Selelekela se le seng

Etching ka mokhoa o kopaneng oa tlhahiso ea potoloho e arotsoe ka:

- ho koloba ka metsi;

- Ho omella.

Matsatsing a pele, etching e metsi e ne e sebelisoa haholo, empa ka lebaka la mefokolo ea eona taolong ea bophara ba mela le tataiso ea etching, lits'ebetso tse ngata kamora 3μm li sebelisa etching e omileng. Etching e metsi e sebelisoa feela ho tlosa likarolo tse itseng tse khethehileng tsa thepa le masalla a hloekileng.

Dry etching e bolela ts'ebetso ea ho sebelisa li-etchants tsa lik'hemik'hale tse nang le khase ho sebetsana le lisebelisoa tse holim'a sephaphatha ho tlosa karolo ea thepa e lokelang ho tlosoa le ho etsa lihlahisoa tse fetohang, ebe li ntšoa ka kamoreng ea karabelo. Hangata Etchant e hlahisoa ka ho toba kapa ka tsela e sa tobang ho tsoa ho plasma ea khase ea etching, kahoo etching e omileng e boetse e bitsoa plasma etching.

1.1 Plasma

Plasma ke khase e boemong bo fokolang ba ionized e entsoeng ke ho khantša ha khase e etching ka tlas'a ts'ebetso ea sebaka sa kantle sa motlakase (joalo ka se hlahisoang ke motlakase oa maqhubu a seea-le-moea). E kenyelletsa lielektrone, li-ion le likaroloana tse sebetsang tse sa nke lehlakore. Har'a tsona, likaroloana tse sebetsang li ka itšoara ka ho toba ka lik'hemik'hale ka thepa e entsoeng ho finyella etching, empa karabelo ena e hloekileng ea lik'hemik'hale hangata e etsahala feela ka palo e nyenyane haholo ea lisebelisoa 'me ha e tataisoe; ha li-ion li e-na le matla a itseng, li ka kenngoa ka ho hlajoa ke 'mele ka ho toba, empa sekhahla sa ts'ebetso ena e hloekileng ea' mele se tlaase haholo 'me khetho e mpe haholo.

Boholo ba plasma etching bo phethoa ka ho kenya letsoho ha likaroloana tse sebetsang le li-ion ka nako e le 'ngoe. Ts'ebetsong ena, ho phatloha ha ion ho na le mesebetsi e 'meli. E 'ngoe ke ho senya maqhama a athomo holim'a thepa e entsoeng, ka hona ho eketsa lebelo leo likaroloana tse sa nke lehlakore li itšoarang ka tsona; e 'ngoe ke ho kokota lihlahisoa tsa karabelo tse behiloeng holim'a sebopeho sa karabelo ho nolofatsa etchant ho ikopanya ka botlalo le holim'a lintho tse entsoeng, e le hore etching e tsoele pele.

Lihlahisoa tsa karabelo tse kentsoeng mahlakoreng a sebopeho se hahelletsoeng li ke ke tsa tlosoa ka nepo ka ho phatloha ha li-ion tsa tataiso, ka hona ho thibela ho koaheloa ha mabota a mahlakoreng le ho etsa etching ea anisotropic.

Mokhoa oa bobeli oa etching

2.1 Metsi le ho Hloekisa

Wet etching ke e 'ngoe ea mahlale a khale ka ho fetesisa a sebelisoang tlhahisong e kopaneng ea potoloho. Leha lits'ebetso tse ngata tsa ho koloba tse metsi li nkeloe sebaka ke etching ea anisotropic e omileng ka lebaka la etching ea eona ea isotropic, e ntse e bapala karolo ea bohlokoa ho hloekiseng likarolo tse seng bohlokoa tsa boholo bo boholo. Haholo-holo ho etching ea masala a ho tlosa oxide le ho hlobolisa epidermal, e sebetsa hantle ebile e na le chelete e ngata ho feta ho omella.

Lintho tsa etching tse metsi haholo li kenyelletsa silicon oxide, silicon nitride, silicon e le 'ngoe ea kristale le silicon ea polycrystalline. Etching e metsi ea silicon oxide hangata e sebelisa hydrofluoric acid (HF) joalo ka eona e tsamaisang lik'hemik'hale. Bakeng sa ho ntlafatsa khetho, hlapolla hydrofluoric acid e buffered ke ammonium fluoride e sebelisoa ts'ebetsong. E le ho boloka botsitso ba pH ea boleng, tekanyo e nyenyane ea asiti e matla kapa likarolo tse ling li ka eketsoa. Doped silicon oxide e senyeha habonolo ho feta silicon oxide e hloekileng. Ho hlobolisa lik'hemik'hale tse metsi ho sebelisoa haholo ho tlosa photoresist le mask a thata (silicon nitride). Hot phosphoric acid (H3PO4) ke mokelikeli o ka sehloohong oa lik'hemik'hale o sebelisetsoang ho hlobolisa lik'hemik'hale tse metsi ho tlosa silicon nitride, 'me o na le khetho e ntle bakeng sa silicon oxide.

Ho hloekisa ka metsi ho tšoana le ho chesoa ha metsi, 'me haholo-holo ho tlosa litšila tse holim'a li-wafers tsa silicon ka liphetoho tsa lik'hemik'hale, ho akarelletsa le likaroloana, lintho tse phelang, tšepe le oxides. Mokhoa o tloaelehileng oa ho hloekisa ka metsi ke mokhoa oa lik'hemik'hale tse metsi. Le hoja ho hloekisa ka mokhoa o omileng ho ka nka sebaka sa mekhoa e mengata ea ho hloekisa ka metsi, ha ho na mokhoa o ka nkang sebaka sa ho hloekisa ka ho feletseng.

