Ho tlohacruciblee sebelisoa e le setshelo 'me ho na le convection ka hare, ha boholo ba generated kristale e le' ngoe e eketseha, mocheso convection le mocheso gradient ho tšoana ho ba thata ho laola. Ka ho eketsa matla a khoheli ho etsa hore conductive e qhibilihe e sebetse ka matla a Lorentz, convection e ka fokotsoa kapa ea felisoa ho hlahisa silicon e le 'ngoe ea boleng bo holimo.

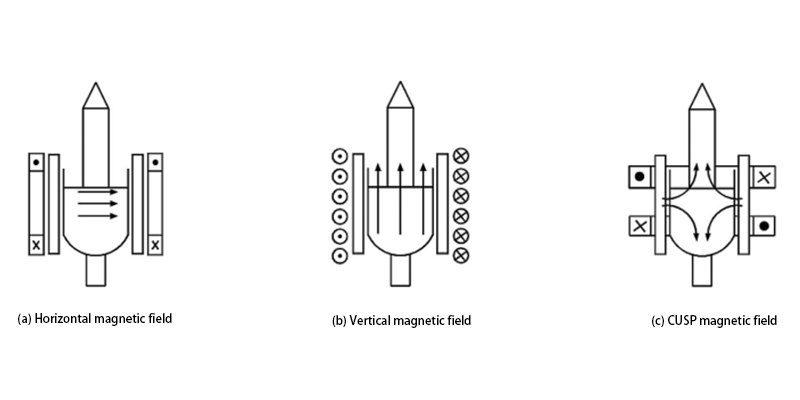

Ho latela mofuta oa matla a khoheli, e ka aroloa ka matla a khoheli a otlolohileng, matla a khoheli a emeng le matla a khoheli a CUSP:

Matla a khoheli a emeng ha a khone ho felisa convection e kholo ka lebaka la mabaka a sebopeho mme ha a sebelisoe hangata.

Tataiso ea karolo ea matla a khoheli ea matla a khoheli e tšekaletseng e shebane le mocheso o moholo oa mocheso le karolo e itseng e qobelloang ea lerako la crucible, e ka thibelang ho sisinyeha ka nepo, ho boloka ho bata ha sebopeho sa kholo, le ho fokotsa mela ea kholo.

Matla a khoheli a CUSP a na le phallo e ts'oanang le phetisetso ea mocheso ea ho qhibiliha ka lebaka la ho lekana ha eona, kahoo lipatlisiso tsa matla a khoheli a emeng le a CUSP li ntse li tsamaisana.

China, Xi'an University of Technology e hlokometse tlhahiso le liteko tsa ho hula kristale tsa silicon e le 'ngoe ea likristale tse sebelisang matla a khoheli pejana. Lihlahisoa tsa eona tse ka sehloohong ke mefuta e 6-8in e tsebahalang, e lebisitsoeng 'marakeng oa silicon wafer bakeng sa lisele tsa letsatsi tsa photovoltaic. Linaheng tsa linaheng tse ling, tse kang KAYEX United States le CGS Jeremane, lihlahisoa tsa bona tse ka sehloohong ke 8-16in, tse loketseng melamu e le 'ngoe ea silicon ea kristale boemong ba li-circuits le li-semiconductors tse kholo tse kholo. Ba na le monopoly tšimong ea matla a khoheli bakeng sa kholo ea likristale tse le 'ngoe tsa boleng bo phahameng ba bophara bo boholo' me ke bona ba emetseng ka ho fetisisa.

