Hona joale, moloko oa boraro oa li-semiconductors o laoloa kesilicon carbide. Sebopeho sa litšenyehelo tsa lisebelisoa tsa eona, substrate e ikarabella bakeng sa 47%, 'me epitaxy e nka 23%. Tse peli hammoho li ikarabella hoo e ka bang 70%, e leng karolo ea bohlokoa ka ho fetisisa easilicon carbideketane ea indasteri ea tlhahiso ea lisebelisoa.

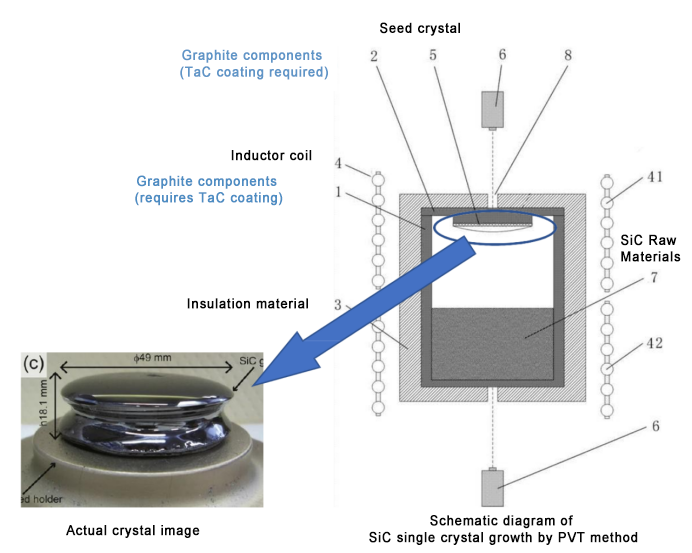

Mokhoa o sebelisoang hangata oa ho lokisasilicon carbidekristale e le 'ngoe ke mokhoa oa PVT ('mele oa ho tsamaisa mouoane). Molao-motheo ke ho etsa lisebelisoa tse tala sebakeng se phahameng sa mocheso le kristale ea peo sebakeng se batlang se le tlaase. Lisebelisoa tse tala ka mocheso o phahameng li senyeha 'me ka ho toba li hlahisa lintho tsa mohato oa khase ntle le mokelikeli. Lintho tsena tsa khase ea khase li isoa kristale ea peo tlas'a koloi ea mocheso oa mocheso oa axial, 'me li na le nucleate le ho hōla kristale ea peo ho etsa silicon carbide single crystal. Hona joale, lik'hamphani tse tsoang linaheng tse ling tse kang Cree, II-VI, SiCrystal, Dow le lik'hamphani tsa malapeng tse kang Tianyue Advanced, Tianke Heda, le Century Golden Core kaofela li sebelisa mokhoa ona.

Ho na le mefuta e fetang 200 ea kristale ea silicon carbide, 'me ho hlokahala taolo e nepahetseng haholo ho hlahisa foromo e hlokahalang ea kristale e le' ngoe (e tloaelehileng ke mofuta oa kristale oa 4H). Ho ea ka prospectus ea Tianyue Advanced, lihlahisoa tsa kristale tsa k'hamphani ka 2018-2020 le H1 2021 e ne e le 41%, 38.57%, 50.73% le 49.90% ka ho latellana, 'me lihlahisoa tsa substrate e ne e le 72.61%, 5, 7%, 7, 7, 7, 7, 5, 7, 7. ka ho latellana. Kotulo e akaretsang ha joale ke 37.7% feela. Ho nka mohlala oa mokhoa o tloaelehileng oa PVT, kotulo e tlase e bakoa haholo ke mathata a latelang a ho lokisa karoloana ea SiC:

1. Bothata ba taolo ea tšimo ea mocheso: Lithupa tsa kristale tsa SiC li hloka ho hlahisoa ka mocheso o phahameng oa 2500 ℃, ha likristale tsa silicon li hloka 1500 ℃ feela, kahoo ho hlokahala libōpi tse khethehileng tsa kristale, 'me mocheso oa kholo o hloka ho laoloa hantle nakong ea tlhahiso. , eo ho leng thata haholo ho e laola.

