Ho fumana khotsofalo ea bareki ke sepheo sa k'hamphani ea rona bakeng sa se molemo. Re tla etsa matsapa a matle a ho theha litharollo tse ncha le tsa boleng bo holimo, re phethe lintlha tsa hau tse ikhethileng, 'me re u fe litšebeletso tse rekisoang esale pele, tse rekisoang le tsa morao-rao bakeng sa theolelo e kholo ea Theko e tlase ea Green/Black Silicon Carbide Use for polishing. , Bareki ba rona ba ajoa haholo ha ba le Amerika Leboea, Afrika le Europe Bochabela. re khona ho fana ka thepa ea boleng bo holimo ka boleng bohle ba tlholisano.

Ho fumana khotsofalo ea bareki ke sepheo sa k'hamphani ea rona bakeng sa se molemo. Re tla etsa matsapa a matle a ho theha litharollo tse ncha le tsa boleng bo holimo, ho phethahatsa lintlha tsa hau tse ikhethileng le ho u fa litšebeletso tsa pele ho thekiso, thekisong le kamora ho rekisoaChina Silicon Carbide le Sic, Re sebelisa lisebelisoa tse tsoetseng pele tsa tlhahiso le theknoloji, le lisebelisoa tse phethahetseng tsa tlhahlobo le mekhoa ea ho netefatsa boleng ba sehlahisoa sa rona. Ka litalenta tsa rona tsa maemo a holimo, taolo ea mahlale, lihlopha tse khabane, le ts'ebeletso e hlokolosi, lihlahisoa tsa rona li ratoa ke bareki ba malapeng le ba kantle ho naha. Ka tšehetso ea hau, re tla haha hosane e ntle!

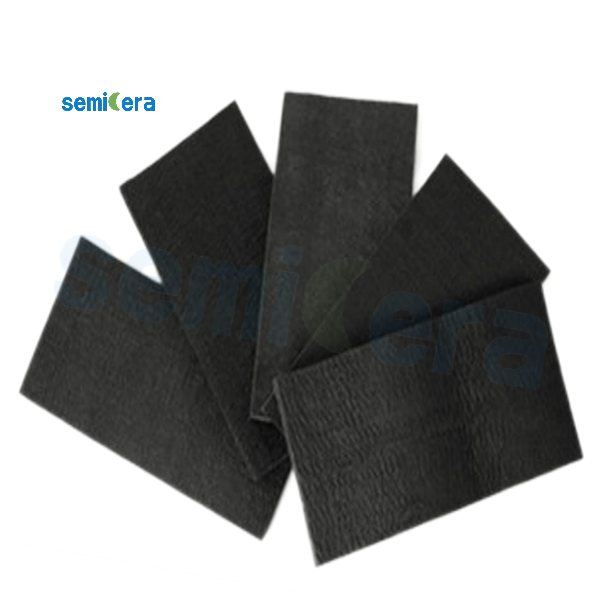

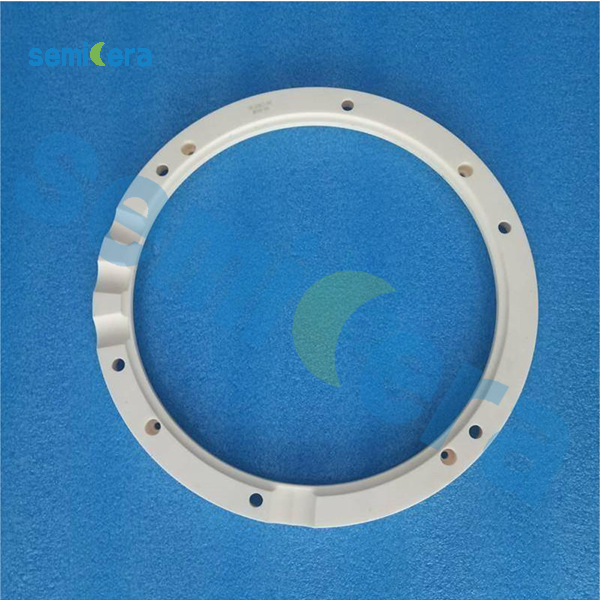

Silicone graphite ke thepa e kopantsoeng eo silicon carbide e khomaretsoeng holim'a karoloana ea graphite. E na le litšoaneleho tsa boima bo phahameng, matla a phahameng a mochine le ho hanyetsa ha silicon carbide, hammoho le thepa ea ho itlotsa le ho hanyetsa mocheso oa graphite. Ke thepa e loketseng ea likhohlano le thepa e tiisang mochini, e loketseng ho tiisa lipompo tse fapaneng tsa metsi, lipompo tsa oli, lipompo tsa lik'hemik'hale, le li-bearings tsa lipompo tse fapaneng tse lebelo le tse phahameng haholo. Ntle le moo, graphite e entsoeng ka siliconized e na le khanyetso e ntle ea oxidation, ho hanyetsa mocheso oa mocheso, porosity e tlase, le conductivity e itseng ea motlakase, 'me e ka sebelisoa e le lisebelisoa tse kang litšepe tse qhibilihisang tšepe le li-tubes tse ntseng li sebelisoa.