Lik'hemik'hale tse sebelisoang ka tloaelo bakeng sa ho hloekisa metsi li kenyelletsa sulfuric acid, hydrochloric acid, hydrofluoric acid, phosphoric acid, hydrogen peroxide, ammonium hydroxide, ammonium fluoride, joalo-joalo. Litšebelisong tse sebetsang, lik'hemik'hale tse le 'ngoe kapa ho feta li kopantsoe le metsi a deionized ka tekanyo e itseng ha ho hlokahala. etsa tharollo ea ho hloekisa, joalo ka SC1, SC2, DHF, BHF, joalo-joalo.

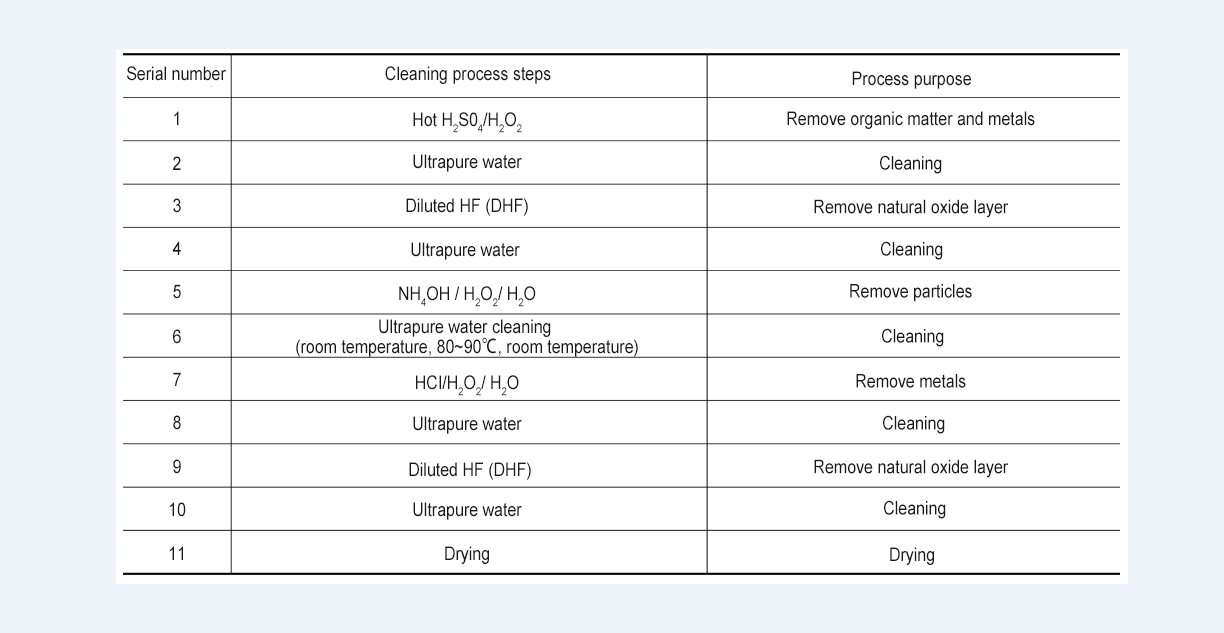

Ho hloekisa hangata ho sebelisoa ts'ebetsong pele ho beoa filimi ea oxide, hobane ho lokisoa ha filimi ea oxide ho tlameha ho etsoa holim'a sephaphatha sa silicon se hloekileng ka ho feletseng. Mokhoa o tloaelehileng oa ho hloekisa silicon oafer ke o latelang:

2.2 Dry Etching and Cleaning

2.2.1 Dry Etching

Etching e omileng indastering haholo-holo e bua ka etching ea plasma, e sebelisang plasma e nang le ts'ebetso e ntlafalitsoeng ho hlahisa lintho tse itseng. Sistimi ea lisebelisoa lits'ebetsong tse kholo tsa tlhahiso e sebelisa plasma e se nang tekano ea mocheso o tlase.

Plasma etching haholo-holo e sebelisa mekhoa e 'meli ea ho ntša metsi: capacitive colated discharge le inductive couple discharge.

Ka mokhoa oa capacitively coupled discharge mode: plasma e hlahisoa le ho bolokoa ka li-capacitor tse peli tse tšoanang ka motlakase oa kantle oa radio frequency (RF). Khatello ea khase hangata ke millitorr tse 'maloa ho ea ho mashome a millitorr,' me sekhahla sa ionization se ka tlase ho 10-5. Mokhoeng oa ho ntša o kopantsoeng ka inductively: hangata ka khatello e tlase ea khase (mashome a millitorr), plasma e hlahisoa le ho bolokoa ke matla a kenyelletsoeng a kopantsoeng ka mokhoa o tsitsitseng. Tekanyo ea ionization hangata e kholo ho feta 10-5, kahoo e boetse e bitsoa plasma e phahameng haholo. Mehloli ea plasma e phahameng haholo e ka boela ea fumanoa ka electron cyclotron resonance le cyclotron wave discharge. Plasma e phahameng haholo e ka ntlafatsa sekhahla sa etching le khetho ea ts'ebetso ea etching ha e ntse e fokotsa tšenyo ea etching ka ho laola phallo ea ion le matla a ion bombardment ka phepelo ea motlakase ea kantle ea RF kapa microwave le phepelo ea matla a RF a leeme holim'a substrate.

