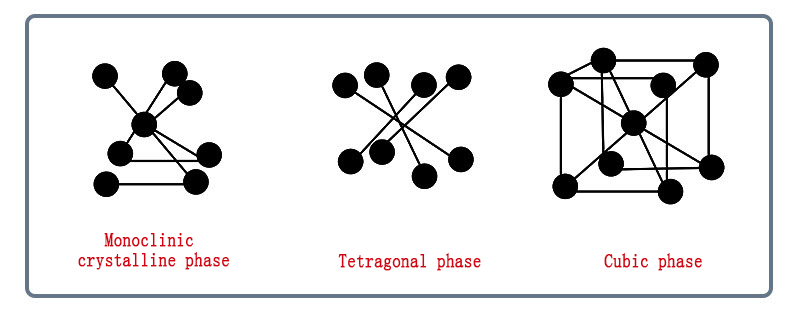

Li-ceramics tsa zirconiali tšoeu, li mosehla kapa tse thokoa ha li na le litšila, 'me ka kakaretso li na le HfO2, eo ho seng bonolo ho e arola. Ho na le linaha tse tharo tsa kristale tsa ZrO2 tse hloekileng tlas'a khatello e tloaelehileng.

■Mocheso o tlase oa monoclinic (m-ZrO2)■Mocheso o mahareng oa tetragonal (t-ZrO2)■Mocheso o phahameng oa cubic (c-ZrO2)

Mefuta e meraro e kaholimo ea kristale e teng maemong a fapaneng a mocheso, 'me ho na le likamano tse latelang tsa phetoho:

Litšobotsi tsa li-ceramics tsa zirconia

Hho qhibidiha-boima

Sebaka se qhibilihang sa Zirconia ke: 2715 ℃, se ka sebelisoa e le thepa e thibelang mocheso o phahameng.

Boima bo phahameng, ho hanyetsa ho apara hantle

Ho latela boima ba Mohs: safire >Li-ceramics tsa zirconia> Corning Glass > Aluminium magnesium alloy > Tempered glass > polycarbonate

Matla a phahameng le ho tiea

Matla a zirconia a ka fihla: 1500MPa

Mocheso o tlase oa conductivity le coefficient ea katoloso

Har'a lisebelisoa tse tloaelehileng tsa ceramic, conductivity ea eona ea mocheso ke e tlaase ka ho fetisisa (1.6-2.03W / (mk)), 'me coefficient ea ho atolosa mocheso o haufi le oa tšepe.

Ts'ebetso e ntle ea motlakase

Motsoako oa dielectric oa zirconia ke makhetlo a 3 a safire, 'me pontšo e utloahala haholoanyane.

Tšebeliso ea li-ceramics tsa zirconia

Li-ceramics tsa zirconiali sebelisoa haholo ho lisebelisoa tsa elektroniki tsa 3C, puisano ea optical, smart wear, biomedical, mabenyane, bophelo ba letsatsi le letsatsi, lisebelisoa tsa refractory le likarolo tse ling.

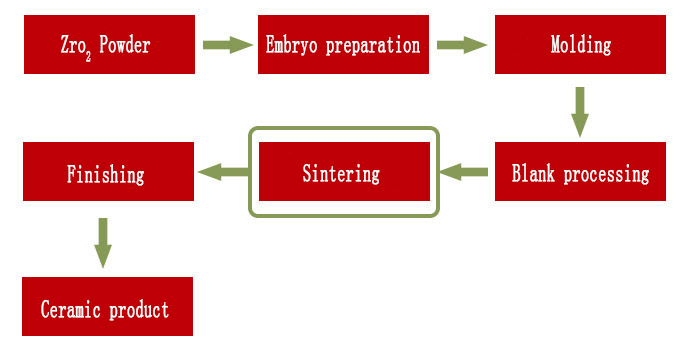

Theknoloji ea ho lokisa sehlahisoa sa Zirconia ceramic

Sintering ke ts'ebetso ea bohlokoa haholo tokisong eali-ceramics tsa zirconia, boleng ba sintering bo tla ama ka ho toba ts'ebetso ea ceramic, feela mocheso oa sintering o lokisoa hantle, 'mele oa eona oa embryo o tla ba o phethahetseng. Sintering e se nang khatello ke mokhoa o sebelisoang haholo oa sintering.

Hobane ka linako tse ling lisebelisoa tse hloekileng tsa ceramic li thata ho sintering, tlas'a maemo a ts'ebetso, li-additives tse ling tsa sintering li atisa ho hlahisoa ho theha sebaka se tlaase sa ho qhibiliha sa tharollo e tiileng, karolo ea khalase kapa karolo e 'ngoe ea metsi, ho khothalletsa ho hlophisoa bocha ha likaroloana le phallo ea viscous. , e le ho fumana sehlahisoa se teteaneng, empa hape le ho fokotsa mocheso oa sintering.

Ho fokotsa boholo ba phofo ka hohle kamoo ho ka khonehang hape ke e 'ngoe ea mehato ea bohlokoa ea ho khothalletsa sintering. Hobane ha phofshoana e le ntle, matla a holimo a phahame, ho nolofatsa sintering. Bakeng sa lisebelisoa tsa ceramic le lihlahisoa tse nang le litlhoko tse tloaelehileng tsa ts'ebetso, sintering e se nang khatello ke mokhoa o bonolo ka ho fetisisa le oa moruo oa sintering.

Nako ea poso: Jul-24-2023