Tlhaloso

Li-ceramics tsa silicon carbide li na le thepa e ntle ea mochini mocheso oa kamore, joalo ka matla a phahameng, boima bo phahameng, modulus e phahameng, joalo-joalo, e boetse e na le botsitso bo phahameng ba mocheso joalo ka conductivity e phahameng ea mocheso, coefficient e tlase ea katoloso ea mocheso, le ho satalla ho itseng hantle. tshebetso ya ho sebetsa.

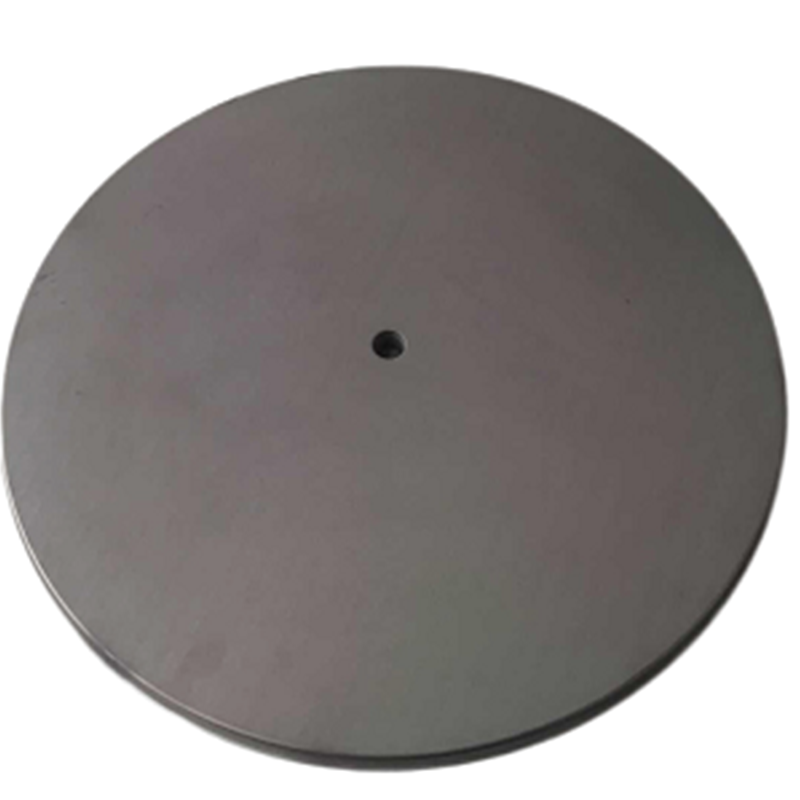

Li loketse ka ho khetheha bakeng sa ho hlahisa likarolo tse nepahetseng tsa ceramic bakeng sa lisebelisoa tse kopantsoeng tsa potoloho tse kang mechine ea lithography, haholo-holo e sebelisetsoang ho etsa sepalangoang sa SiC / susceptor, sekepe sa SiC wafer, disc e anyang, poleiti e pholileng ea metsi, sehlahlo se nepahetseng sa ho lekanya, grating le likarolo tse ling tsa sebopeho sa ceramic.

Melemo

Ho hanyetsa mocheso o phahameng: tšebeliso e tloaelehileng ho 1800 ℃

High thermal conductivity: e lekanang le thepa ea graphite

Boima bo phahameng: ho thatafala ha bobeli ho latela taemane, boron nitride

Ho hanyetsa kutu: acid e matla le alkali ha e na kutu ho eona, ho hanyetsa kutu ho molemo ho feta tungsten carbide le alumina.

Boima bo bobebe: boima bo tlase, bo haufi le aluminium

Ha ho na deformation: coefficient e tlase ea katoloso ea mocheso

Thermal shock resistance: e khona ho mamella liphetoho tse matla tsa mocheso, e hanela ho sisinyeha ha mocheso, 'me e na le ts'ebetso e tsitsitseng

Silicon carbide carrier tse kang sic etching carrier, ICP etching susceptor, li sebelisoa haholo ho semiconductor CVD, vacuum sputtering joalo-joalo Re ka fa bareki ba nang le li-wafer carriers tsa silicon le lisebelisoa tsa silicon carbide ho kopana le likopo tse fapaneng.