Ts'ebetso e omileng ea etching e tjena: khase ea etching e kenngoa ka kamoreng ea ho itšoara ka vacuum, 'me ka mor'a hore khatello ea kamoreng ea karabelo e tsitsa, plasma e hlahisoa ke ho tsoa ha khanya ea seea-le-moea; ka mor'a ho angoa ke li-elektronike tse lebelo le phahameng, e senyeha ho hlahisa li-radicals tsa mahala, tse hasanang holim'a substrate 'me li adsorbed. Tlas'a ketso ea bomo ea ion, li-radicals tsa mahala tse adsorbed li sebetsana le liathomo kapa limolek'hule tse holim'a substrate ho etsa lihlahisoa tsa gaseous, tse ntšoang ka kamoreng ea karabelo. Mokhoa ona o bontšoa setšoantšong se latelang:

Ts'ebetso e omileng ea etching e ka aroloa ka mekhahlelo e mene e latelang:

(1)Ho hlatsa ka mmele: Haholo-holo e itšetlehile ka li-ion tse matla tse ka har'a plasma ho bomola bokaholimo ba thepa e kentsoeng. Palo ea liathomo tse sputtered e itšetlehile ka matla le angle ea likaroloana tsa ketsahalo. Ha matla le angle li lula li sa fetohe, sekhahla sa sputtering sa lisebelisoa tse fapaneng hangata se fapana ka makhetlo a 2 ho isa ho a 3, kahoo ha ho na khetho. Ts'ebetso ea karabelo ke haholo-holo anisotropic.

(2)Etching ea lik'hemik'hale: Plasma e fana ka liathomo le limolek'hule tsa khase, tse sebetsanang le lik'hemik'hale ka holim'a thepa ho hlahisa likhase tse fetohang. Karabelo ena ea lik'hemik'hale e na le khetho e ntle mme e bonts'a litšobotsi tsa isotropic ntle le ho nahana ka sebopeho sa lerata.

Ka mohlala: Si (e tiileng) + 4F → SiF4 (gaseous), photoresist + O (gaseous) → CO2 (gaseous) + H2O (gaseous)

(3)Etching e tsamaisoang ke Ion: Li-ion ke likaroloana tse bakang etching le likaroloana tse tsamaisang matla. Bokhoni bo matla ba likaroloana tse joalo tse tsamaisang matla bo phahame ka mokhoa o fetang o le mong ho feta oa mokhoa o bonolo oa 'mele kapa oa lik'hemik'hale. Har'a tsona, ts'ebetso ea ts'ebetso ea likarolo tsa 'mele le tsa lik'hemik'hale tsa ts'ebetso ke motheo oa ho laola ts'ebetso ea etching.

(4)Etching e kopantsoeng ea ion-barrier: Haholo-holo e bua ka tlhahiso ea lera la tšireletso la polymer ka likaroloana tse kopaneng nakong ea ts'ebetso ea etching. Plasma e hloka lera le joalo le sireletsang ho thibela karabelo e ts'oanang ea mabota a mahlakoreng nakong ea ts'ebetso ea etching. Ka mohlala, ho kenyelletsa C ho Cl le Cl2 etching ho ka hlahisa lera la motsoako oa chlorocarbon nakong ea etching ho sireletsa mabota a mahlakoreng hore a se ke a kenngoa.

2.2.1 Ho hloekisa ka ho omisa

Ho hloekisa ka ho omisa haholo-holo ho bolela ho hloekisa plasma. Li-ion tse ka har'a plasma li sebelisetsoa ho bomola bokaholimo hore bo hloekisoe, 'me liathomo le limolek'hule tse sebakeng se kentsoeng li sebelisana le bokaholimo ho hloekisoa, e le ho tlosa le molora oa photoresist. Ho fapana le etching e omeletseng, mekhahlelo ea ts'ebetso ea ho hloekisa ka mokhoa o omileng hangata ha e kenyelle khetho ea tataiso, kahoo moralo oa ts'ebetso o batla o le bonolo. Lits'ebetsong tse kholo tsa tlhahiso, likhase tse thehiloeng ho fluorine, oksijene kapa hydrogen li sebelisoa haholo e le 'mele o ka sehloohong oa plasma ea karabelo. Ntle le moo, ho eketsa palo e itseng ea argon plasma ho ka ntlafatsa phello ea bombardment ea ion, ka hona ho ntlafatsa ts'ebetso ea ho hloekisa.

Ts'ebetsong ea ho hloekisa ka plasma, mokhoa oa plasma o hole o sebelisoa hangata. Sena ke hobane ts'ebetsong ea ho hloekisa, ho tšeptjoa ho fokotsa phello ea bombardment ea li-ion ho plasma ho laola tšenyo e bakiloeng ke ho phatloha ha ion; mme karabelo e ntlafalitsoeng ea li-radicals tsa mahala tsa lik'hemik'hale e ka ntlafatsa ts'ebetso ea ho hloekisa. Plasma e hole e ka sebelisa li-microwave ho hlahisa plasma e tsitsitseng le e phahameng haholo kantle ho kamore ea karabelo, e hlahisang palo e kholo ea li-radicals tsa mahala tse kenang ka phaposing ea karabelo ho fihlela karabelo e hlokahalang bakeng sa ho hloekisa. Boholo ba mehloli ea khase ea ho hloekisa e omileng indastering e sebelisa likhase tse thehiloeng ho fluorine, tse kang NF3, 'me ho feta 99% ea NF3 e senyeha ka plasma ea microwave. Hoo e ka bang ha ho na phello ea ion bombardment ts'ebetsong ea ho hloekisa, ka hona ho molemo ho sireletsa sephaphatha sa silicon hore se se ke sa senyeha le ho lelefatsa bophelo ba kamore ea karabelo.

Lisebelisoa tse tharo tse metsi tsa ho roala le ho hloekisa

3.1 Mochini oa ho hloekisa oafer oa mofuta oa tanka

Mochini oa ho hloekisa oafer oa mofuta oa sejana o entsoe haholo ka mochini oa phetisetso ea liphaephe tse bulehileng ka pele, mochini oa phetisetso ea ho roala / ho laolla, mochini oa ho kenya moea o tsoang, mochini oa tanka ea mokelikeli oa lik'hemik'hale, mojule oa tanka ea metsi a deionized, tanka ea ho omisa. mojule le mojule oa taolo. E ka hloekisa mabokose a mangata a li-wafers ka nako e le 'ngoe' me e ka finyella li-wafers tse omeletseng le tse omeletseng.

