Silicon nitride (Si₃N₄) ceramics, joalo ka lirafshoa tsa meralo e tsoetseng pele, li na le thepa e ntle joalo ka ho hanyetsa mocheso o phahameng, matla a phahameng, ho tiea ho hoholo, boima bo phahameng, khanyetso ea creep, khanyetso ea oxidation, le ho hanyetsa ho roala. Ntle le moo, li fana ka ts'ebetso e ntle ea ho tsieleha ha mocheso, thepa ea dielectric, conductivity e phahameng ea mocheso, le ts'ebetso e ntle ea phetisetso ea maqhubu a motlakase a phahameng haholo. Mehaho ena e ikhethang e pharaletseng e etsa hore e sebelisoe haholo likarolong tse rarahaneng tsa meralo, haholo-holo sebakeng sa lifofane le libakeng tse ling tsa theknoloji e phahameng.

Leha ho le joalo, Si₃N₄, e le motsoako o nang le li-covalent bond tse matla, o na le mohaho o tsitsitseng o etsang hore ho thatafalloa ke ho tetebela ho ea ho boemo bo phahameng ka ho arohana ha boemo bo tiileng feela. Ho khothaletsa sintering, lithuso tsa sintering, joalo ka tšepe oxides (MgO, CaO, Al₂O₃) le li-oxide tsa lefatše tse sa tloaelehang (Yb₂O₃, Y₂O₃, Lu₂O₃, CeO₂), li eketsoa ho tsamaisa densification ka mochini oa sintering oa mokelikeli.

Hajoale, theknoloji ea lisebelisoa tsa semiconductor ea lefats'e e ntse e tsoela pele ho ea ho li-voltage tse phahameng, maqhubu a maholo, le matla a maholo a matla. Lipatlisiso mabapi le mekhoa ea ho etsa lirafshoa tsa Si₃N₄ li pharalletse. Sengoliloeng sena se hlahisa lits'ebetso tsa sintering tse ntlafatsang ka nepo boima le thepa e felletseng ea lirafshoa tsa silicon nitride.

Mekhoa e Tloaelehileng ea Sintering bakeng sa Si₃N₄ Ceramics

Papiso ea Ts'ebetso ea Si₃N₄ Ceramics e Lokisitsoeng ke Mekhoa e fapaneng ea Sintering

1. Reactive Sintering (RS):Reactive sintering e ne e le mokhoa oa pele o sebelisoang ho lokisa lirafshoa tsa Si₃N₄ indastering. E bonolo, ha e na litšenyehelo, ebile e khona ho etsa libopeho tse rarahaneng. Leha ho le joalo, e na le potoloho e telele ea tlhahiso, e sa lokelang ho hlahisa lihlahisoa tsa indasteri.

2. Pressureless Sintering (PLS):Ena ke mokhoa o bonolo le o bonolo oa sintering. Leha ho le joalo, e hloka lisebelisoa tsa boleng bo holimo tsa Si₃N₄ 'me hangata e fella ka lirafshoa tse nang le sekhahla se tlase, ho fokotseha ho hoholo, le tšekamelo ea ho peperana kapa ho holofala.

3. Hot-Press Sintering (HP):Tšebeliso ea khatello ea mechine e sa tšoaneng e eketsa matla a ho khanna bakeng sa sintering, e leng se lumellang hore li-ceramics tse teteaneng li hlahisoe ka mocheso oa 100-200 ° C ho feta o sebelisoang ho sintering e se nang khatello. Mokhoa ona o sebelisoa hangata bakeng sa ho etsa lirafshoa tse batlang li le bonolo, empa ho thata ho fihlela litlhoko tsa botenya le sebopeho sa thepa ea substrate.

4. Spark Plasma Sintering (SPS):SPS e tšoauoa ka ho chesa ka potlako, ho ntlafatsa lijo-thollo, le ho fokotsa mocheso oa sintering. Leha ho le joalo, SPS e hloka matsete a bohlokoa ho lisebelisoa, 'me ho lokisoa ha li-ceramics tsa Si₃N₄ tse phahameng tsa mocheso ka SPS li ntse li le sethaleng sa liteko' me ha li e-s'o ntlafatsoe.

5. Khatello ea Khatello ea Khase (GPS):Ka ho sebelisa khatello ea khase, mokhoa ona o thibela ho senyeha ha ceramic le ho theola boima ba 'mele ka mocheso o phahameng. Ho bonolo ho hlahisa li-ceramics tse matla haholo 'me li nolofalletsa tlhahiso ea lihlopha. Leha ho le joalo, mohato o le mong oa khatello ea khase ea khase e thata ho hlahisa likarolo tsa sebopeho ka 'mala o tšoanang oa ka hare le oa ka ntle le sebopeho. Ho sebelisa mehato e 'meli kapa mehato e mengata ea sintering ho ka fokotsa haholo litaba tsa oksijene ea intergranular, ho ntlafatsa conductivity ea mocheso, le ho ntlafatsa thepa ka kakaretso.