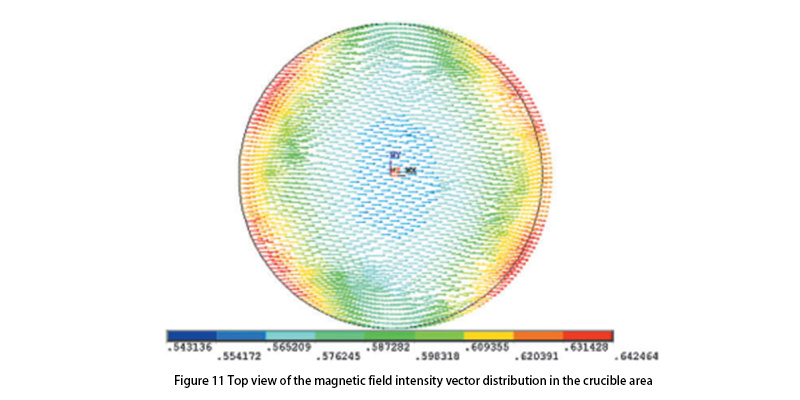

Kabo ea matla a khoheli sebakeng sa crucible ea sistimi e le 'ngoe ea kholo ea kristale ke karolo ea bohlokoahali ea makenete, ho kenyeletsoa matla le ho ts'oana ha matla a khoheli pheletsong ea crucible, setsi sa crucible, le se nepahetseng. sebaka se ka tlasa metsi. Ka kakaretso rapameng le junifomo transverse matla a khoheli, matla a khoheli mela e perpendicular ho kristale kgolo axis. Ho ea ka phello ea makenete le molao oa Ampere, coil e haufi haholo le moeli oa crucible 'me matla a tšimo ke a maholo ka ho fetisisa. Ha sebaka se ntse se eketseha, ho hanyetsa matla a matla a moea hoa eketseha, matla a tšimo a fokotseha butle-butle, 'me ke e nyenyane ka ho fetisisa bohareng.

Karolo ea superconducting magnetic field

Ho thibela mocheso oa mocheso: Ha ho se na matla a khoheli a ka ntle, silicon e qhibilihisitsoeng e tla hlahisa convection ea tlhaho nakong ea mocheso, e leng se ka lebisang ho aroleng litšila tse sa tšoaneng le ho thehoa ha bokooa ba kristale. Matla a khoheli a kantle a ka hatella convection ena, a etsa hore mocheso oa mocheso o qhibilihe ka har'a mokelikeli o ts'oanang le ho fokotsa kabo e sa lekanang ea litšila.

Ho laola sekhahla sa kholo ea kristale: Matla a khoheli a ka ama sekhahla le tataiso ea kholo ea kristale. Ka ho laola ka nepo matla le kabo ea matla a khoheli, ts'ebetso ea kholo ea kristale e ka ntlafatsoa mme botšepehi le ho ts'oana ha kristale li ka ntlafatsoa. Nakong ea kholo ea silicon e le 'ngoe ea kristale, oksijene e kena ka silicon e qhibiliha haholo-holo ka motsamao o lekanyelitsoeng oa ho qhibiliha le crucible. Matla a khoheli a fokotsa monyetla oa hore oksijene e kopane le silicon e qhibiliha ka ho fokotsa phepelo ea ho qhibiliha, kahoo e fokotsa ho qhibiliha ha oksijene. Maemong a mang, matla a khoheli a ka ntle a ka fetola maemo a thermodynamic a ho qhibiliha, joalo ka ho fetola tsitsipano ea holim'a ho qhibiliha, e ka thusang ho fetoha ha oksijene, ka hona ho fokotsa litaba tsa oksijene ho qhibiliha.

Fokotsa ho qhibiliha ha oksijene le litšila tse ling: Oksijene ke e 'ngoe ea litšila tse tloaelehileng khōlong ea likristale tsa silicon, tse tla etsa hore boleng ba kristale bo senyehe. Matla a khoheli a ka fokotsa litaba tsa oksijene ha a qhibiliha, ka hona a fokotsa ho qhibiliha ha oksijene ka har'a kristale le ho ntlafatsa bohloeki ba kristale.

Ntlafatsa sebopeho sa ka hare sa kristale: Matla a khoheli a ka ama sebopeho sa sekoli ka har'a kristale, joalo ka ho kheloha le meeli ea lijo-thollo. Ka ho fokotsa palo ea mefokolo ena le ho ama kabo ea bona, boleng ba kristale ka kakaretso bo ka ntlafatsoa.

Ho ntlafatsa thepa ea motlakase ea likristale: Kaha matla a khoheli a na le phello e kholo ho microstructure nakong ea kholo ea kristale, a ka ntlafatsa thepa ea motlakase ea likristale, tse kang resistivity le carrier lifetime, tse bohlokoa bakeng sa ho etsa lisebelisoa tse phahameng tsa semiconductor.

Amohela bareki leha e le bafe ba tsoang lefats'eng lohle ho re etela bakeng sa puisano e eketsehileng!

https://www.semi-cera.com/

https://www.semi-cera.com/tac-coating-monocrystal-growth-parts/

https://www.semi-cera.com/cvd-coating/

Nako ea poso: Jul-24-2024