Tantalum carbide (TaC)ke motsoako oa binary oa tantalum le carbon o nang le foromo ea lik'hemik'hale TaC x, moo x hangata e fapaneng pakeng tsa 0.4 le 1. Ke lisebelisoa tsa ceramic tse thata ka ho fetisisa, tse brittle, tse refractory tse nang le conductivity ea tšepe. Ke phofshoana e sootho-grey 'me hangata e sebetsoa ka ho sintering.

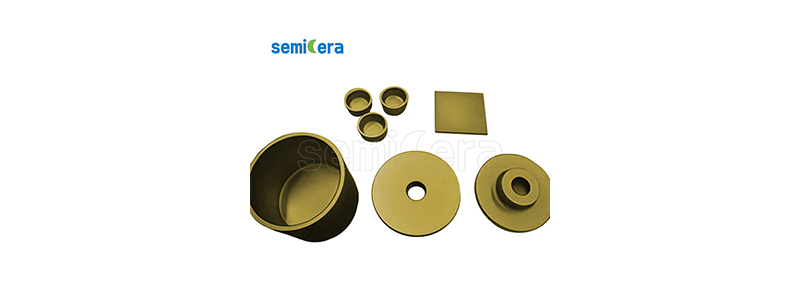

Tantalum carbideke thepa ea bohlokoa ea tšepe ea ceramic. Tšebeliso e 'ngoe ea bohlokoa haholo ea tantalum carbide ke tantalum carbide coating.

Litšobotsi tsa sehlahisoa sa tantalum carbide coating

Boemo bo phahameng ba ho qhibiliha: Sebaka sa ho qhibiliha satantalum carbidee phahame joalo ka3880°C, e etsang hore e be e tsitsitseng libakeng tse phahameng tsa mocheso 'me ho se bonolo ho qhibiliha kapa ho senya.

Boemo ba ho sebetsa :Ka kakaretso, boemo bo tloaelehileng ba Mosebetsi oa Tantalum carbide (TaC) ke 2200°C. Ha ho nahanoa ka sebaka sa eona sa ho qhibiliha se phahameng haholo, TaC e etselitsoe ho mamella mocheso o phahameng joalo ntle le ho lahleheloa ke sebopeho sa eona sa botšepehi.

Ho thatafala le ho hanyetsa ho apara: E na le boima bo phahameng ka ho fetisisa (bothata ba Mohs bo ka bang 9-10) 'me bo khona ho hanela ho roala le ho mengoa.

Ho tsitsa ha lik'hemik'hale: E na le botsitso bo botle ba lik'hemik'hale ho li-acids tse ngata le alkalis 'me e khona ho hanela kutu le liphetoho tsa lik'hemik'hale.

Thermal conductivity: Ts'ebetso e ntle ea mocheso e etsa hore e khone ho qhalakanya hantle le ho tsamaisa mocheso, ho fokotsa tšusumetso ea ho bokella mocheso holim'a thepa.

Maemo a kopo le melemo ho indasteri ea semiconductor

Lisebelisoa tsa MOCVD: Sesebelisoa sa MOCVD (chemical vapor deposition)litlolo tsa tantalum carbideli sebelisetsoa ho sireletsa kamore ea karabelo le likarolo tse ling tsa mocheso o phahameng, ho fokotsa khoholeho ea thepa ka li-deposit, le ho lelefatsa bophelo ba tšebeletso ea thepa.

Melemo: Ntlafatsa ho hanyetsa mocheso o phahameng oa lisebelisoa, fokotsa makhetlo a tlhokomelo le litšenyehelo, le ho ntlafatsa katleho ea tlhahiso.

Ts'ebetso ea Wafer: E sebelisoa lits'ebetsong tsa phetisetso le phetisetso ea liphaephe, liphahlo tsa tantalum carbide li ka ntlafatsa ho hanyetsa le ho hanyetsa hoa ha thepa.

Melemo: Fokotsa mathata a boleng ba sehlahisoa a bakoang ke ho senyeha kapa ho senyeha, 'me u netefatse botsitso le botsitso ba ho sebetsa ha li-wafer.

Lisebelisoa tsa ts'ebetso ea semiconductor: Ka lisebelisoa tsa ts'ebetso ea semiconductor, tse kang li-implanters tsa ion le li-etchers, liphahlo tsa tantalum carbide li ka ntlafatsa ho tšoarella ha lisebelisoa.

Melemo: Eketsa bophelo ba ts'ebeletso ea lisebelisoa, fokotsa nako le litšenyehelo tsa ho nchafatsa, 'me u ntlafatse katleho ea tlhahiso.

Libaka tse phahameng tsa mocheso: Likarolong tsa elektronike le lisebelisoa libakeng tse phahameng tsa mocheso, liphahlo tsa tantalum carbide li sebelisoa ho sireletsa thepa ho tloha mocheso o phahameng.

Melemo: Etsa bonnete ba botsitso le ho tšepahala ha likarolo tsa elektronike tlas'a maemo a feteletseng a mocheso.

Mekhoa ea Tsoelo-pele ea Bokamoso

Ntlafatso ea Lintho: Ka ntshetsopele ya mahlale a lintho tse bonahalang, thekenoloji le deposition thekenoloji ealitlolo tsa tantalum carbidee tla tsoela pele ho ntlafatsa ho ntlafatsa ts'ebetso ea eona le ho fokotsa litšenyehelo. Ka mohlala, ho ka 'na ha etsoa lisebelisoa tsa ho roala tse tšoarellang nako e telele le tse theko e tlaase.

Theknoloji ea Deposition: Ho tla khonahala ho ba le mahlale a matle le a nepahetseng a ho beha, joalo ka mahlale a ntlafalitsoeng a PVD le CVD, ho ntlafatsa boleng le ts'ebetso ea liphahlo tsa tantalum carbide.

Libaka tse Ncha tsa Kopo: Libaka tsa kopo ealitlolo tsa tantalum carbidee tla atoloha ho ea libakeng tse ngata tsa theknoloji e phahameng le tsa indasteri, joalo ka liindasteri tsa sefofane, matla le likoloi, ho fihlela tlhoko ea lisebelisoa tse sebetsang hantle haholo.

Nako ea poso: Aug-08-2024