Leha ho le joalo, mocheso o phahameng oa sintering oa mehato e 'meli ea khatello ea khase e lebisitse lipatlisiso tse fetileng ho tsepamisa maikutlo haholo ho lokisetseng li-substrates tsa ceramic tsa Si₃N₄ tse nang le conductivity e phahameng ea mocheso le matla a ho kobeha ha mocheso oa kamore. Lipatlisiso mabapi le lirafshoa tsa Si₃N₄ tse nang le thepa e felletseng ea mochini le lisebelisoa tsa mochini tse nang le mocheso o phahameng li fokola.

Mokhoa oa Sintering oa Khatello ea Khase e Mehato e 'meli bakeng sa Si₃N₄

Yang Zhou le basebetsi-mmoho ba Chongqing University of Technology ba sebelisitse sistimi ea lithuso ea 5 wt.% Yb₂O₃ + 5 wt.% Al₂O₃ ho lokisa lirafshoa tsa Si₃N₄ ho sebelisa mehato e le 'ngoe le mehato e' meli ea khatello ea khase ea khase ho 1800 ° C. Li-ceramics tsa Si₃N₄ tse hlahisitsoeng ke mohato oa mehato e 'meli ea sintering li ne li e-na le sekhahla se phahameng le thepa e ntle ea mochini. Se latelang se akaretsa litlamorao tsa mehato e le 'ngoe le mehato e' meli ea khatello ea khase ea khase ho microstructure le thepa ea mochini ea likarolo tsa ceramic tsa Si₃N₄.

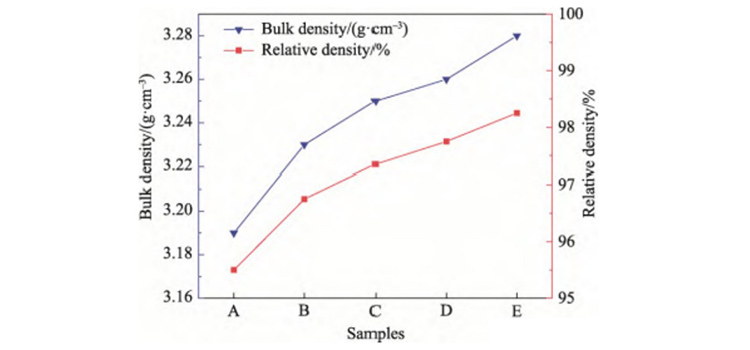

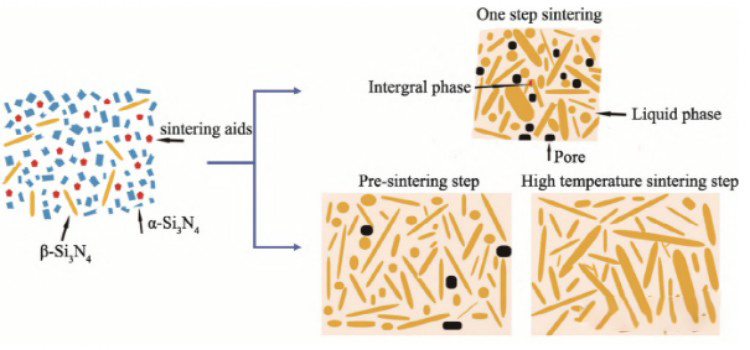

Density Ts'ebetso ea ho teteana ea Si₃N₄ hangata e kenyelletsa methati e meraro, 'me e kopana lipakeng tsa methati. Mokhahlelo oa pele, tlhophiso ea likaroloana, 'me mohato oa bobeli, ho qhibiliha-pula, ke mekhahlelo e bohlokoa ka ho fetisisa ea ho kopanya. Nako e lekaneng ea karabelo methating ena e ntlafatsa haholo boholo ba sampole. Ha mocheso oa pele ho sintering bakeng sa mehato e 'meli ea sintering e behiloe ho 1600 ° C, lithollo tsa β-Si₃N₄ li etsa moralo 'me li etsa li-pores tse koetsoeng. Ka mor'a hore ho be le sintering, ho futhumatsa ho eketsehileng tlas'a mocheso o phahameng le khatello ea naetrojene ho khothalletsa phallo ea metsi le ho tlatsa, e thusang ho felisa li-pores tse koetsoeng, ho ntlafatsa le ho feta tekanyo ea li-ceramics tsa Si₃N₄. Ka hona, lisampole tse hlahisoang ke mohato oa mehato e 'meli ea sintering li bonts'a sekhahla se phahameng le sekhahla se lekanyelitsoeng ho feta se hlahisoang ke mohato o le mong oa sintering.

