Tšimoloho ea Lebitso "Epitaxial Wafer"

Tokiso ea Wafer e na le mehato e 'meli e meholo: ho lokisoa ha substrate le ts'ebetso ea epitaxial. The substrate e entsoe ka semiconductor single crystal material mme hangata e sebetswa ho hlahisa disebediswa tsa semiconductor. E ka boela ea etsoa epitaxial processing ho theha epitaxial wafer. Epitaxy e bua ka mokhoa oa ho holisa lera le lecha la kristale le lecha holim'a substrate e le 'ngoe ea kristale e sebetsitsoeng ka hloko. Kristale e ncha e le 'ngoe e ka ba ea thepa e tšoanang le substrate (homogeneous epitaxy) kapa thepa e fapaneng (heterogeneous epitaxy). Kaha lesela le lecha la kristale le ntse le hola ka tumellano le sebopeho sa kristale sa substrate, se bitsoa epitaxial layer. Sephaphatha se nang le epitaxial layer se bitsoa sephaphatha sa epitaxial (epitaxial wafer = epitaxial layer + substrate). Lisebelisoa tse entsoeng holim'a epitaxial layer li bitsoa "forward epitaxy," ha lisebelisoa tse entsoeng holim'a substrate li bitsoa "reverse epitaxy," moo epitaxial layer e sebetsang feela e le tšehetso.

Homogeneous le Heterogeneous Epitaxy

▪Homogeneous Epitaxy:Epitaxial layer le substrate li entsoe ka thepa e tšoanang: mohlala, Si / Si, GaAs / GaAs, GaP / GaP.

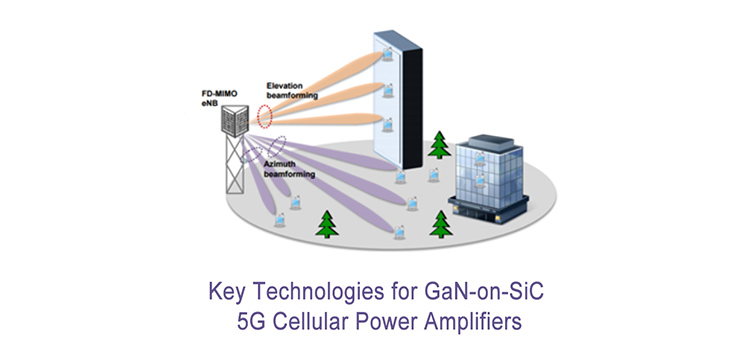

▪Heterogeneous Epitaxy:Epitaxial layer le substrate li entsoe ka lisebelisoa tse fapaneng: mohlala, Si/Al₂O₃, GaS/Si, GaAlAs/GaAs, GaN/SiC, joalo-joalo.

Li-wafers tse hloekisitsoeng

Epitaxy e Rarolla Mathata afe?

Lisebelisoa tse ngata tsa kristale e le 'ngoe feela ha li lekane ho fihlela litlhoko tse ntseng li eketseha tsa ho etsoa ha lisebelisoa tsa semiconductor. Ka hona, ho elella bofelong ba 1959, mokhoa o mosesaane oa ho holisa kristale o le mong o tsejoang e le epitaxy o ile oa ntlafatsoa. Empa theknoloji ea epitaxial e thusitse joang ka ho khetheha tsoelo-pele ea thepa? Bakeng sa silicon, nts'etsopele ea silicon epitaxy e etsahetse ka nako e mahlonoko ha ho etsoa ha li-transistors tsa silicon tse phahameng-frequency, tse nang le matla a phahameng li tobane le mathata a maholo. Ho ea ka pono ea melao-motheo ea transistor, ho fihlella maqhubu a phahameng le matla ho hloka hore motlakase oa sebaka sa mokekelli o be holimo, 'me letoto la ho hanyetsa le be tlase, ho bolelang hore motlakase oa saturation o lokela ho ba nyane. Ea pele e hloka ho hanyetsa ho phahameng ka thepa ea mokelli, ha ea morao-rao e hloka ho hanyetsa ho tlaase, e leng se bakang ho hanyetsana. Ho fokotsa botenya ba sebaka sa mokelli ho fokotsa khanyetso ea letoto ho ka etsa hore sephaphatha sa silicon se be tšesaane haholo 'me se senyehe hore se ka sebetsoa, 'me ho theola matla a ho hanyetsa ho tla hohlana le tlhoko ea pele. Tsoelo-pele ea theknoloji ea epitaxial e ile ea rarolla bothata bona ka katleho. Tharollo e ne e le ho hōlisa sekhahla se phahameng sa resistivity epitaxial holim'a substrate e tlaase-resistivity. Sesebelisoa se entsoe ka lera la epitaxial, ho netefatsa hore ho na le matla a phahameng a ho senyeha ha transistor, athe substrate e tlaase-resistivity e fokotsa khanyetso ea motheo le ho theola matla a saturation, ho rarolla ho hanyetsana pakeng tsa litlhoko tse peli.