3.2 Trench Wafer Etcher

3.3 Thepa e le 'ngoe ea Wafer Wet Processing Equipment

Ho ea ka merero e fapaneng ea ts'ebetso, lisebelisoa tse le 'ngoe tsa wafer wet process li ka aroloa ka mekhahlelo e meraro. Sehlopha sa pele ke lisebelisoa tsa ho hloekisa liphaephe tse le 'ngoe, tseo lipakane tsa tsona tsa ho hloekisa li kenyelletsa likaroloana, lintho tse phelang, lera la oxide ea tlhaho, litšila tsa tšepe le lintho tse ling tse silafatsang; sehlopha sa bobeli ke lisebelisoa tsa ho hlatsuoa tse nang le liphaephe tse le 'ngoe, tseo morero oa tsona o ka sehloohong oa ts'ebetso e leng ho tlosa likaroloana tse holim'a sephaphatha; sehlopha sa boraro ke thepa e le 'ngoe ea li-wafer etching, e sebelisoang haholo ho tlosa lifilimi tse tšesaane. Ho ea ka merero e fapaneng ea ts'ebetso, lisebelisoa tse lenngoeng tsa "wafer etching" li ka aroloa ka mefuta e 'meli. Mofuta oa pele ke lisebelisoa tse bonolo tsa etching, tse sebelisoang haholo-holo ho tlosa likarolo tsa tšenyo ea filimi e bakoang ke ho kenngoa ha ion e matla; mofuta oa bobeli ke sehlabelo lera ho tloswa thepa, e haholo-holo sebelisoa ho tlosa lera le mokoallo ka mor'a hore lephaka thinning kapa lik'hemik'hale mechanical polishing.

Ho ea ka pono ea meralo ea mochini ka kakaretso, meralo ea mantlha ea mefuta eohle ea lisebelisoa tsa mochini o nang le sephaephe se le seng se ts'oana, ka kakaretso se na le likarolo tse tšeletseng: foreimi e kholo, sistimi ea phetisetso ea wafer, mojule oa kamore, phepelo ea mokelikeli oa lik'hemik'hale le mochini oa phetisetso, sistimi ea software. le mojule oa taolo ea elektroniki.

3.4 Thepa e le 'Ngoe ea ho Hloekisa Wafer

Thepa e le 'ngoe ea ho hloekisa e entsoe ho latela mokhoa oa setso oa ho hloekisa oa RCA,' me morero oa eona ke ho hloekisa likaroloana, lintho tse phelang, lera la oxide ea tlhaho, litšila tsa tšepe le litšila tse ling. Mabapi le ts'ebetso ea ts'ebetso, lisebelisoa tsa ho hloekisa liphaephe tse le 'ngoe hajoale li sebelisoa haholo lits'ebetsong tse ka pele le tsa morao-rao tsa tlhahiso ea potoloho e kopaneng, ho kenyelletsa ho hloekisa pele le ka morao ho etsoa filimi, ho hloekisa ka mor'a ho kenngoa ha plasma, ho hloekisa ka mor'a ho kenngoa ha ion, ho hloekisa ka mor'a lik'hemik'hale. ho bentša ka mochini, le ho hloekisa ka mor'a ho beha tšepe. Ntle le ts'ebetso e phahameng ea mocheso oa phosphoric acid, lisebelisoa tsa ho hloekisa li-wafer tse le 'ngoe li lumellana hantle le mekhoa eohle ea ho hloekisa.

3.5 Thepa e le 'ngoe ea Wafer Etching

Morero oa ts'ebetso ea lisebelisoa tsa ho cheka liphaephe tse le 'ngoe ke haholo-holo tse tšesaane tsa ho etsa filimi. Ho ea ka morero oa ts'ebetso, e ka aroloa ka mekhahlelo e 'meli, e leng, lisebelisoa tse khanyang (tse sebelisoang ho tlosa lera la tšenyo ea filimi e bakoang ke ho kenngoa ha ion ea matla a phahameng) le thepa ea ho tlosa lera ea sehlabelo (e sebelisetsoang ho tlosa lera la mokoallo ka mor'a sekoti. ho bentša kapa ho bentša ka mokhoa oa lik'hemik'hale). Lisebelisoa tse hlokang ho tlosoa ts'ebetsong ka kakaretso li kenyelletsa silicon, silicon oxide, silicon nitride le likarolo tsa filimi ea tšepe.

Lisebelisoa tse 'nè tse ommeng tsa ho khabisa le ho hloekisa

4.1 Ho hlophisoa ha lisebelisoa tsa plasma etching

Ntle le lisebelisoa tsa ion sputtering etching tse haufi le karabelo e hlakileng ea 'mele le lisebelisoa tsa degumming tse haufi le karabelo e hloekileng ea lik'hemik'hale, etching ea plasma e ka aroloa ka mekhahlelo e' meli ho latela mahlale a fapaneng a tlhahiso ea plasma le taolo:

-CCP (Capacitively Coupled Plasma);

- Etching ea Plasma e Kopantsoeng ka Inductively (ICP).

