Tlhoekiso le Limmapa

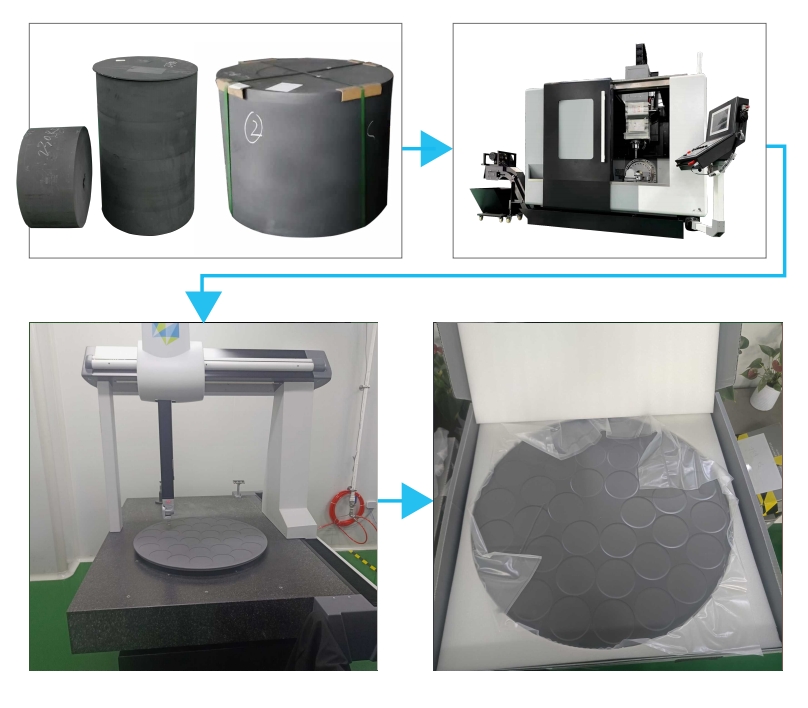

Ts'ebeletso ea rona e akaretsa tlhoekiso le 'mapa oa lisebelisoa tse fapaneng tsa semiconductor, ka sepheo sa ho fana ka lisebelisoa tsa boleng bo holimo tsa semiconductor bakeng sa lits'ebetso tse fapaneng. Ka ho sebelisa theknoloji ea rona e tsoetseng pele ea tlhoekiso le lisebelisoa tsa morao-rao, re felisa litšila ka katleho, kahoo re ntlafatsa bohloeki ba thepa ea semiconductor. Ts'ebetso ea rona ea tlhoekiso e entsoe ka makhethe, e kenyelletsang mehato e mengata le mehato e tiileng ea taolo ea boleng ho netefatsa bohloeki bo ikhethang le botsitso ba lisebelisoa tseo re fanang ka tsona.

Ho feta moo, re ikemiselitse ho fa bareki ba rona litšebeletso tsa 'mapa tse nepahetseng le tse tšepahalang. Re na le lisebelisoa tse tsoetseng pele tsa tlhahlobo le lisebelisoa, 'me re tšehetsoa ke sehlopha sa litsebi tse nang le boiphihlelo, re khona ho etsa litekanyo tse felletseng le ho sekaseka litšobotsi tsa thepa ea semiconductor. Litšebeletso tsa rona tsa 'mapa li kenyelletsa liteko tse ngata tse fapaneng, ho kenyeletsoa thepa ea motlakase, sebopeho, bohloeki, thepa ea 'mele, le lipatlisiso tse felletseng mabapi le sebopeho sa thepa le sebopeho. Ka ho etsa limmapa tse hlokolosi, re bokella lintlha le lintlha tse qaqileng, tse re thusang ho fa bareki litlhahlobo tse nepahetseng tsa litšobotsi tsa thepa le likhothaletso tse nepahetseng.