2. Lebelo le butle la tlhahiso: Sekhahla sa khōlo ea thepa ea silicon e tloaelehileng ke 300 mm ka hora, empa likristale tse le 'ngoe tsa silicon carbide li ka hōla li-microns tse 400 ka hora, e leng hoo e ka bang ka makhetlo a 800 ho fapana.

3. Litlhoko tse phahameng bakeng sa lihlahisoa tse ntle tsa lihlahisoa, 'me lihlahisoa tsa lebokose le letšo li thata ho li laola ka nako: Mekhahlelo ea mantlha ea li-wafers tsa SiC li kenyelletsa ho teteana ha microtube, density density, resistivity, warpage, top roughness, joalo-joalo Nakong ea ts'ebetso ea ho hōla ha kristale, ho joalo. e hlokahalang ho laola ka nepo likarolo tse kang karo-karolelano ea silicon-khabone, sekhahla sa mocheso oa kholo, sekhahla sa kholo ea kristale, le khatello ea phallo ea moea. Ho seng joalo, li-polymorphic inclusions li ka 'na tsa etsahala, tse hlahisang likristale tse sa tšoaneleheng. Ka lebokoseng le letšo la graphite crucible, ho ke ke ha khoneha ho bona boemo ba ho hōla ha kristale ka nako ea sebele, 'me ho hlokahala taolo e nepahetseng ea tšimo ea mocheso, ho bapisa thepa le ho bokella phihlelo.

4. Bothata ba ho atolosoa ha kristale: Tlas'a mokhoa oa ho tsamaisa khase ea khase, theknoloji ea katoloso ea kholo ea kristale ea SiC e thata haholo. Ha boholo ba kristale bo ntse bo eketseha, bothata ba eona ba kholo bo eketseha haholo.

5. Ka kakaretso lihlahisoa tse fokolang: Sehlahisoa se tlaase haholo-holo se entsoe ka li-link tse peli: (1) Crystal rod chai = semiconductor-grade crystal rod output / (semiconductor-grade crystal rod output + non-semiconductor-grade crystal rod output) × 100%; (2) Sehlahisoa sa substrate = qualified substrate output/(qualified substrate output + unqualified substrate output) × 100%.

Tokisetsong ea boleng bo phahameng le chai e ngatalikaroloana tsa silicon carbide, motheo o hloka lisebelisoa tse molemo tsa tšimo ea mocheso ho laola ka nepo mocheso oa tlhahiso. Thermal field crucible kits e sebelisoang hajoale haholo-holo likarolo tsa sebopeho sa graphite tse hloekileng haholo, tse sebelisetsoang ho futhumatsa le ho qhibilihisa phofo ea carbon le phofo ea silicon le ho futhumala. Lisebelisoa tsa graphite li na le litšoaneleho tsa matla a phahameng a khethehileng le modulus e khethehileng, ho hanyetsa mocheso o motle oa mocheso le ho hanyetsa ho bola, empa li na le mefokolo ea ho ba oxidized habonolo libakeng tsa mocheso o phahameng oa oksijene, ha li hanyetsane le ammonia, le ho hanyetsa mongoapo hampe. Ts'ebetsong ea silicon carbide kholo ea kristale e le 'ngoe lesilicon carbide epitaxial wafertlhahiso, ho thata ho finyella litlhoko tsa batho tse ntseng li eketseha tse thata bakeng sa tšebeliso ea thepa ea graphite, e thibelang ka botebo tsoelo-pele ea eona le tšebeliso e sebetsang. Ka hona, liphahlo tse phahameng tsa mocheso tse kang tantalum carbide li se li qalile ho hlaha.