4.1.1 CCP

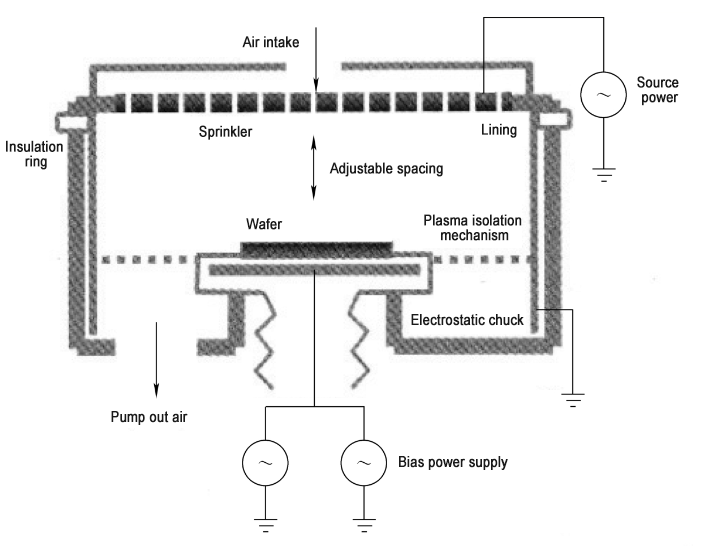

Etching ea plasma e kopantsoeng ka matla ke ho hokela phepelo ea matla a maqhubu a seea-le-moea ho e 'ngoe kapa tse peli tsa li-electrode tse holimo le tse tlase ka phaposing ea karabelo, 'me plasma e lipakeng tsa lipoleiti tsena tse peli e etsa capacitor ka potoloho e tšoanang e nolofalitsoeng.

Ho na le mekhoa e 'meli ea pele ea theknoloji e joalo:

E 'ngoe ke etching ea pele ea plasma, e hokahanyang phepelo ea motlakase ea RF ho eleketrode e kaholimo le eleketrode e tlase moo sephaphatha se behiloeng teng. Hobane plasma e hlahisoang ka tsela ena e ke ke ea theha sheath e lekaneng ea ion holim'a sephaphatha, matla a ion bombardment a tlase, 'me hangata a sebelisoa lits'ebetsong tse kang silicon etching e sebelisang likaroloana tse sebetsang e le eona ntho e ka sehloohong.

E 'ngoe ke "reactive ion etching" (RIE) ea pele, e hokahanyang phepelo ea motlakase ea RF le eleketrode e tlase moo sephaphatha se leng teng, 'me e thea eleketrode e kaholimo e nang le sebaka se seholoanyane. Theknoloji ena e ka theha sheath e teteaneng ea ion, e loketseng lits'ebetso tsa etching tsa dielectric tse hlokang matla a ion a phahameng ho kenya letsoho karabelong. Motheong oa "ion etching" ea pele, "DC magnetic field perpendicular" ho lebaleng la motlakase la RF e eketsoa ho theha ExB drift, e ka eketsang monyetla oa ho thulana ha lielektrone le likaroloana tsa khase, ka hona ho ntlafatsa ka nepo mahloriso a plasma le sekhahla sa etching. Etching ena e bitsoa magnetic field enhanced reactive ion etching (MERIE).

Litheknoloji tse tharo tse ka holimo li na le bothata bo tloaelehileng, ke hore, mahloriso a plasma le matla a eona a ke ke a laoloa ka thoko. Mohlala, molemong oa ho eketsa sekhahla sa etching, mokhoa oa ho eketsa matla a RF o ka sebelisoa ho eketsa mahloriso a plasma, empa matla a RF a ntseng a eketseha a tla lebisa keketseho ea matla a ion, a tla baka tšenyo ho lisebelisoa tse sebetsang. sephaphatha. Lilemong tse leshome tse fetileng, theknoloji ea capacitive coupling e amohetse moralo oa mehloli e mengata ea RF, e hokahaneng le li-electrode tse holimo le tse tlase ka ho latellana kapa ka bobeli ho li-electrode tse tlase.

Ka ho khetha le ho bapisa maqhubu a fapaneng a RF, sebaka sa li-electrode, sebaka, lisebelisoa le likarolo tse ling tsa bohlokoa li hokahanngoa hammoho, mahloriso a plasma le matla a ion a ka aroloa ka hohle kamoo ho ka khonehang.

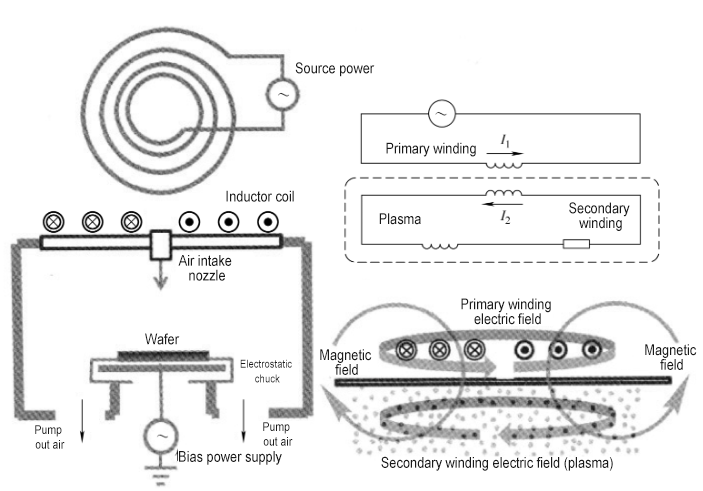

4.1.2 ICP

Etching ea plasma e kopantsoeng ka mokhoa o ts'oarehang ke ho beha sete e le 'ngoe kapa ho feta tsa likhoele tse hoketsoeng motlakaseng oa maqhubu a seea-le-moea ho potoloha kapa ho potoloha phaposi ea karabelo. Matla a khoheli a fapanyetsanang a hlahisoang ke maqhubu a seea-le-moea sekoeleng a kena ka kamoreng ea karabelo ka fensetere ea dielectric ho potlakisa lielektrone, ka hona ho hlahisa plasma. Sepotolohong se tšoanang le se nolofalitsoeng (transformer), khoele ke mokelikeli oa mantlha oa matsoeli, 'me plasma ke inductance ea bobeli ea matsoeli.

Mokhoa ona oa ho kopanya o ka finyella motsoako oa plasma o fetang taelo e le 'ngoe ea boholo bo phahameng ho feta capacitive coupling ka khatello e tlaase. Ntle le moo, phepelo ea motlakase ea bobeli ea RF e hokahane le sebaka sa sephaphatha e le phepelo ea matla a leeme ho fana ka matla a ion bombardment. Ka hona, mahloriso a ion a ipapisitse le matla a mohloli oa coil mme matla a ion a ipapisitse le phepelo ea matla a leeme, ka hona a fihlella ho hlakoloa ka botlalo ha mahloriso le matla.