Bokhoni ba Mechini

Semiconductor ea Semicera e na le tšimo e ka sehloohong ea semiconductor ea graphite, silicon carbide le bokhoni bo bong ba machining le phihlelo, e ka kopanang le bareki bakeng sa lihlahisoa tsa semiconductor tse nepahetseng haholo, bohloeki bo phahameng, boleng bo phahameng le litlhoko tse ling tsa ho sebetsa. Lisebelisoa tseo re li sebelisang, mokhoa oa ho itšeha le khetho ea lisebelisoa li boetse li ntlafatsoa ka hloko ho finyella taolo ea boholo ba micron le boleng bo phahameng ba holim'a metsi. Re ela hloko taolo ea boleng le ts'ebetso ea ts'ebetso ts'ebetsong ea ts'ebetso, ho hlahloba nako ea sebele le ho laola likarolo tsa bohlokoa ts'ebetsong ea ts'ebetso ho netefatsa hore sehlahisoa se tsitsitse le botsitso. Re boetse re kenya tšebetsong tsamaiso e tiileng ea boleng ho netefatsa hore lihlahisoa li sebetsoa ho latela litlhoko tsa bareki le maemo a indasteri, le ho etsa tlhahlobo e felletseng ea boleng.

Re tla lula re tsetela ntlafatsong ea lisebelisoa le boqapi ba theknoloji ho fihlela litlhoko tse ntseng li eketseha tsa bareki ba rona le ho ba fa litharollo le tšehetso e phahameng.