2. Litšobotsi tsaTantalum Carbide Coating

TaC ceramic e na le ntlha e qhibilihang e fihlang ho 3880 ℃, boima bo phahameng (Mohs hardness 9-10), conductivity e kholo ea mocheso (22W · m-1 · K−1), matla a maholo a ho koba (340-400MPa), le katoloso e nyenyane ea mocheso. coefficient (6.6×10−6K−1), 'me e bonts'a botsitso bo botle ba thermochemical le thepa e ntle ea 'mele. E na le lik'hemik'hale tse ntle tsa lik'hemik'hale le ho lumellana le mechine le lisebelisoa tsa graphite le C / C tse kopantsoeng. Ka hona, ho roala ha TaC ho sebelisoa haholo ts'ireletso ea mocheso oa sefofane, kholo ea kristale e le 'ngoe, lisebelisoa tsa elektroniki tsa matla le lisebelisoa tsa bongaka.

TaC e koahetsoenggraphite e na le khanyetso e ntle ea lik'hemik'hale ho feta graphite e se nang letho kapa graphite e koahetsoeng ke SiC, e ka sebelisoa ka mokhoa o tsitsitseng mocheso o phahameng oa 2600 °, 'me ha e sebetsane le likarolo tse ngata tsa tšepe. Ke kobo e ntle ka ho fetisisa molokong oa boraro oa kholo ea kristale e le 'ngoe ea semiconductor le maemo a ts'oarellang. E ka ntlafatsa haholo taolo ea mocheso le litšila ts'ebetsong le ho itokisetsaliphaphatha tsa silicon carbide tsa boleng bo holimole tse amanangliphaphatha tsa epitaxial. E loketse ka ho khetheha bakeng sa ho hōlisa GaN kapa AlN e le 'ngoe ea likristale tse nang le lisebelisoa tsa MOCVD le ho hōla likristale tsa SiC tse nang le lisebelisoa tsa PVT,' me boleng ba likristale tse seng li hōlile li ntlafatsoa haholo.

III. Melemo ea Tantalum Carbide Coated Devices

Tšebeliso ea Tantalum Carbide TaC coating e ka rarolla bothata ba bofokoli ba kristale le ho ntlafatsa boleng ba kholo ea kristale. Ke e 'ngoe ea litataiso tsa mantlha tsa "ho hola ka potlako, ho hola ka botenya le ho hola halelele". Patlisiso ea indasteri e boetse e bonts'itse hore Tantalum Carbide Coated Graphite Crucible e ka fihlela mocheso o ts'oanang haholoanyane, ka hona e fana ka taolo e ntle ea ts'ebetso bakeng sa kholo ea kristale e le 'ngoe ea SiC, ka hona e fokotsa haholo monyetla oa ho theha polycrystalline pheletsong ea likristale tsa SiC. Ntle le moo, Tantalum Carbide Graphite Coating e na le melemo e 'meli e meholo:

(I) Ho fokotsa Litšitiso tsa SiC

Mabapi le ho laola liphoso tsa kristale e le 'ngoe ea SiC, hangata ho na le mekhoa e meraro ea bohlokoa. Ntle le ho ntlafatsa mekhoa ea ho hōla le lisebelisoa tsa boleng bo phahameng ba mohloli (joaloka SiC mohloli oa phofo), ho sebelisa Tantalum Carbide Coated Graphite Crucible e ka boela ea finyella boleng bo botle ba kristale.

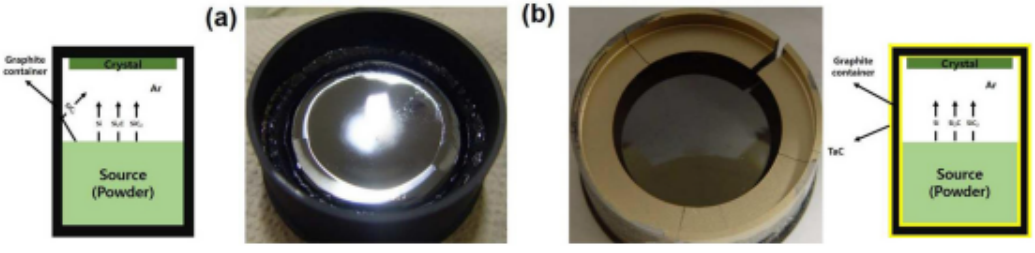

Sets'oants'o sa sebopeho sa graphite crucible (a) le TAC coated crucible (b)

