Silicon carbide (SiC) thepa e le 'ngoe ea kristale e na le lekhalo le leholo la lekhalo la sehlopha (~ Si makhetlo a 3), conductivity e phahameng ea mocheso (~Si 3.3 linako kapa GaAs makhetlo a 10), tekanyo e phahameng ea ho falla ha elektronike (~ Si 2.5 linako), ho senyeha ho matla ha motlakase tšimo (~ Si 10 linako kapa GaAs 5 linako) le litšobotsi tse ling tse hlaheletseng.

Thepa ea semiconductor ea moloko oa boraro haholo-holo e kenyelletsa SiC, GaN, daemane, joalo-joalo, hobane bophara ba lekhalo la sehlopha sa eona (Mohlala) bo boholo ho feta kapa bo lekana le li-volts tsa 2.3 electron (eV), tse tsejoang hape e le lisebelisoa tse pharaletseng tsa lekhalo la semiconductor. Ha ho bapisoa le lisebelisoa tsa semiconductor tsa moloko oa pele le oa bobeli, lisebelisoa tsa semiconductor tsa moloko oa boraro li na le melemo ea ho tsamaisa mocheso o phahameng, motlakase o senyehang haholo, tekanyo e phahameng ea ho falla ha elektronike le matla a phahameng a ho kopanya, a ka finyellang litlhoko tse ncha tsa theknoloji ea morao-rao ea elektroniki bakeng sa boemo bo phahameng. mocheso, matla a phahameng, khatello e phahameng, maqhubu a phahameng le ho hanyetsa mahlaseli le maemo a mang a thata. E na le litebello tsa bohlokoa tsa ts'ebeliso maemong a ts'ireletso ea naha, sefofane, sefofane, tlhahlobo ea oli, polokelo ea mahlo, joalo-joalo, 'me e ka fokotsa tahlehelo ea matla ka ho feta 50% liindastering tse ngata tsa maano tse kang likhokahano tsa Broadband, matla a letsatsi, tlhahiso ea likoloi, mabone a semiconductor, le marang-rang a bohlale, 'me a ka fokotsa molumo oa thepa ka ho feta 75%, e leng ntho ea bohlokoahali bakeng sa nts'etsopele ea mahlale a batho le thekenoloji.

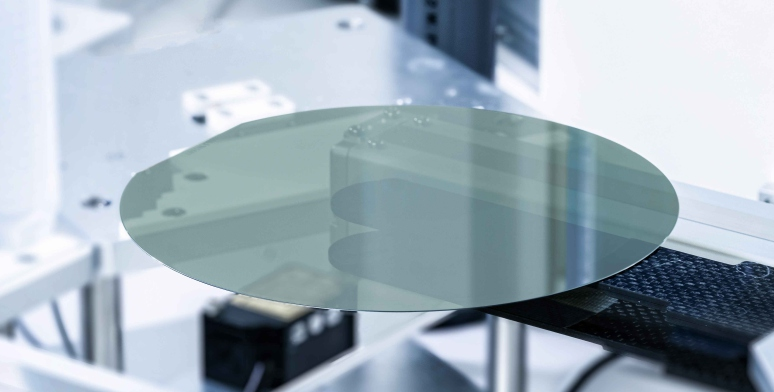

Matla a Semicera a ka fana ka bareki ba boleng bo phahameng ba Conductive (Conductive), Semi-insulating (Semi-insulating), HPSI (High Purity semi-insulating) silicon carbide substrate; Ho phaella moo, re ka fana ka bareki ba nang le homogeneous le heterogeneous silicon carbide epitaxial sheets; Re ka boela ra iketsetsa leqephe la epitaxial ho latela litlhoko tse khethehileng tsa bareki, 'me ha ho na palo e fokolang ea taelo.

LIEKETSENG TSIETSO

*n-Pm=n-mofuta oa Pm-Grade,n-Ps=n-type Ps-Grade,Sl=Semi-lnsulation

| Ntho | 8-Intshi | 6-Intshi | 4-Intshi | ||

| nP | n-Pm | n-Pes | SI | SI | |

| TTV(GBIR) | ≤6um | ≤6um | |||

| Bow(GF3YFCD)-Boleng bo Felletseng | ≤15μm | ≤15μm | ≤25μm | ≤15μm | |

| Warp(GF3YFER) | ≤25μm | ≤25μm | ≤40μm | ≤25μm | |

| LTV(SBIR) -10mmx10mm | <2μm | ||||

| Wafer Edge | Beveling | ||||

SEBAKA PHETHA

*n-Pm=n-type Pm-Grade,n-Ps=n-type Ps-Grade,Sl=Semi-Insulating

| Ntho | 8-Intshi | 6-Intshi | 4-Intshi | ||

| nP | n-Pm | n-Pes | SI | SI | |

| Surface Finish | Mahlakore a mabeli a Optical Polish, Si- Face CMP | ||||

| SurfaceRoughness | (10um x 10um) Si-FaceRa≤0.2nm C-Face Ra≤ 0.5nm | (5umx5um) Si-Face Ra≤0.2nm C-Face Ra≤0.5nm | |||

| Li-Chips tsa Edge | Ha ho e dumellwe (bolelele le bophara≥0.5mm) | ||||

| Li-indent | Ha ho le e 'ngoe e Lumelloang | ||||

| Scratches(Si-Face) | Kty.≤5, Kakaretso Bolelele≤0.5× bophara ba wafer | Kty.≤5, Kakaretso Bolelele≤0.5× bophara ba wafer | Kty.≤5, Kakaretso Bolelele≤0.5× bophara ba wafer | ||

| Mapetso | Ha ho le e 'ngoe e Lumelloang | ||||

| Kenyelletso ea Edge | 3mm | ||||