Kakaretso ea Ts'ebetso ea Semiconductor

Ts'ebetso ea semiconductor haholo-holo e kenyelletsa ho sebelisa mahlale a microfabrication le lifilimi ho hokahanya li-chips le likarolo tse ling ka har'a libaka tse fapaneng, joalo ka li-substrates le liforeimi. Sena se nolofatsa ho ntšoa ha li-terminals tse etellang pele le ho koalloa ka polasetiki e sireletsang sepakapaka ho theha kakaretso e kopaneng, e hlahisoang e le sebopeho sa mahlakore a mararo, qetellong e phethela mokhoa oa ho paka oa semiconductor. Khopolo ea ts'ebetso ea semiconductor e boetse e amana le tlhaloso e patisaneng ea semiconductor chip packaging. Ho latela pono e pharalletseng, e bua ka boenjiniere ba ho paka, bo kenyelletsang ho hokahanya le ho lokisa substrate, ho hlophisa lisebelisoa tsa elektroniki tse tsamaellanang, le ho aha sistimi e felletseng e nang le ts'ebetso e matla e felletseng.

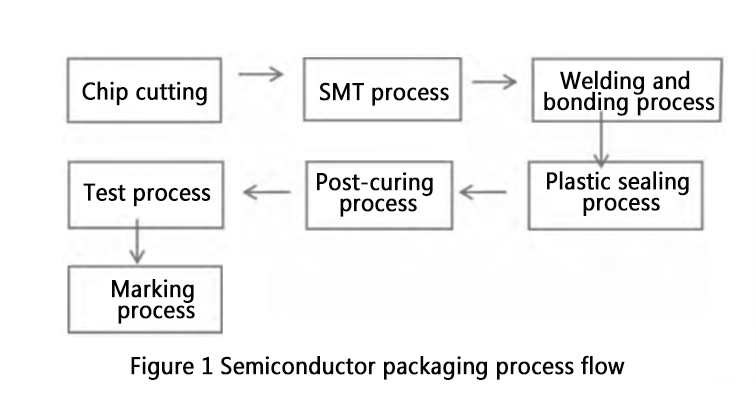

Semiconductor Packaging Process Flow

Ts'ebetso ea ho paka ea semiconductor e kenyelletsa mesebetsi e mengata, joalo ka ha e bonts'itsoe ho Setšoantšo sa 1. Ts'ebetso e 'ngoe le e' ngoe e na le litlhoko tse khethehileng le ts'ebetso e amanang haufi-ufi, e hlokang tlhahlobo e qaqileng nakong ea mohato o sebetsang. Litaba tse ikhethileng ke tse latelang:

1. Chip Cutting

Ts'ebetsong ea ho paka ka semiconductor, ho seha li-chip ho kenyelletsa ho seha li-wafers tsa silicon ka har'a lichifi ka bomong le ho tlosa lithōle tsa silicon hang-hang ho thibela litšitiso mosebetsing o latelang le taolo ea boleng.

2. Chip Mounting

Ts'ebetso ea ho kenya li-chip e shebana le ho qoba tšenyo ea potoloho nakong ea ho sila ka li-wafer ka ho sebelisa lesela le sireletsang la filimi, le lula le hatisa botšepehi ba potoloho.

3. Ts'ebetso ea Wire Bonding

Ho laola boleng ba ts'ebetso ea khokahanyo ea terata ho kenyelletsa ho sebelisa mefuta e fapaneng ea likhoele tsa khauta ho hokahanya liphaephe tsa bonding tsa chip le lipampiri tsa foreimi, ho netefatsa hore chip e khona ho hokela lipotolohong tsa kantle le ho boloka ts'ebetso e felletseng ea ts'ebetso. Ka tloaelo, ho sebelisoa lithapo tsa khauta tse nang le doped le lithapo tsa khauta tse kopantsoeng.

Lithapo tsa Khauta tse Doped: Mefuta e kenyelletsa GS, GW, le TS, e loketseng boemo bo phahameng ba arc (GS: > 250 μm), arc e phahameng e mahareng (GW: 200-300 μm), le arc e tlase e mahareng (TS: 100-200). μm) tlamahano ka ho latellana.

Lithapo tsa Khauta tse Alloyed: Mefuta e kenyelletsa AG2 le AG3, e loketseng bonding e tlaase ea arc (70-100 μm).

Likhetho tsa bophara ba lithapo tsena li tloha ho 0.013 mm ho isa ho 0.070 mm. Ho khetha mofuta o nepahetseng le bophara bo ipapisitseng le litlhoko le maemo a ts'ebetso ho bohlokoa bakeng sa taolo ea boleng.

4. Molding Process

Potoloho e ka sehloohong linthong tsa ho bopa e kenyelletsa encapsulation. Ho laola boleng ba mokhoa oa ho bopa ho sireletsa likarolo, haholo-holo ho matla a ka ntle a bakang tšenyo e fapaneng. Sena se kenyelletsa tlhahlobo e phethahetseng ea likarolo tsa 'mele.

