ntlafatsa meaho ena ea lisebelisoa ho tla lebisa tlhophisong e ntlafalitsoeng le ho feta, ho bapala karolo ea bohlokoa ho fihlela litlhoko tse fapaneng tsa epitaxial wafer bakeng sa botenya le bofokoli.

Melemo le Mefokolo ea Mefuta e Fapaneng ea SiC Epitaxial Growth Furnaces

| Mofuta oa Sebōpi | Melemo | Mefokolo | Baetsi ba Moemeli |

| Hot-wall Horizontal CVD | Sekhahla sa ho hōla ka potlako, mohaho o bonolo, tlhokomelo e bonolo | Potoloho e khutšoanyane ea tlhokomelo | LPE (Italy), TEL (Japan) |

| Lerako le futhumetseng la Planetary CVD | Bokhoni bo phahameng ba tlhahiso, bo sebetsang hantle | Sebopeho se rarahaneng, taolo e thata ea ho tsitsa | Aixtron (Jeremane) |

| Quasi-hot-wall Vertical CVD | Taolo e ntle ea bofokoli, potoloho e telele ea tlhokomelo | Sebopeho se rarahaneng, se thata ho se hlokomela | Nuflare (Japan) |

Ka nts'etsopele e tsoelang pele ea indasteri, mefuta ena e meraro ea lisebelisoa e tla ntlafatsoa le ho ntlafatsoa, e leng se lebisang ntlafatsong e ntseng e ntlafatsoa e lumellanang le litlhaloso tse fapaneng tsa epitaxial wafer bakeng sa litlhoko tsa botenya le bofokoli.

Nako ea poso: Jul-19-2024