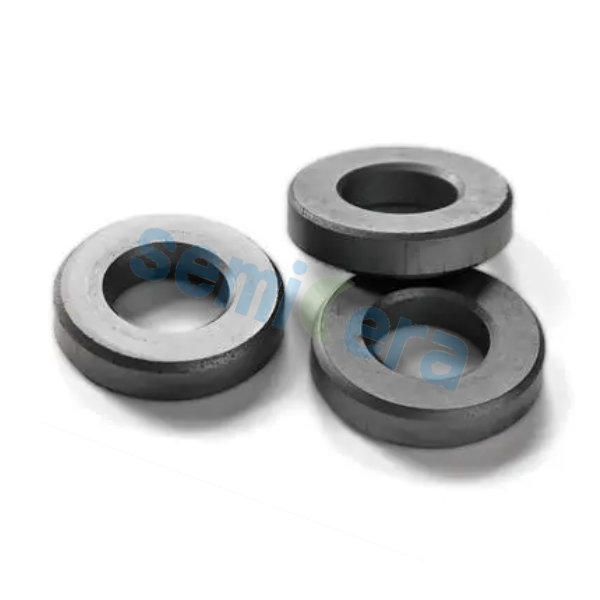

Silicon nitride ke ceramic e bohlooho e nang le bothata bo phahameng ba ho robeha, ho hanyetsa mocheso o matla haholo, le thepa e batlang e sa kenellehe ho litšepe tse qhibilihisitsoeng.

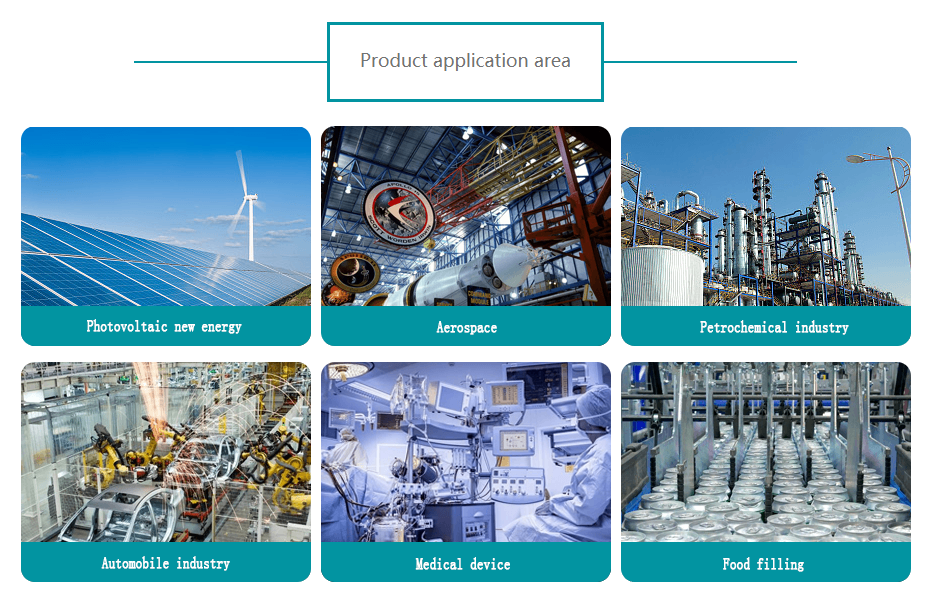

U sebelisa litšoaneleho tsena, e sebelisoa ho likarolo tsa enjene e tukang ka hare joalo ka likarolo tsa enjene ea koloi, li-nozzles tsa mochini oa welding blowpipe, joalo-joalo, haholo likarolo tse hlokang ho sebelisoa libakeng tse thata joalo ka ho futhumatsa.