Ho sebelisoa mekhoa e meraro ea mantlha hajoale: ho paka ka ceramic, ho paka polasetiki, le ho paka ka setso. Ho laola karolo ea mofuta o mong le o mong oa sephutheloana ho bohlokoa ho fihlela litlhoko tsa tlhahiso ea li-chip lefatšeng ka bophara. Nakong ea ts'ebetso, ho hlokahala bokhoni bo felletseng, joalo ka ho futhumatsa chip le foreimi ea lead pele ho koaheloa ka resin ea epoxy, ho bopa le ho folisa ka mor'a hlobo.

5. Mokhoa oa ho Fokotsa ka Morao

Ka mor'a ts'ebetso ea ho bōptjoa, phekolo ea morao-rao e hlokahalang, e lebisang tlhokomelo ho tlosa lisebelisoa leha e le life tse feteletseng ho pota-pota ts'ebetso kapa sephutheloana. Taolo ea boleng ke ea bohlokoa ho qoba ho ama boleng ba ts'ebetso ka kakaretso le ponahalo.

6.Ts'ebetso ea Teko

Hang ha lits'ebetso tse fetileng li phethiloe, boleng bo akaretsang ba ts'ebetso bo tlameha ho lekoa ho sebelisoa mahlale a tsoetseng pele a tlhahlobo le lisebelisoa. Mohato ona o kenyelletsa ho rekota lintlha tse qaqileng, ho shebana le hore na chip e sebetsa ka tloaelo ho latela boemo ba eona ba ts'ebetso. Ka lebaka la theko e phahameng ea lisebelisoa tsa tlhahlobo, ho bohlokoa ho boloka taolo ea boleng methating eohle ea tlhahiso, ho kenyeletsoa tlhahlobo ea pono le tlhahlobo ea ts'ebetso ea motlakase.

Teko ea Ts'ebetso ea Motlakase: Sena se kenyelletsa tlhahlobo ea li-circuits tse kopaneng tse sebelisang lisebelisoa tsa tlhahlobo ea othomathike le ho netefatsa hore potoloho ka 'ngoe e hokahane hantle bakeng sa tlhahlobo ea motlakase.

Tlhahlobo ea Pono: Litsebi li sebelisa li-microscopes ho hlahloba ka botlalo li-chips tse phethiloeng ho netefatsa hore ha li na bofokoli le ho fihlela litekanyetso tsa boleng ba semiconductor.

7. Mokhoa oa ho tšoaea

Ts'ebetso ea ho tšoaea e kenyelletsa ho fetisetsa lichipisi tse lekiloeng sebakeng sa polokelo se seng se felile bakeng sa ts'ebetso ea ho qetela, tlhahlobo ea boleng, ho paka le ho romelloa. Ts'ebetso ena e kenyelletsa mehato e meraro ea mantlha:

1) Electroplating: Ka mor'a ho etsa li-lead, ho sebelisoa thepa e thibelang ho bola ho thibela oxidation le corrosion. Theknoloji ea ho beha li-electroplating hangata e sebelisoa kaha litopo tse ngata li entsoe ka thini.

2) Ho Kobeha: Likarolo tse hlophisitsoeng li bōptjoa, 'me lesela le kopantsoeng la potoloho le kenngoa ka har'a sesebelisoa sa ho etsa lead, se laolang sebopeho sa pele (mofuta oa J kapa L) le sephutheloana se holim'a metsi.

3) Khatiso ea Laser: Qetellong, lihlahisoa tse entsoeng li hatisitsoe ka moralo, o sebetsang e le letšoao le ikhethileng bakeng sa ts'ebetso ea ho paka ka semiconductor, joalo ka ha ho bonts'itsoe ho Setšoantšo sa 3.

Mathata le Likhothaletso

Boithuto ba lits'ebetso tsa ho paka tsa semiconductor bo qala ka kakaretso ea theknoloji ea semiconductor ho utloisisa melao-motheo ea eona. Ka mor'a moo, ho hlahloba phallo ea ts'ebetso ea ho paka ho ikemiseditse ho netefatsa taolo e hlokolosi nakong ya ts'ebetso, ho sebelisa tsamaiso e hloekisitsoeng ho qoba mathata a tloaelehileng. Boemong ba nts'etsopele ea sejoale-joale, ho bohlokoa ho khetholla liphephetso lits'ebetsong tsa ho paka tsa semiconductor. Ho kgothaletswa ho tsepamisa maikutlo lintlheng tsa taolo ea boleng, ho tseba hantle lintlha tsa bohlokoa ho ntlafatsa boleng ba ts'ebetso ka katleho.

Ho sekaseka ho latela pono ea taolo ea boleng, ho na le mathata a bohlokoa nakong ea ts'ebetsong ka lebaka la lits'ebetso tse ngata tse nang le litaba le litlhoko tse ikhethang, e 'ngoe le e' ngoe e susumetsa e 'ngoe. Ho hlokahala taolo e matla nakong ea ts'ebetso e sebetsang. Ka ho ba le boikutlo bo hlokolosi ba ho sebetsa le ho sebelisa theknoloji e tsoetseng pele, boleng ba mokhoa oa ho paka ka semiconductor le maemo a tekheniki li ka ntlafatsoa, ho netefatsa katleho e felletseng ea ts'ebeliso le ho fumana melemo e metle ka kakaretso.(joalo ka ha ho bonts'itsoe ho Setšoantšo sa 3).

Nako ea poso: May-22-2024