Thepa ea recrystallized silicon carbide

Recrystallized silicon carbide (R-SiC) ke sesebelisoa se sebetsang hantle se nang le boima ba bobeli ho daemane, se entsoeng ka mocheso o phahameng ka holimo ho 2000 ℃. E na le lisebelisoa tse ngata tse ntle tsa SiC, joalo ka matla a mocheso o phahameng, khanyetso e matla ea kutu, khanyetso e ntle ea oxidation, ho hanyetsa mocheso o motle joalo-joalo.

● Mekhoa e metle ea ho sebetsa. Recrystallized silicon carbide e na le matla a phahameng le ho satalla ho feta carbon fiber, khanyetso e matla, e ka bapala ts'ebetso e ntle maemong a mocheso o feteletseng, e ka bapala ts'ebetso e ntle ea ho hanyetsa maemong a fapaneng. Ho phaella moo, e boetse e na le ho feto-fetoha ha maemo hantle 'me ha e senyehe habonolo ka ho otlolla le ho koba, e leng ho ntlafatsang haholo ts'ebetso ea eona.

● Ho hanyetsa ho bola ho hoholo. Recrystallized silicon carbide e na le khanyetso e phahameng ea kutu ho mefuta e fapaneng ea mecha ea litaba, e ka thibela khoholeho ea mefuta e mengata ea mecha ea phatlalatso e senyang, e ka boloka thepa ea eona ea mechine ka nako e telele, e na le ho khomarela ka matla, e le hore e be le bophelo bo bolelele ba tšebeletso. Ho phaella moo, e boetse e na le botsitso bo botle ba mocheso, e ka ikamahanya le mefuta e itseng ea liphetoho tsa mocheso, e ntlafatsa phello ea eona ea kopo.

● Sintering ha e fokotsehe. Hobane ts'ebetso ea sintering ha e fokotsehe, ha ho khatello e setseng e tla baka deformation kapa ho phunyeha ha sehlahisoa, 'me likarolo tse nang le libopeho tse rarahaneng le ho nepahala ho phahameng li ka lokisoa.

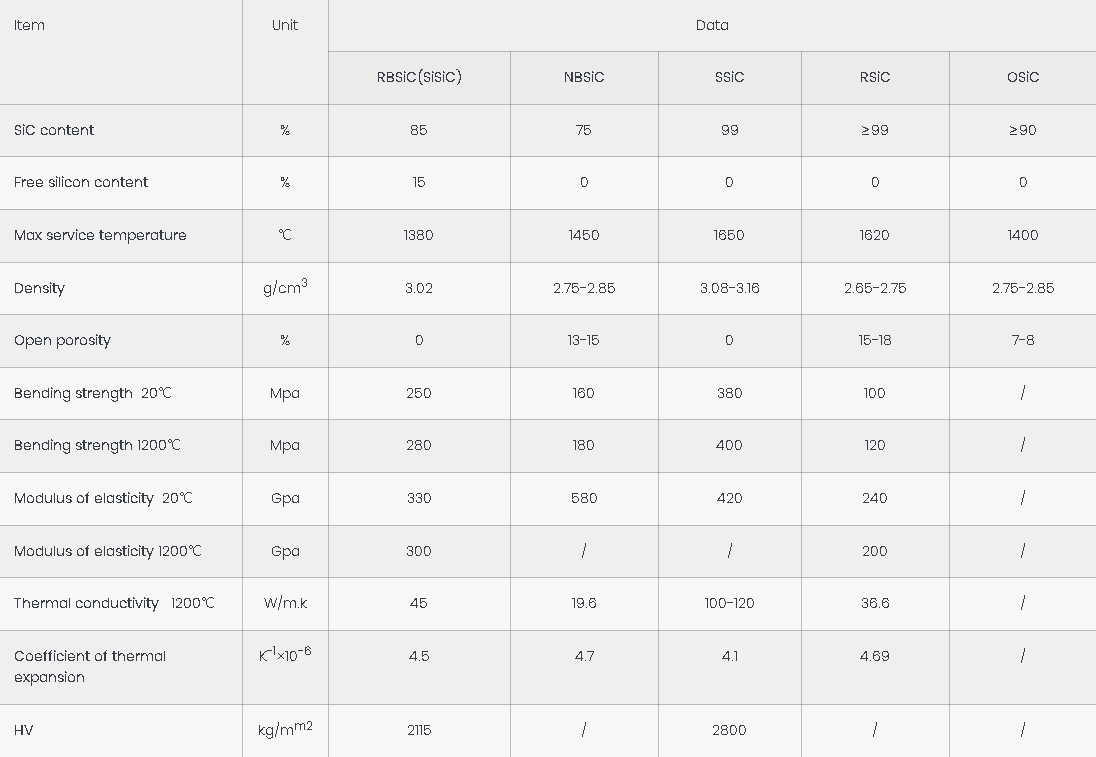

Litekanyetso tsa Tekheniki:

Lethathamo la Boitsebiso

| 材料Material | R-SiC |

| 使用温度Mocheso o sebetsang (°C) | 1600°C (氧化气氛Tikoloho ea oxidizing) 1700°C (还原气氛Ho fokotsa tikoloho) |

| SiC含量Likahare tsa SiC (%) | > 99 |

| 自由Si含量Likahare tsa Si mahala (%) | <0.1 |

| 体积密度Boima ba bongata (g/cm3) | 2.60-2,70 |

| 气孔率Ho bonahala porosity (%) | <16 |

| 抗压强度Matla a sithabetsang (MPa) | > 600 |

| 常温抗弯强度Matla a ho kobeha a batang (MPa) | 80-90 (20°C) |

| 高温抗弯强度Matla a ho kobeha a chesang (MPa) | 90-100 (1400°C) |

| 热膨胀系数 Coefficient ea ho eketsa mocheso @1500°C (10-6/°C) | 4.70 |

| 导热系数Thermal conductivity @1200°C (W/m•K) | 23 |

| 杨氏模量Elastic modulus (GPA) | 240 |

| 抗热震性Ho hanyetsa mocheso oa mocheso | 很好E ntle haholo |

-

China Mofani oa Silicon Carbide Sic Spray Nozzle

-

Silicon e sa tsoa Fihla Boima bo Botlaaseng bo Kentsoeng hape...

-

100% Original Insulation Material Heat Resistan...

-

OEM Customized Silicon Carbide Heater Sic Heati...

-

Factory wholesale China Customized Different Si...

-

Ho rekisoa ho Chesang bakeng sa Nako e Phahameng ea Khoebo ea Liindasteri...