4.2 Thepa ea Plasma Etching

Hoo e ka bang li-etchants tsohle tse ka har'a etching e omileng li hlahisoa ka kotloloho kapa ka mokhoa o sa tobang ho tsoa ho plasma, kahoo ho omella ho omileng hangata ho bitsoa plasma etching. Plasma etching ke mofuta oa plasma etching ka kutloisiso e pharaletseng. Meralong e 'meli ea pele ea lipolanete tse sephara, e 'ngoe ke ea ho sila poleiti moo sephaphatha se leng teng 'me poleiti e 'ngoe e hokahane le mohloli oa RF; e ’ngoe ke e fapaneng. Moqaping oa pele, sebaka sa poleiti e thehiloeng hangata se seholo ho feta sebaka sa poleiti e hokahaneng le mohloli oa RF, 'me khatello ea khase ka har'a reactor e phahame. Sekhahla sa ion se entsoeng holim'a sephaphatha se tšesaane haholo, 'me sephaphatha se bonahala se "qoelitsoe" ka har'a plasma. Etching e phethoa haholo-holo ke karabelo ea lik'hemik'hale pakeng tsa likaroloana tse sebetsang ka har'a plasma le bokaholimo ba thepa e kentsoeng. Matla a ion bombardment a nyane haholo, mme ho nka karolo ha ona ho etching ho tlase haholo. Moetso ona o bitsoa "plasma etching mode". Moqaping o mong, hobane tekanyo ea ho nka karolo ha ion bombardment e batla e le kholo, e bitsoa reactive ion etching mode.

4.3 Thepa ea Reactive Ion Etching

Reactive ion etching (RIE) e bolela ts'ebetso ea etching eo ho eona likaroloana tse sebetsang le li-ion tse qositsoeng li nkang karolo ts'ebetsong ka nako e le 'ngoe. Har'a tsona, likaroloana tse sebetsang haholo ke likaroloana tse sa nke lehlakore (tse tsejoang hape e le li-radicals tsa mahala), tse nang le khatello e phahameng (hoo e ka bang 1% ho ea ho 10% ea khase ea khase), e leng likarolo tse ka sehloohong tsa etchant. Lihlahisoa tse hlahisoang ke karabelo ea lik'hemik'hale pakeng tsa tsona le thepa e entsoeng li ka 'na tsa senyeha' me tsa ntšoa ka ho toba ka kamoreng ea karabelo, kapa li bokelloa holim'a metsi; ha li-ion tse qosoang li le boemong bo tlaase (10-4 ho 10-3 ea mahloriso a khase), 'me li potlakisoa ke tšimo ea motlakase ea sheath ea ion e entsoeng ka holim'a sephaphatha ho phatloha holim'a metsi. Ho na le mesebetsi e 'meli e meholo ea likaroloana tse qosoang. E 'ngoe ke ho senya sebopeho sa athomo sa thepa e entsoeng, ka hona ho potlakisa lebelo leo likaroloana tse sebetsang li itšoarang ka lona; e 'ngoe ke ho bomola le ho tlosa lihlahisoa tsa karabelo tse bokelitsoeng e le hore thepa e entsoeng e kopane ka ho feletseng le likaroloana tse sebetsang, e le hore etching e tsoele pele.

Hobane li-ion ha li kenye letsoho ka kotloloho tšebetsong ea etching (kapa li ikarabella bakeng sa karolo e nyane haholo, joalo ka ho tlosoa ha libomo tsa 'mele le ho kenella ka kotloloho hoa lik'hemik'hale tsa li-ion tse sebetsang), ha re bua hantle, ts'ebetso e kaholimo ea etching e lokela ho bitsoa etching ea ion-assisted. Lebitso reactive ion etching ha le nepahale, empa le ntse le sebelisoa le kajeno. Thepa ea khale ea RIE e ile ea sebelisoa ka bo-1980. Ka lebaka la ts'ebeliso ea motlakase oa RF e le 'ngoe le moralo o bonolo oa kamore ea karabelo, e na le meeli mabapi le sekhahla sa etching, ho ts'oana le khetho.

4.4 Tšimo ea Magnetic e Matlafalitsoeng ea Ion Etching e Matlafatsoa

Sesebelisoa sa MERIE (Magnetically Enhanced Reactive Ion Etching) ke sesebelisoa sa etching se hahiloeng ka ho kenyelletsa matla a khoheli a DC ho sesebelisoa sa RIE se sephara 'me se reretsoe ho eketsa sekhahla sa etching.

Thepa ea MERIE e ile ea sebelisoa ka bongata bo boholo lilemong tsa bo-1990, ha thepa ea ho eta e le 'ngoe e se e fetohile thepa e ka sehloohong indastering. Phoso e kholo ka ho fetisisa ea lisebelisoa tsa MERIE ke hore kabo ea sebaka sa inhomogeneity ea mahloriso a plasma e bakoang ke matla a khoheli e tla lebisa ho phapano ea hajoale kapa ea motlakase sesebelisoa se kopaneng sa potoloho, ka hona se baka tšenyo ea sesebelisoa. Kaha tšenyo ena e bakoa ke ho inhomogeneity hang-hang, ho potoloha ha matla a khoheli ho ke ke ha e felisa. Ha boholo ba li-circuits tse kopantsoeng li ntse li fokotseha, ts'enyehelo ea lisebelisoa tsa bona e ntse e tsoela pele ho ameha ho plasma inhomogeneity, 'me theknoloji ea ho eketsa sekhahla sa etching ka ho ntlafatsa matla a khoheli e ile ea nkeloa sebaka ke theknoloji e mengata ea RF e sebetsang ka matla a ion etching. ke, theknoloji e kopantsoeng ka katleho ea plasma etching.