Ntle le moo, mahlale a epitaxial bakeng sa li-semiconductors tsa III-V le II-VI tse joalo ka GaAs, GaN, le tse ling, ho kenyeletsoa karolo ea mouoane le epitaxy ea mokelikeli, li bone tsoelo-pele e kholo. Litheknoloji tsena li fetohile tsa bohlokoa bakeng sa ho etsoa ha lisebelisoa tse ngata tsa microwave, optoelectronic, le matla. Haholo-holo, mekhoa e kang molecular beam epitaxy (MBE) le metal-organic chemical vapor deposition (MOCVD) li 'nile tsa sebelisoa ka katleho ho likarolo tse tšesaane, li-superlattices, liliba tsa quantum, superlattices e thata, le likaroloana tse tšesaane tsa epitaxial tsa atomic, tse ralang motheo o tiileng oa nts'etsopele ea masimo a macha a semiconductor joalo ka "band engineering."

Lits'ebetsong tse sebetsang, lisebelisoa tse ngata tse pharaletseng tsa semiconductor li entsoe ka likarolo tsa epitaxial, ka thepa e kang silicon carbide (SiC) e sebelisoang feela e le li-substrates. Ka hona, ho laola sekhahla sa epitaxial ke ntlha ea bohlokoa indastering ea semiconductor e pharaletseng ea li-bandgap.

Theknoloji ea Epitaxy: Likarolo tse Supileng tsa Bohlokoa

1. Epitaxy e ka hōlisa sekhahla se phahameng (kapa se tlaase) sa resistivity ka substrate e tlaase (kapa e phahameng) ea resistivity.

2. Epitaxy e lumella ho hōla ha mefuta ea N (kapa P) ea mofuta oa epitaxial ho li-substrates tsa mofuta oa P (kapa N), ka ho toba ho theha PN junction ntle le mathata a matšeliso a hlahang ha ho sebelisoa diffusion ho theha motsoako oa PN holim'a substrate e le 'ngoe ea kristale.

3. Ha e kopantsoe le theknoloji ea mask, khōlo ea epitaxial e khethiloeng e ka etsoa libakeng tse itseng, e leng ho nolofalletsang ho etsoa ha lipotoloho tse kopantsoeng le lisebelisoa tse nang le mehaho e khethehileng.

4. Khōlo ea Epitaxial e lumella ho laola mefuta ea doping le ho tsepamisa maikutlo, ka bokhoni ba ho finyella liphetoho tse potlakileng kapa tse fokolang tsa mahloriso.

5. Epitaxy e ka hōla ka mefuta e mengata, e nang le mefuta e mengata, e nang le likarolo tse ngata tse nang le mefuta e sa tšoaneng, ho kenyelletsa le li-ultra-thin layers.

6. Khōlo ea Epitaxial e ka etsahala ka mocheso o ka tlaase ho ntlha ea ho qhibiliha ea thepa, ka tekanyo ea ho hōla e laolehang, e lumellang ho nepahala ha boemo ba athomo ka botenya ba lera.

7. Epitaxy e nolofalletsa ho hōla ha likarolo tse le 'ngoe tsa kristale tsa lisebelisoa tse ke keng tsa huloa ka har'a likristale, tse kang GaN le ternary / quaternary compound semiconductors.

Mefuta e sa tšoaneng ea Epitaxial Layers le Epitaxial Processes

Ka kakaretso, likarolo tsa epitaxial li fana ka sebopeho sa kristale se laoloang habonolo le se phethahetseng ho feta li-substrates tse ngata, tse molemo bakeng sa nts'etsopele ea lisebelisoa tse tsoetseng pele.

Nako ea poso: Dec-24-2024