Melemo

| Thepa | Boleng | Mokhoa |

| Botenya | 3.21 g/cc | Sink-float le dimension |

| Mocheso o khethehileng | 0.66 J/g °K | Pulsed laser flash |

| Matla a flexural | 450 MPa560 MPa | 4 ntlha e kobehang, RT4 ntlha e kobehang, 1300 ° |

| Ho robeha ho thata | 2,94 MPa m1/2 | Microindentation |

| Ho thatafala | 2800 | Vicker's, boima ba 500g |

| Elastic ModulusYoung's Modulus | 450 GPA430 GPA | 4 pt koba, RT4 pt kobeha, 1300 °C |

| Boholo ba lijo-thollo | 2 - 10 µm | SEM |

Boemo ba Khoebo

WeiTai Energy Technology Co., Ltd. ke mofani oa thepa ea ka sehloohong oa li-ceramics tse tsoetseng pele tsa semiconductor le moetsi feela Chaena ea ka fanang ka lisebelisoa tse phahameng tsa silicon carbide ceramic (haholo-holo Recrystallized SiC) le CVD SiC coating. Ho feta moo, k'hamphani ea rona e boetse e ikemiselitse ho etsa masimo a ceramic a kang alumina, aluminium nitride, zirconia, le silicon nitride, joalo-joalo.

Lihlahisoa tsa rona tsa mantlha li kenyelletsa: silicon carbide etching disc, silicon carbide boat tow, silicon carbide wafer boat (Photovoltaic&Semiconductor), silicon carbide furnace tube, silicon carbide cantilever paddle, silicon carbide chucks, silicon carbide beam, hammoho le CVD SiC coating le TaC. ho roala. Lihlahisoa tse sebelisoang haholo indastering ea semiconductor le photovoltaic, joalo ka lisebelisoa tsa kholo ea kristale, epitaxy, etching, ho paka, ho roala le libono tsa phallo, jj.

Lipalangoang

-

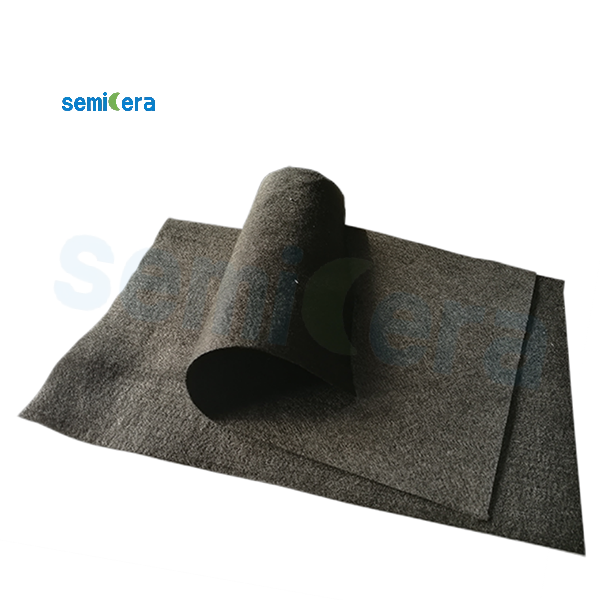

Supply ODM Soft Carbon Felt Graphite Felt for S...

-

Setsebi sa China Sic Cantilever Paddles Silic...

-

ODM Supplier High Temperature Insulating Cerami...

-

China wholesale Carbon Roller Thermal Insulatio...

-

China Supplier Factory Price Custom Indasteri ...

-

Khetho e Khōlō ea Lesela la Carbon Fiber Lesela la Khabone...