Ho ea ka lipatlisiso tse entsoeng ke Univesithi ea Europe Bochabela ea Korea, ho se hloeke ho ka sehloohong ho SiC crystal kgolo ke naetrojene, 'me tantalum carbide coated graphite crucibles e ka fokotsa ho kenngoa ha naetrojene ea likristale tsa SiC, ka tsela eo ho fokotsa moloko oa likoli tse kang micropipes le ho ntlafatsa kristale. boleng. Liphuputso li bontšitse hore tlas'a maemo a tšoanang, likhahla tsa li-carriers tsa SiC wafers tse hōlileng ka li-crucibles tse tloaelehileng tsa graphite le li-crucibles tse koahetsoeng ke TAC li batla li le 4.5 × 1017 / cm le 7.6 × 1015 / cm, ka ho latellana.

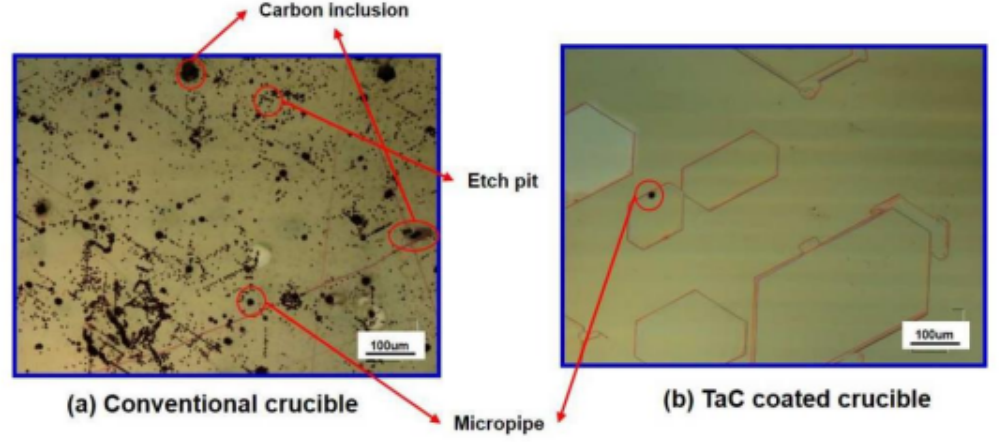

Papiso ea bofokoli ho likristale tse le 'ngoe tsa SiC tse hōlileng ka li-crucibles tse tloaelehileng tsa graphite (a) le li-crucibles tse koahetsoeng ke TAC (b)

(II) Ho ntlafatsa bophelo ba li-crucible tsa graphite

Hona joale, litšenyehelo tsa likristale tsa SiC li ntse li le holimo, tseo litšenyehelo tsa lisebelisoa tsa graphite li etsang hoo e ka bang 30%. Senotlolo sa ho fokotsa litšenyehelo tsa lisebelisoa tsa graphite ke ho eketsa bophelo ba eona ba tšebeletso. Ho ea ka boitsebiso bo tsoang ho sehlopha sa lipatlisiso sa Brithani, liaparo tsa tantalum carbide li ka eketsa bophelo ba tšebeletso ea likarolo tsa graphite ka 30-50%. Ho ea ka palo ena, feela ho nkela sebaka sa tantalum carbide coated graphite ho ka fokotsa litšenyehelo tsa likristale tsa SiC ka 9% -15%.