4.5 Sesebelisoa se kopantsoeng hantle sa plasma

Thepa ea capacitively coupled plasma (CCP) ke sesebelisoa se hlahisang plasma ka phaposing ea karabelo ka capacitive coupling ka ho sebelisa motlakase oa radio frequency (kapa DC) ho poleiti ea elektrode mme e sebelisetsoa ho etching. Molao-motheo oa eona oa etching o tšoana le oa lisebelisoa tse sebetsang tsa ion etching.

Setšoantšo se nolofalitsoeng sa moralo oa lisebelisoa tsa CCP se bontšitsoe ka tlase. Ka kakaretso e sebelisa mehloli e 'meli kapa e meraro ea RF ea maqhubu a fapaneng, 'me e meng e sebelisa lisebelisoa tsa motlakase tsa DC. Maqhubu a phepelo ea matla a RF ke 800kHz ~ 162MHz, mme tse sebelisoang hangata ke 2MHz, 4MHz, 13MHz, 27MHz, 40MHz le 60MHz. Lisebelisoa tsa motlakase tsa RF tse nang le maqhubu a 2MHz kapa 4MHz hangata li bitsoa mehloli e tlase ea maqhubu a RF. Ka kakaretso li hokahane le eleketrode e tlase moo sephaphatha se leng teng. Li sebetsa hantle ho laola matla a ion, kahoo li boetse li bitsoa lisebelisoa tsa matla a bias; Lisebelisoa tsa motlakase tsa RF tse nang le maqhubu a ka holimo ho 27MHz li bitsoa mehloli ea RF e phahameng-frequency. Li ka kopanngoa le electrode e ka holimo kapa electrode e ka tlaase. Li sebetsa hantle haholo ho laola khatello ea mali ea plasma, kahoo li boetse li bitsoa mohloli oa matla a mohloli. Motlakase oa 13MHz RF o bohareng 'me ka kakaretso o nkoa e na le likarolo tse peli tse ka holimo empa a batla a fokola. Hlokomela hore le hoja mahloriso le matla a plasma a ka fetoloa ka har'a mefuta e itseng ka matla a mehloli ea RF ea maqhubu a fapaneng (seo ho thoeng ke phello ea ho kopanya), ka lebaka la litšobotsi tsa capacitive coupling, li ke ke tsa fetoloa le ho laoloa ka ho feletseng.

Kabo ea matla ea li-ion e na le phello e kholo ts'ebetsong e qaqileng ea ts'ebetso ea etching le ts'enyo ea lisebelisoa, ka hona, nts'etsopele ea theknoloji ea ho ntlafatsa kabo ea matla a ion e fetohile e 'ngoe ea lintlha tsa bohlokoa tsa lisebelisoa tse tsoetseng pele tsa ho eta. Hajoale, mahlale a sebelisitsoeng ka katleho tlhahisong a kenyelletsa drive e nyalisitsoeng ea RF e mengata, DC superposition, RF e kopantsoeng le DC pulse bias, le synchronous pulsed RF tlhahiso ea phepelo ea matla a leeme le phepelo ea motlakase ea mohloli.

Thepa ea etching ea CCP ke e 'ngoe ea mefuta e' meli e sebelisoang haholo ea lisebelisoa tsa plasma etching. E sebelisoa haholo ts'ebetsong ea lisebelisoa tsa dielectric, joalo ka lebota la heke le maske a thata sebakeng se ka pele sa logic chip process, etching ea lesoba le bohareng, mosaic le aluminium pad pad sethaleng se ka morao, hammoho le. ho kenngoa ha liforo tse tebileng, masoba a tebileng le masoba a ho kopanya lithapo ka har'a 3D flash memory chip process (ho nka mohlala oa silicon nitride / silicon oxide).

Ho na le liphephetso tse peli tse kholo le litsela tsa ntlafatso tse tobaneng le lisebelisoa tsa CCP etching. Taba ea pele, ts'ebelisong ea matla a ion a phahameng haholo, bokhoni ba ho hokahana ba likarolo tse phahameng tsa karo-karolelano (joalo ka lesoba le groove etching ea 3D flash memory e hloka karo-karolelano e fetang 50:1). Mokhoa oa hajoale oa ho eketsa matla a leeme ho eketsa matla a ion o sebelisitse matla a RF a fihlang ho li-watts tse 10,000. Ka lebaka la mocheso o mongata o hlahisoang, thekenoloji ea ho pholisa le ho laola mocheso oa kamore ea karabelo e hloka ho ntlafatsoa ka ho tsoelang pele. Taba ea bobeli, ho hlokahala hore ho be le khatelo-pele ho nts'etsopele ea likhase tse ncha tsa etching ho rarolla bothata ba bokhoni ba etching.