Phase le Microstructure Nakong ea sintering e le 'ngoe, nako e teng bakeng sa ho hlophisa bocha le ho arola moeli oa lijo-thollo e lekanyelitsoe. Ts'ebetsong ea sintering ea mehato e 'meli, mohato oa pele o etsoa ka mocheso o tlase le khatello e tlase ea khase, e leng ho eketsang nako ea ho hlophisa bocha le ho hlahisa lijo-thollo tse kholoanyane. Joale mocheso o eketseha ho ea boemong ba mocheso o phahameng, moo lijo-thollo li tsoelang pele ho hōla ka mokhoa oa ho butsoa ha Ostwald, ho fana ka li-ceramics tsa Si₃N₄ tse phahameng haholo.

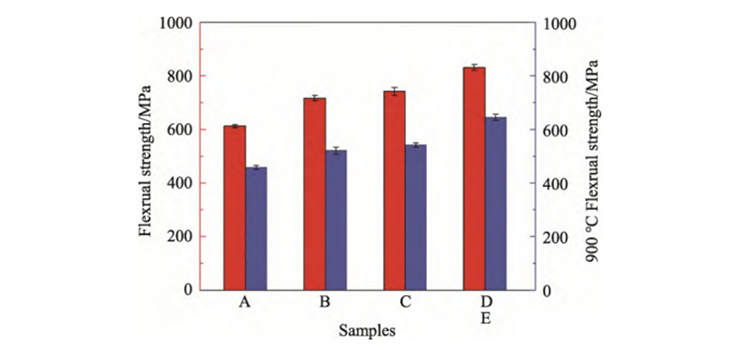

Thepa ea Mechanical Ho nolofala ha karolo ea intergranular mocheso o phahameng ke lebaka le ka sehloohong la ho fokotsa matla. Ka mohato o le mong oa sintering, khōlo e sa tloaelehang ea lijo-thollo e etsa li-pores tse nyenyane pakeng tsa lijo-thollo, tse thibelang ntlafatso e kholo ea matla a phahameng a mocheso. Leha ho le joalo, ts'ebetsong ea sintering ea mehato e 'meli, karolo ea khalase, e arolelitsoeng ka mokhoa o ts'oanang meeling ea lijo-thollo,' me lithollo tsa boholo bo lekanang li matlafatsa matla a intergranular, e leng se etsang hore ho be le matla a holimo a phahameng a mocheso.

Qetellong, ho ts'oara nako e telele nakong ea sintering e le 'ngoe ho ka fokotsa porosity ea ka hare ka katleho le ho finyella mmala o tšoanang oa ka hare le sebopeho empa ho ka lebisa khōlong e sa tloaelehang ea lijo-thollo, e senyang thepa e itseng ea mechine. Ka ho sebelisa mehato e 'meli ea sintering-ho sebelisa mocheso o tlase oa pre-sintering ho eketsa nako ea ho hlophisa bocha le mocheso o phahameng ho khothaletsa kholo ea lijo-thollo tse tšoanang - Si₃N₄ ceramic e nang le boholo ba 98.25%, microstructure e ts'oanang, le thepa e ntle haholo ea mochine. e ka lokisoa ka katleho.

| Lebitso | Substrate | Sebopeho sa Epitaxial layer | Mokhoa oa Epitaxial | Epitaxial medium |

| Silicon homoepitaxial | Si | Si | Vapor Phase Epitaxy (VPE) | SiCl4+H2 |

| Silicon heteroepitaxial | Sapphire kapa spinel | Si | Vapor Phase Epitaxy (VPE) | SiH₄+H₂ |

| Homoepitaxial ea GaAs | Li-GaAs | Li-GaAs Li-GaAs | Vapor Phase Epitaxy (VPE) | AsCl₃+Ga+H₂ (Ar) |

| Li-GaAs | Li-GaAs Li-GaAs | Molecular Beam Epitaxy (MBE) | Ga+As | |

| GaAs heteroepitaxial | Li-GaAs Li-GaAs | GaAlAs/GaAs/GaAlAs | Liquid Phase Epitaxy (LPE) Phase ea Mouoane (VPE) | Ga+Al+CaAs+ H2 Ga+AsH3+PH3+CHl+H2 |

| Homoepitaxial ea GaP | Lekhalo | Lekhalo(GaP;N) | Liquid Phase Epitaxy (LPE) Liquid Phase Epitaxy (LPE) | Ga+GaP+H2+(NH3) Ga+Gas+GaP+NH3 |

| Superlattice | Li-GaAs | GaAlAs/GaAs (baesekele) | Molecular Beam Epitaxy (MBE) MOCVD | Ca, As, Al GaR₃+AlR3+AsH3+H2 |

| InP homoepitaxial | InP | InP | Vapor Phase Epitaxy (VPE) Liquid Phase Epitaxy (LPE) | PCl3+In+H2 Ho+InAs+GaAs+InP+H₂ |

| Si/GaAs Epitaxy | Si | Li-GaAs | Molecular Beam Epitaxy (MBE) MOGVD | Ga, joalo ka GaR₃+AsH₃+H₂ |

Nako ea poso: Dec-24-2024