Sebopeho sa siliconized graphite se tšoana, bokaholimo bo lumellana le ka hare, 'me tekanyo ea sebopeho sa silicon carbide le graphite e ka fetoha. Ha litaba tsa silicon carbide li phahame, ho ba le letsoalo le leholo la thepa, matla a khatello a phahama, 'me resistivity e eketseha.

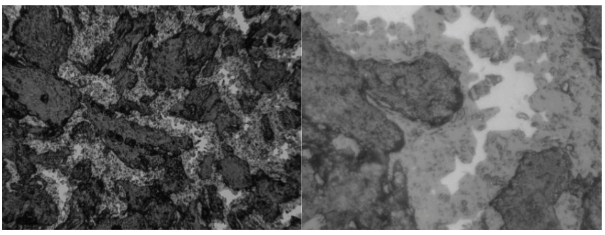

Setšoantšo sa metallographic sa graphite ea siliconized

(karolo e ntšo ke graphite, karolo e bohlooho ke silicon carbide, 'me karolo e tšoeu ke silicon)

| 硅化石墨主要技术指标 | |

| 类别 Ntho | 指标 Value |

| 密度 Density | 2.4-2.9g/cm³ |

| 孔隙率 Porosity | <0.5% |

| 抗压强度 Matla a hatellang | > 400MPa |

| 抗折强度 Flexural matla Matla a flexural | > 120MPa |

| 热导率 Thermal conductivity | 120W/mK |

| 热膨胀系数 Coefficient ea katoloso ea mocheso | 4.5×10-6 |

| 弹性模量Modulus ea matla | 120GPa |

| 冲击强度 Matla a amang | 1.9KJ/m² |

| 水润滑摩擦系数 Metsi a lubricated friction | 0.005 |

| 干摩擦系数Dry friction coefficient | 0.05 |

| 化学稳定性 Ho tsitsa ha lik'hemik'hale | 各种盐,有机溶剂,强酸(HF,HCl,H₂SO4,HNO₃) Matsoai a fapa-fapaneng, li-solvents, li-acid tse matla (HF,HCl,H₂SO4,HNO₃) |

| 长期稳定使用温度 Mocheso oa tšebeliso ea nako e telele o tsitsitseng | 800℃(氧化气氛), 2300℃(惰性或真空气氛) 800 ℃ (sepakapaka se oxidizing), 2300 ℃ (sepakapaka sa inert kapa vacuum) |

| 电阻率 Motlakase oa ho hanyetsa | 120×10-6Ωm |

Ho fumana khotsofalo ea bareki ke sepheo sa k'hamphani ea rona bakeng sa se molemo. Re tla etsa matsapa a matle a ho theha litharollo tse ncha le tsa boleng bo holimo, re phethe lintlha tsa hau tse ikhethileng, 'me re u fe litšebeletso tse rekisoang esale pele, tse rekisoang le tsa morao-rao bakeng sa theolelo e kholo ea Theko e tlase ea Green/Black Silicon Carbide Use for polishing. , Bareki ba rona ba ajoa haholo ha ba le Amerika Leboea, Afrika le Europe Bochabela. re khona ho fana ka thepa ea boleng bo holimo ka boleng bohle ba tlholisano.

Theko e kholoChina Silicon Carbide le Sic, Re sebelisa lisebelisoa tse tsoetseng pele tsa tlhahiso le theknoloji, le lisebelisoa tse phethahetseng tsa tlhahlobo le mekhoa ea ho netefatsa boleng ba sehlahisoa sa rona. Ka litalenta tsa rona tsa maemo a holimo, taolo ea mahlale, lihlopha tse khabane, le ts'ebeletso e hlokolosi, lihlahisoa tsa rona li ratoa ke bareki ba malapeng le ba kantle ho naha. Ka tšehetso ea hau, re tla haha hosane e ntle!

-

Theko e kholo ea China Supplier Soft Quick Absor...

-

Theko ea Tlholisano bakeng sa Industrial High-Temperatu...

-

OEM Manufacturer China Factory Price Precision ...

-

China Supplier Dual Air Inlet Venturi Silicon C...

-

Theko e tlase Factory Price Custom Industr...

-

Setaele sa Europe bakeng sa Karabelo ea Phepelo ea Factory Direct...