Melemo

Ho hanyetsa mocheso o phahameng oa oxidation

E babatsehang Corrosion resistance

Khahlano e ntle ea Abrasion

High coefficient ea mocheso conductivity

Ho itšehla thajana, boima bo tlase

Boima bo phahameng

Moralo o hlophisitsoeng.

Lisebelisoa

- Tšimo e hananang le ho roala: sehlahla, poleiti, nozzle ea sandblasting, lesela la leholiotsoana, moqomo oa ho sila, joalo-joalo ...

-High Temperature Field: siC Slab, Quenching Furnace Tube, Radiant Tube,crucible, Heating Element, Roller, Beam, Heat Exchanger, Cold Air Pipe, Burner Nozzle, Thermocouple Protection Tube, SiC sekepe, Kiln car Structure, Setter, joalo-joalo.

-Silicon Carbide Semiconductor: Seketsoana sa SiC wafer, sic chuck, sic paddle, sic cassette, sic diffusion tube, wafer fork, suction plate, guideway, joalo-joalo.

-Silicon Carbide Seal Field: mefuta eohle ea selikalikoe sa ho tiisa, ho beha, ho bushing, joalo-joalo.

-Photovoltaic Field: Cantilever Paddle, Grinding Barrel, Silicon Carbide Roller, joalo-joalo.

- Tšimo ea betri ea lithium

Thepa ea 'Mele ea SiC

| Thepa | Boleng | Mokhoa |

| Botenya | 3.21 g/cc | Sink-float le dimension |

| Mocheso o khethehileng | 0.66 J/g °K | Pulsed laser flash |

| Matla a flexural | 450 MPa560 MPa | 4 ntlha e kobehang, RT4 ntlha e kobehang, 1300 ° |

| Ho robeha ho thata | 2,94 MPa m1/2 | Microindentation |

| Ho thatafala | 2800 | Vicker's, boima ba 500g |

| Elastic ModulusYoung's Modulus | 450 GPA430 GPA | 4 pt koba, RT4 pt kobeha, 1300 °C |

| Boholo ba lijo-thollo | 2 - 10 µm | SEM |

Thermal Properties of SiC

| Thermal Conductivity | 250 W/m °K | Mokhoa oa laser flash, RT |

| Katoloso ea Thermal (CTE) | 4.5 x 10-6 °K | Mocheso oa kamore ho fihlela ho 950 °C, dilatometer ea silika |

Tekheniki Parameters

| Ntho | Yuniti | Lintlha | ||||

| RBSiC(SiSiC) | NBSiC | SSiC | RSiC | OSiC | ||

| Likahare tsa SiC | % | 85 | 75 | 99 | 99.9 | ≥99 |

| Likahare tsa silicon mahala | % | 15 | 0 | 0 | 0 | 0 |

| Mocheso o moholo oa tšebeletso | ℃ | 1380 | 1450 | 1650 | 1620 | 1400 |

| Botenya | g/cm3 | 3.02 | 2.75-2,85 | 3.08-3.16 | 2.65-2,75 | 2.75-2,85 |

| Porosity e bulehileng | % | 0 | 13-15 | 0 | 15-18 | 7-8 |

| Matla a ho koba 20 ℃ | 'Mpa | 250 | 160 | 380 | 100 | / |

| Matla a ho koba 1200 ℃ | 'Mpa | 280 | 180 | 400 | 120 | / |

| Modulus ea elasticity 20 ℃ | GPA | 330 | 580 | 420 | 240 | / |

| Modulus ea elasticity 1200 ℃ | GPA | 300 | / | / | 200 | / |

| Thermal conductivity 1200 ℃ | W/mK | 45 | 19.6 | 100-120 | 36.6 | / |

| Coefficient ea katoloso ea mocheso | K-1X10-6 | 4.5 | 4.7 | 4.1 | 4.69 | / |

| HV | Kg/mm2 | 2115 | / | 2800 | / | / |

CVD silicon carbide coating holim'a bokantle ba silicon carbide ceramic dihlahiswa ka fihla bohloeki ho feta 99.9999% ho finyella litlhoko tsa bareki ka indasteri semiconductor.

-

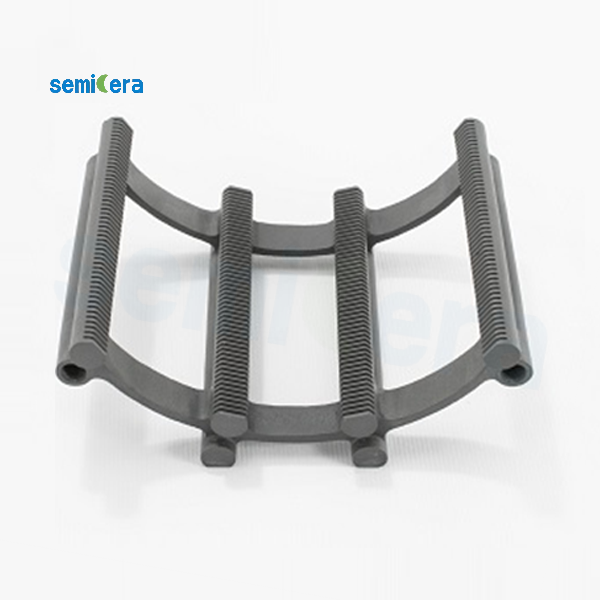

Moralo oa Litsebi Sic Cantilever Paddles Sili...

-

Setifikeiti sa IOS Se Setifikeiti sa Ngoana se Lohiloeng sa Cotton Quilt ...

-

Lesale la Tantalum Carbide (TaC) le koahetsoeng

-

Fektheri e rekisoang ka ho chesa Black Sic Silicon Carbide...

-

Feme ea Pele e Itseng Shaft Seal Ring Sil...

-

Sampole ea Mahala bakeng sa Lihlahisoa tsa Mofuta o Khethehileng oa Sic habeli...