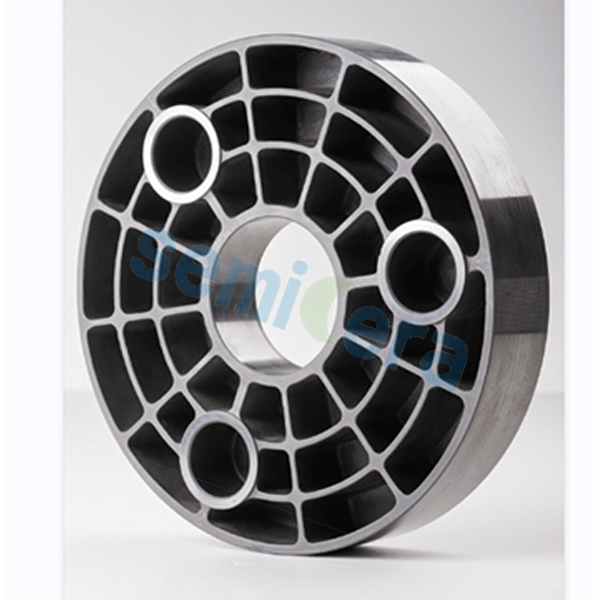

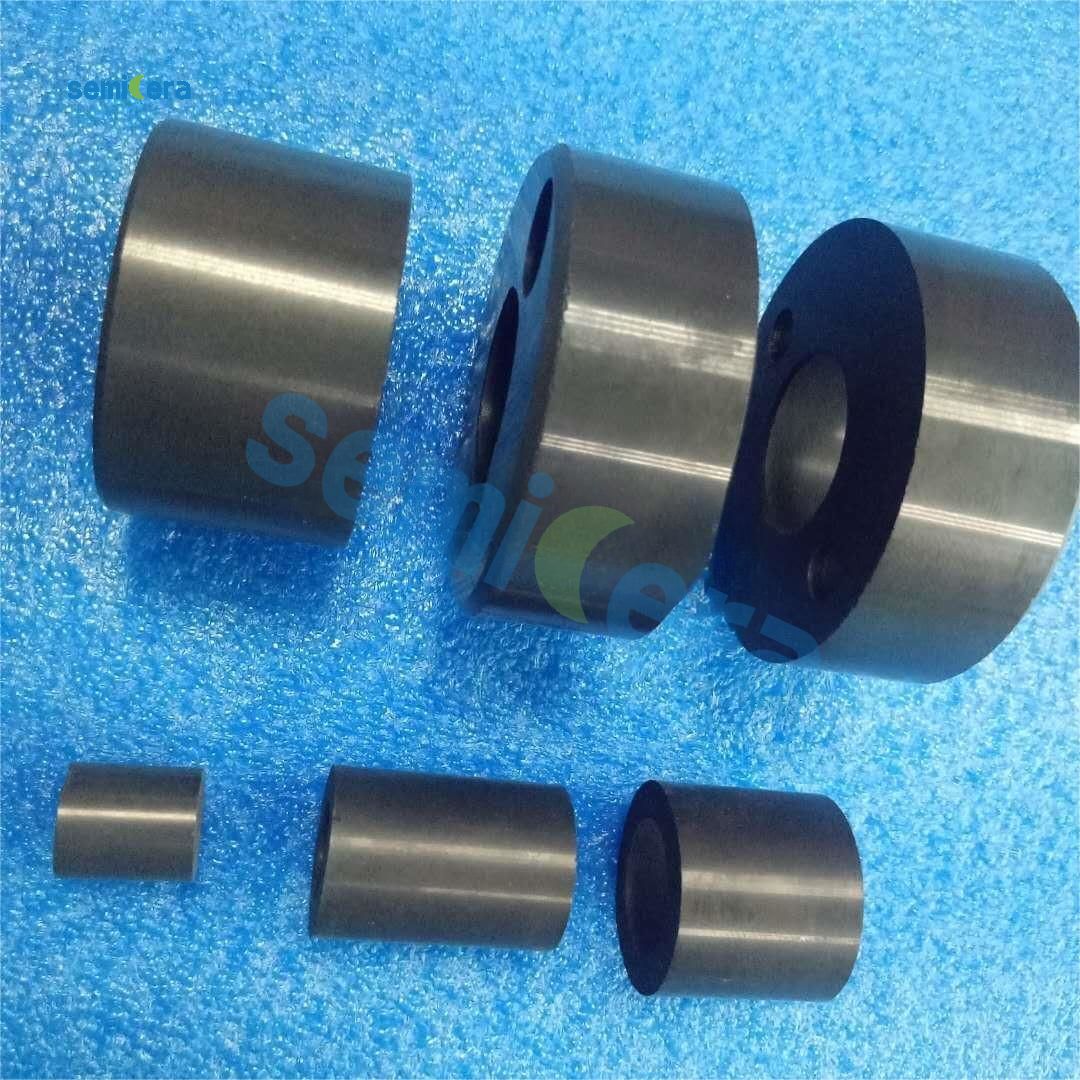

Ka khanyetso ea eona e phahameng ea ho roala le matla a phahameng a mochini, lits'ebetso tsa eona ho roala likarolo, li-bearings tse potolohang tsa shaft le lisebelisoa tsa tlhahiso ea semiconductor li ntse li eketseha.