4.6 Lisebelisoa tsa Plasma Etching ka Inductively Coupled

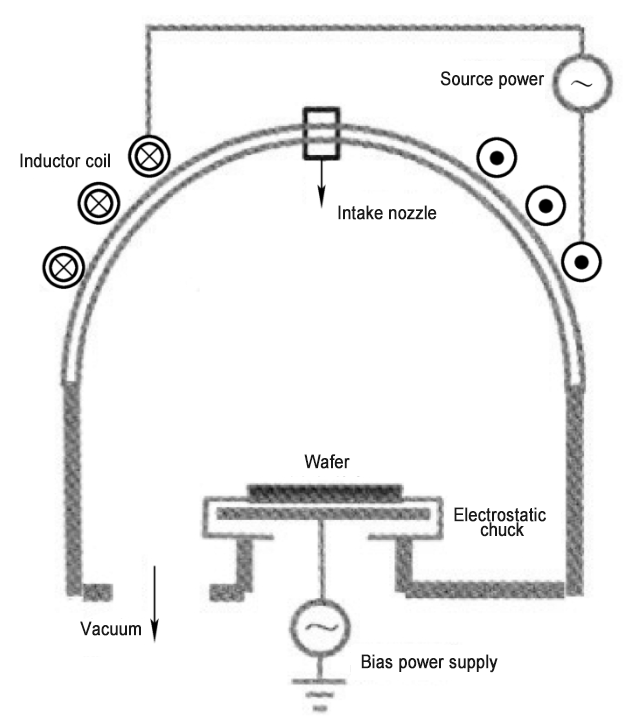

Thepa ea etching e kopantsoeng ea plasma (ICP) ke sesebelisoa se kopanyang matla a mohloli oa matla a maqhubu a seea-le-moea sebakeng sa karabelo ka sebopeho sa matla a khoheli ka khoele ea inductor, ka hona se hlahisa plasma bakeng sa etching. Molao-motheo oa eona oa etching o boetse ke oa kakaretso e tloaelehileng ea ion etching.

Ho na le mefuta e 'meli ea mantlha ea meralo ea mohloli oa plasma bakeng sa lisebelisoa tsa etching tsa ICP. E 'ngoe ke theknoloji e kopantsoeng ea plasma (TCP) e entsoeng le e hlahisoang ke Lam Research. Coil ea eona ea inductor e behiloe sefofaneng sa fensetere sa dielectric ka holim'a kamore ea karabelo. Letšoao la 13.56MHz RF le hlahisa matla a khoheli a chenchana ka har'a khoele e shebaneng le fensetere ea dielectric 'me e fapanyetsana ka mokhoa o hlakileng le axis ea coil joalo ka setsi.

Matla a khoheli a kena ka phaposing ea karabelo ka fensetere ea dielectric, 'me matla a khoheli a fapanyetsanang a hlahisa sebaka se fapaneng sa motlakase se bapileng le fensetere ea dielectric ka phaposing ea karabelo, ka tsela eo e fihlella karohano ea khase ea etching le ho hlahisa plasma. Kaha molao-motheo ona o ka utloisisoa e le sefetoleli se nang le khoele ea inductor e le sebaka sa mantlha sa moea le plasma e ka kamoreng ea karabelo e le matsoelintsoeke a bobeli, etching ea ICP e rehelletsoe ka sena.

Monyetla o ka sehloohong oa theknoloji ea TCP ke hore sebopeho se bonolo ho se phahamisa. Ka mohlala, ho tloha ho 200mm wafer ho ea 300mm wafer, TCP e ka boloka phello e tšoanang ea etching ka ho eketsa boholo ba khoele.

Moralo o mong oa mohloli oa lero la lero la mali ke theknoloji ea decoupled plasma source (DPS) e entsoeng le ho hlahisoa ke Applied Materials, Inc. ea United States. Coil ea eona ea inductor e na le leqeba la mahlakore a mararo fensetereng ea hemispherical dielectric. Molao-motheo oa ho hlahisa plasma o tšoana le theknoloji e boletsoeng ka holimo ea TCP, empa katleho ea khase ea khase e batla e phahame, e leng se loketseng ho fumana khatello e phahameng ea plasma.

Kaha katleho ea coupling inductive ho hlahisa plasma e phahame ho feta ea capacitive coupling, 'me plasma e hlahisoa haholo sebakeng se haufi le fensetere ea dielectric, mahloriso a eona a plasma a khethoa ke matla a mohloli oa matla a matla a hokahaneng le inductor. coil, 'me matla a ion a ka har'a sheath ea ion e holim'a sephaphatha ha e le hantle a khethoa ke matla a phepelo ea matla a leeme, kahoo mahloriso le matla a li-ion. e ka laoloa ka boikemelo, ka tsela eo ea fihlela ho arohana.

Thepa ea etching ea ICP ke e 'ngoe ea mefuta e' meli e sebelisoang haholo ea lisebelisoa tsa plasma etching. E sebelisoa haholo bakeng sa ho chesoa ha lithapo tse sa tebang tsa silicon, germanium (Ge), meaho ea heke ea polysilicon, meaho ea liheke tsa tšepe, silicon e senyehileng (Strained-Si), lithapo tsa tšepe, lipampiri tsa tšepe (Pads), limaske tse thata tsa mosaic le lits'ebetso tse ngata ho theknoloji e mengata ea litšoantšo.

Ho phaella moo, ka ho phahama ha li-circuits tse kopantsoeng ka mahlakoreng a mararo, li-sensor tsa setšoantšo sa CMOS le lisebelisoa tse nyenyane tsa motlakase (MEMS), hammoho le keketseho e potlakileng ea ts'ebeliso ea lisebelisoa tsa silicon vias (TSV), masoba a boholo bo boholo ba oblique le. Etching e tebileng ea silicon e nang le morphologies e fapaneng, bahlahisi ba bangata ba hlahisitse lisebelisoa tsa ho etching tse ntlafalitsoeng ka ho khetheha bakeng sa lits'ebetso tsena. Litšobotsi tsa eona ke botebo bo boholo ba etching (mashome kapa esita le makholo a li-micron), kahoo e sebetsa haholo tlas'a phallo e phahameng ea khase, khatello e phahameng le maemo a matla a phahameng.

—————————————————————————————————————————————————— ————————————-

Semicera e ka fana kalikarolo tsa graphite, bonolo/bothata bo utloang, likarolo tsa silicon carbide, CVD silicon carbide likarolo, leLikarolo tse koahetsoeng ke SiC/TaCka matsatsi a 30.

Haeba u thahasella lihlahisoa tse ka holimo tsa semiconductor,ka kopo o seke oa tsilatsila ho ikopanya le rona ka lekhetlo la pele.

Mohala: +86-13373889683

Whatsapp: +86-15957878134

Email: sales01@semi-cera.com

Nako ea poso: Aug-31-2024