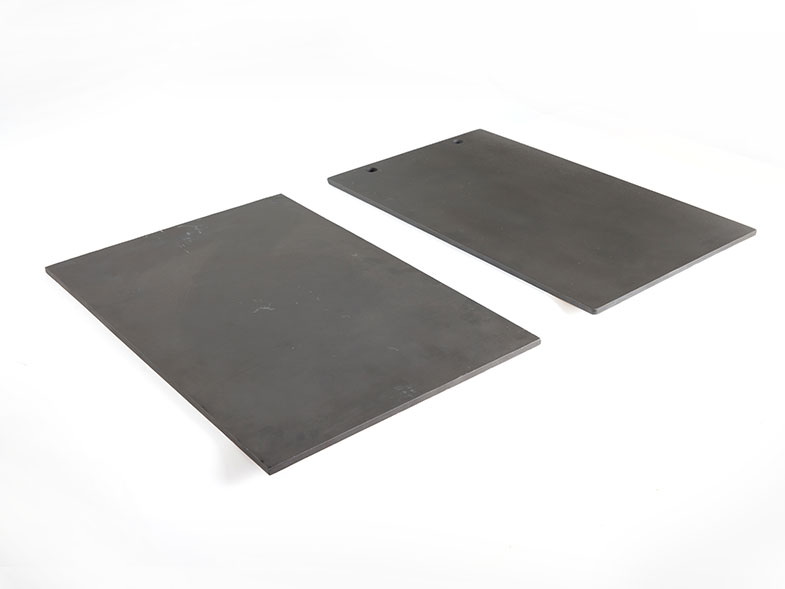

Silicon carbide sebōpi tubee na le melemo ea matla a phahameng, boima bo phahameng, khanyetso e ntle ea ho apara, ho hanyetsa mocheso o phahameng, ho hanyetsa kutu, ho hanyetsa mocheso o motle oa mocheso, mocheso o phahameng oa mocheso, khanyetso e ntle ea oxidation joalo-joalo. Haholo-holo e sebelisoa ho lahla maqhubu a mahareng, sebopi se fapaneng sa kalafo ea mocheso, metallurgy, indasteri ea lik'hemik'hale, tšepe e se nang ferrous le mesebetsi e meng.Silicon carbide sebōpi tubee sebelisoa haholo sebōping sa metallurgical sintering le sebōpi sa ho futhumatsa maqhubu a mahareng, 'me bolelele ba eona bo ka etsoa ho latela litlhoko tsa sebele tsa sebaka seo.

Litšobotsi tsali-tubes tsa silicon carbide sebōpi

Silicon carbide furnace tube ke sehlahisoa se setle ka ho fetisisa sa silicon carbide se kentsoeng ka mocheso o phahameng ka silicon carbide e le thepa e tala ea mantlha. E na le melemo ea ho hanyetsa mocheso o phahameng, ho hanyetsa kutu, ho potlaka ha mocheso oa mocheso, matla a phahameng, boima bo phahameng, ho hanyetsa ho apara hantle, ho hanyetsa mocheso o motle oa mocheso, mocheso o moholo oa mocheso, ho hanyetsa oxidation e ntle joalo-joalo. Lipheletso tsena ka bobeli li na le lihlahla tse khethehileng tse nang le mocheso o phahameng oa mocheso, ho bola ha tharollo ea tšepe ho lisebelisoa tsa motlakase (ho kenyeletsoa molamu oa silicon carbide, terata ea sebōpi sa motlakase, joalo-joalo) ho ka qojoa ka katleho, 'me matšoao a molemo ho feta mefuta eohle ea lihlahisoa tsa graphite. . The silicon carbide furnace tube e na le conductivity ea mocheso, ho hanyetsa oxidation, ho hanyetsa mocheso oa mocheso, ho hanyetsa mocheso o phahameng, botsitso bo botle ba lik'hemik'hale, ho hanyetsa acid e matla, ha ho na karabelo ho acid e matla le alkali.

Silicon carbide sebōpi tubetheknoloji ea tlhahiso: sehlahisoa se phethiloeng se nka silicon carbide e le thepa e ka sehloohong e tala, 'me ke sehlahisoa se setle sa silicon carbide se phethiloeng ka theknoloji e khethehileng mocheso o phahameng. Tekanyetso ea bolelele e ka etsoa ho latela litlhoko tsa 'nete tsa bareki. Tšebeliso e ka sehloohong ea silicon carbide sebōpi: e sebelisoa haholo koetlisong ea tšepe e se nang ferrous, lihlahisoa tsa aluminium tsa degasing system, mechine ea khatiso le ea ho daea, koetliso ea zinki le aluminium le ho qeta ho sebetsa lihlahisoa.

Ntlafatso ea indasteri ea silicon carbide

Silicon carbide e na le litšoaneleho tsa "impedance" e phahameng, lerata le tlase, linearity e ntle, joalo-joalo, ke e 'ngoe ea lisebelisoa tse ntseng li hola ka potlako tsa silicon carbide,' me ke ea pele ea ho fihlela khoebo. Ha ho bapisoa le li-MOSFETs, ha ho na mathata a ts'epahalo a bakoang ke mefokolo ea heke ea oxide le mefokolo e tlase ea ho tsamaea, 'me litšobotsi tsa eona tsa ts'ebetso ea unipolar li boloka ts'ebetso e ntle ea maqhubu a holimo. Ho feta moo, sebopeho sa silicon carbide junction se na le botsitso bo betere le ho ts'epahala ha mocheso o phahameng hoo motlakase oa monyako o atisang ho ba mpe, ke hore, sesebelisoa se bulehileng, se sa rateheng haholo bakeng sa lits'ebetso tsa motlakase oa motlakase, 'me ha se lumellane le se tloaelehileng hona joale. khanna potoloho. Ka ho hlahisa theknoloji ea sesebelisoa sa groove injection, sesebelisoa se ntlafetseng tlas'a boemo bo tloaelehileng sea ntlafatsoa. Leha ho le joalo, lisebelisoa tse ntlafetseng li atisa ho thehoa ka litšenyehelo tsa litšoaneleho tse ling tse ntle tsa ho hanyetsa, kahoo hangata ho buloa (mofuta oa ho fokotseha) ho bonolo ho finyella matla a phahameng a matla le matla a hona joale, 'me mofuta oa ho fokotseha o ka finyelloa ka ho phalla ka tloaelo ho tloha boemong ba ho sebetsa. Mokhoa oa cascade o kengoa ts'ebetsong ka letoto la li-MOSFET tse thehiloeng ho silicon-voltage tse tlase. The cascaded drive circuit ka tlhaho e lumellana le sepheo se akaretsang sa silicon device drive circuit. Sebopeho sena sa cascade se loketse haholo bakeng sa ho nkela silicon ea pele sebaka sa maemo a phahameng a matla le a matla, 'me ka ho toba e qoba bothata ba ho lumellana ha potoloho ea koloi.

Nako ea poso: Sep-25-2023