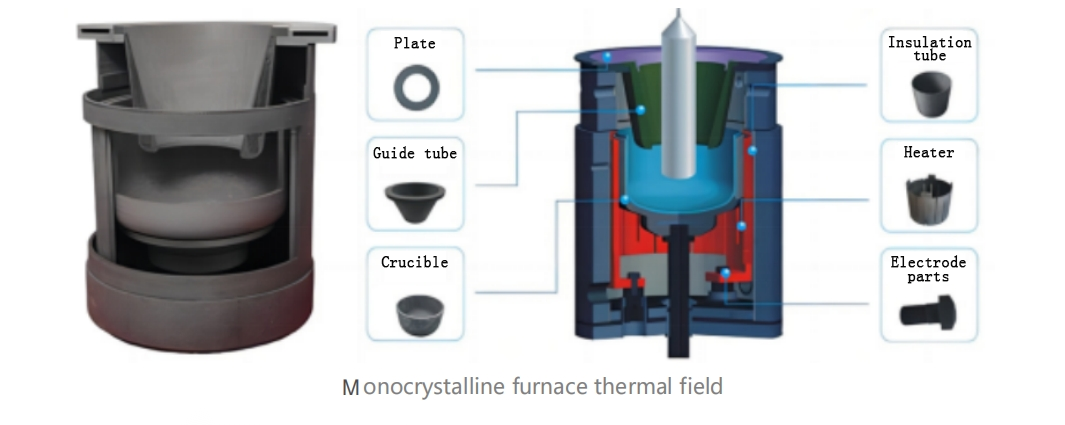

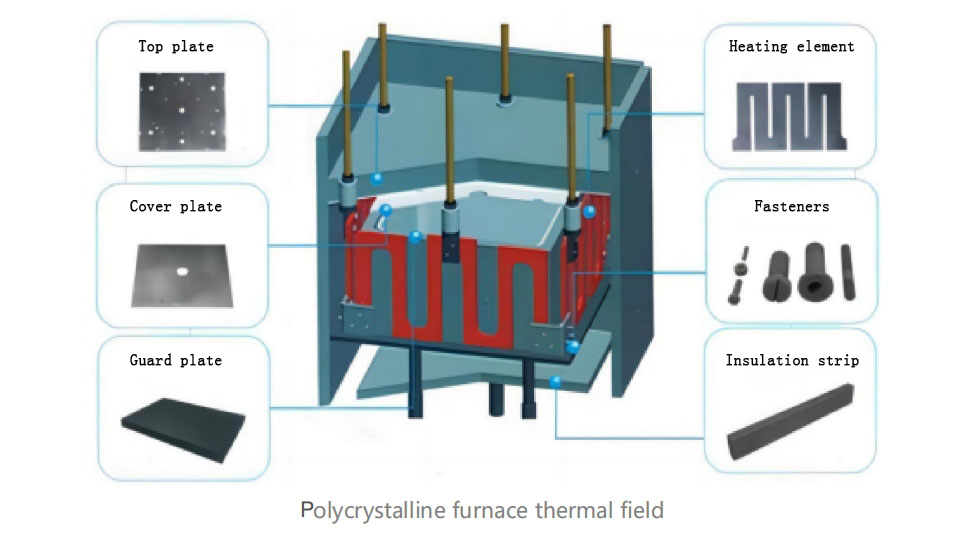

Tharollo ea Phetoho ea Tšimo ea Thermal

Mabapi le moralo oa tšimo ea mocheso le phetoho, k'hamphani ea rona e ka phethela moralo le phepelo ea batch ho Czochra single crystal, casting polycrystal, gallium arsenide, zinc selenide, safire, silicon carbide le lisebelisoa tse ling tse fapaneng tsa indasteri. Ka nako e ts'oanang, bakeng sa lipalo tse futhumatsang tsa mochini oa meaho e fapaneng, likarolo le maemo a leholimo tlas'a maemo a fapaneng a mocheso o phahameng, re boetse re na le bokhoni ba ho etsa mohlala le ketsiso ea komporo, e ka fang bareki mananeo le litlhahiso tsa ntlafatso ea moralo.

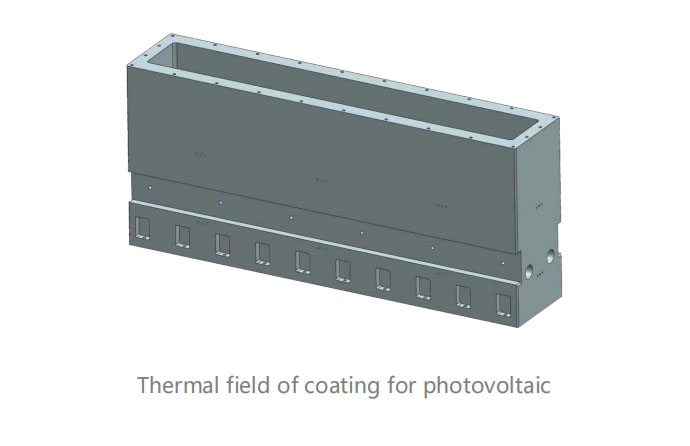

Ts'ebetsong ea ho etsa lisele tsa letsatsi, ho lokisoa ha lifilimi tse khahlanong le ho bonahatsa ke mokhoa oa bohlokoa. Lifilimi tse ka sehloohong tsa anti reflective li kenyelletsa silicon nitride/silicon oxide, e sa sebetseng feela ke lifilimi tse khahlano le tse bonahatsang empa hape e na le litlamorao tsa passivation. Ho lokisoa ha lifilimi tse khahlanong le ho bonahatsa haholo-holo ho itšetlehile ka mokhoa oa plasma enhanced vapor deposition (PECVD).

Re fana ka litharollo tse sebetsang hantle ka ho sebelisa lijari tsa morao-rao tsa PECVD tse entsoeng ka graphite ea isostatic kapa carbon fiber reinforced, joalo ka likepe tsa graphite le liforeimi tsa graphite, 'me re fana ka lits'ebeletso tsa tlhoekiso le ho roala, ho ntlafatsa ts'ebetso ea thepa.

Lisebelisoa tsa Teko ea Semiconductor

Re ikemiselitse ho fana ka lisebelisoa tse fapaneng tsa tlhahlobo ea lihlahisoa tsa semiconductor thermal field ho fihlela litlhoko tse fapaneng tsa bareki. Liteko tsa rona li akaretsa lisebelisoa tse fapaneng tsa semiconductor, ho kenyeletsoa silicon carbide, graphite, tantaluml carbide, joalo-joalo, bakeng sa tlhahlobo e felletseng ea thepa ea motlakase, sebopeho, bohloeki, thepa ea 'mele, boholo le sebopeho sa kristale. Lisebelisoa tsena tsa tlhahlobo li entsoe le ho etsoa ke sehlopha sa litsebi, se nang le lisebelisoa le lisebelisoa tsa tlhahlobo tse tsoetseng pele ho netefatsa ho nepahala le ho ts'epahala. Lisebelisoa tsa rona tsa tlhahlobo ea lihlahisoa ha li fane feela ka moralo o felletseng oa tlhahlobo, empa li kenyelletsa litlaleho tse felletseng tsa tlhahlobo le tlhahlobo ho thusa bareki ho utloisisa ts'ebetso le litaba tse ka bang teng tsa sehlahisoa.

GDMS

D-SIMS