Thepa ea silicon nitride ceramics

1, e na le matla a phahameng sebakeng se seholo sa mocheso;

2, phahameng fracture toughness;

3, matla a ho koba a matle;

4, ho hanyetsa mokhathala oa mochine le ho fofa;

5, khanya - tlaase segokanyipalo;

6, boima bo phahameng le ho apara ho hanyetsa;

7, ho hanyetsa mocheso o babatsehang oa mocheso;

8, katoloso e tlase ea mocheso;

9, insulator ea motlakase;

10, khanyetso e ntle ea oxidation;

11, khanyetso e ntle ea kutu ea lik'hemik'hale.

Li-ceramics tsa silicon nitride li na le coefficient e tlase ea katoloso ea mocheso le conductivity e phahameng ea mocheso, kahoo li na le khanyetso e ntle ea mocheso.Silicon nitride e hatelitsoeng ka mocheso o chesang e ke ke ea robeha ka mor'a ho futhumatsoa ho 1000 ℃ ebe e kenngoa ka metsing a batang.Ha mocheso o sa phahame haholo, silicon nitride e na le matla a phahameng le ho hanyetsa tšusumetso, empa ka holimo ho 1200 ℃ e tla senyeha ka kholo ea nako ea tšebeliso, e le hore matla a eona a fokotsehe, a kotsing ea ho senyeha ha mokhathala ka holimo ho 1450 ℃, kahoo tšebeliso ea eona e fokotsehile. mocheso oa Si3N4 ka kakaretso ha o fete 1300 ℃.

Ka hona, silicon nitride e sebelisitsoe haholo ho:

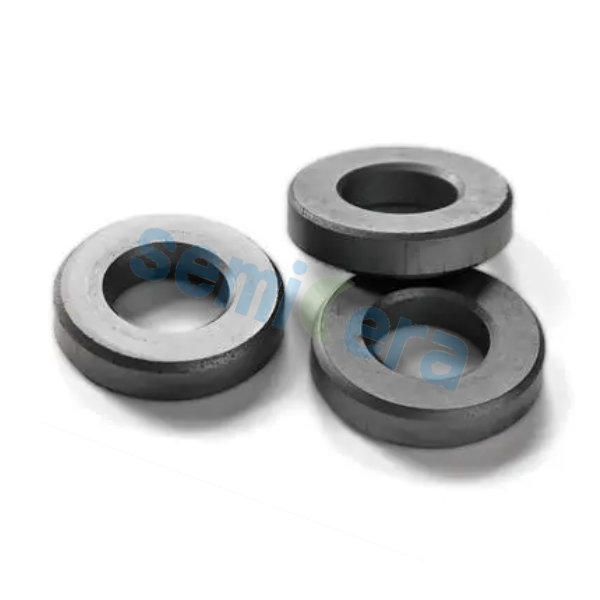

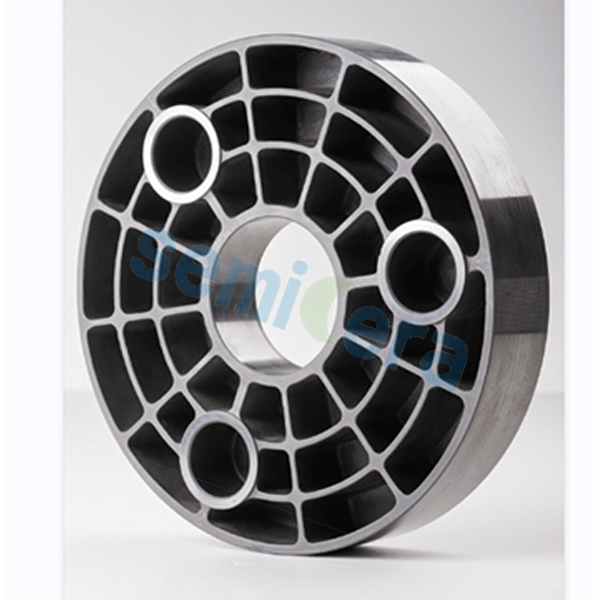

1. Ho potoloha ha bolo le li-roller bearings;

2. Likarolo tsa enjene: valve, letlapa la letsoho la rocker, sebaka sa ho tiisa;

3. Induction futhumatsang bracket coil;

4. Li-blades tsa turbine, li-blades, linkho;

5. Lisebelisoa tsa ho cheselletsa le ho tiisa;

6. Kopano ea lintho tse futhumatsang;

7. Welding positioner;

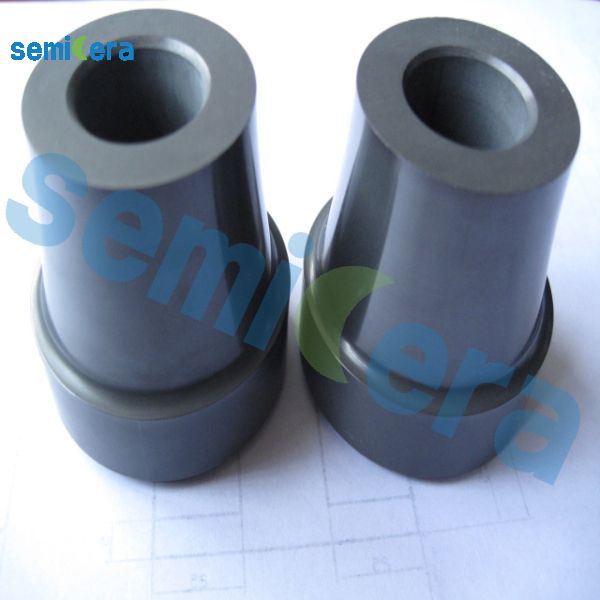

8. Li-shafts tse nepahetseng le matsoho libakeng tse apereng liaparo tse phahameng;

9. Thermocouple sheath le tube;

10. Lisebelisoa tsa ts'ebetso ea semiconductor.

-

Lihlahisoa tsa SiC ceramic SiC optical reflector

-

Thepa ea laser microjet cutting (LMJ) e ka ...

-

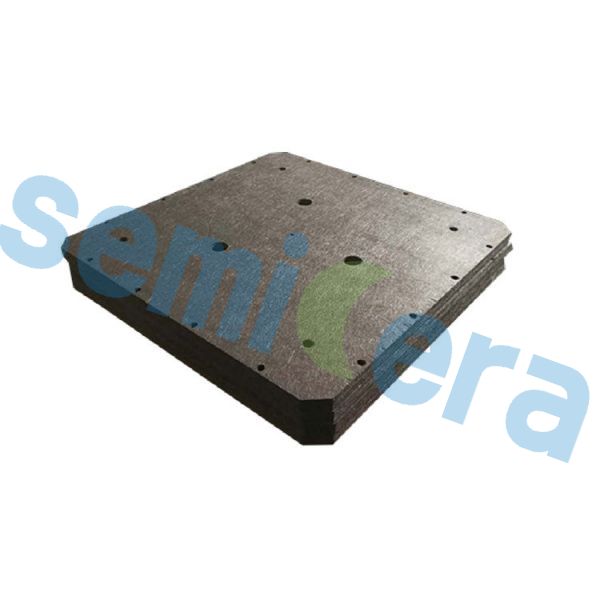

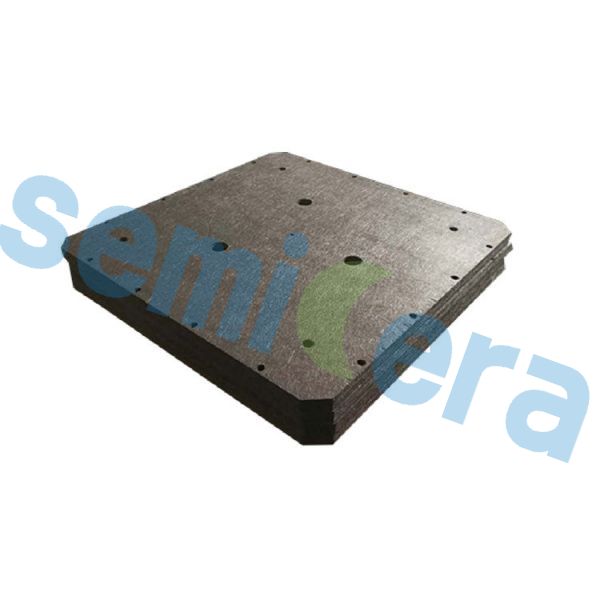

Carbon Fiber Felt, C / C Composites

-

Graphite Insulation Felt, Carbon Hard Felt bakeng sa ...

-

Silicon carbide silika e khethehileng e tsoetseng pele ea ceramic ...

-

Zirconia optical fiber ceramic manipulator