4. Mokhoa oa ho lokisetsa ho roala ha Tantalum carbide

Mekhoa ea ho lokisoa ha TaC e ka aroloa ka mekhahlelo e meraro: mokhoa o tiileng oa mohato, mokhoa oa mohato oa mokelikeli le mokhoa oa khase. Mokhoa o tiileng oa mohato o kenyelletsa haholo mokhoa oa ho fokotsa le mokhoa oa lik'hemik'hale; mokhoa oa mokelikeli oa mohato o kenyelletsa mokhoa oa letsoai o qhibilihisitsoeng, mokhoa oa sol-gel (Sol-Gel), mokhoa oa slurry-sintering, mokhoa oa ho fafatsa ka plasma; mokhoa oa khase ea khase o kenyelletsa ho kenngoa ha mouoane oa lik'hemik'hale (CVD), ho kenngoa ha mouoane oa lik'hemik'hale (CVI) le ho kenngoa ha mouoane oa 'mele (PVD). Mekhoa e fapaneng e na le melemo le mathata a eona. Har'a tsona, CVD ke mokhoa o batlang o holile le o sebelisoang haholo oa ho lokisa liphahlo tsa TaC. Ka ntlafatso e tsoelang pele ea ts'ebetso, lits'ebetso tse ncha tse kang terata e chesang ea mouoane oa lik'hemik'hale le ion beam e thusang lik'hemik'hale tsa mouoane li entsoe.

Lisebelisoa tsa TaC tse fetotsoeng tse thehiloeng ho carbon haholo li kenyelletsa graphite, carbon fiber, le lisebelisoa tsa motsoako oa carbon / carbon. Mekhoa ea ho lokisa liphahlo tsa TaC holim'a graphite e kenyelletsa ho fafatsa ka plasma, CVD, slurry sintering, joalo-joalo.

Melemo ea mokhoa oa CVD: Mokhoa oa CVD oa ho lokisa liphahlo tsa TaC o thehiloe holim'a tantalum halide (TaX5) e le mohloli oa tantalum le hydrocarbon (CnHm) e le mohloli oa carbon. Tlas'a maemo a itseng, li aroloa ho ba Ta le C ka ho latellana, 'me li sebetsana le tse ling ho fumana liphahlo tsa TaC. Mokhoa oa CVD o ka etsoa ka mocheso o tlaase, o ka qobang mefokolo le ho fokotsa thepa ea mechine e bakoang ke ho lokisetsa mocheso o phahameng kapa phekolo ea liphahlo ho isa tekanyong e itseng. Sebopeho le sebopeho sa ho roala lia laoleha, 'me se na le melemo ea bohloeki bo phahameng, boima bo phahameng, le botenya bo tšoanang. Habohlokoa le ho feta, sebopeho le sebopeho sa liphahlo tsa TaC tse lokiselitsoeng ke CVD li ka raloa le ho laoloa habonolo. Ke mokhoa o batlang o holile ebile o sebelisoa haholo bakeng sa ho lokisa liphahlo tsa boleng bo holimo tsa TaC.

Lintlha tse ka sehloohong tse susumetsang ts'ebetso li kenyelletsa:

A. Sekhahla sa phallo ea khase (mohloli oa tantalum, khase ea hydrocarbon e le mohloli oa khabone, khase e tsamaisang thepa, khase ea dilution Ar2, e fokotsang khase H2): Phetoho ea sekhahla sa phallo ea khase e na le tšusumetso e kholo sebakeng sa mocheso, sebaka sa khatello, le sebaka sa phallo ea khase ho kamore ea karabelo, e bakang liphetoho sebopeho, sebopeho le ts'ebetso ea ho roala. Ho eketsa sekhahla sa phallo ea Ar ho tla liehisa sekhahla sa kholo ea ho roala le ho fokotsa boholo ba lijo-thollo, ha tekanyo ea molar mass ea TaCl5, H2, le C3H6 e ama sebopeho sa ho roala. Karolelano ea molar ea H2 ho TaCl5 ke (15-20):1, e leng eona e loketseng haholoanyane. Karolelano ea molar ea TaCl5 ho C3H6 e batla e le haufi le 3:1. TaCl5 e feteletseng kapa C3H6 e tla etsa hore ho thehoe Ta2C kapa carbon e sa lefelloeng, e amang boleng ba sephaphatha.

B. Thempereichara ea ho beoa: Ha mocheso o le holimo, lebelo la ho beoa le potlaka, boholo ba lijo-thollo bo ba kholoanyane, 'me lesela le thatafala le ho feta. Ho feta moo, mocheso le lebelo la ho bola ha hydrocarbon ho C le TaCl5 ho bola ho Ta li fapane, 'me Ta le C ho ka etsahala hore li thehe Ta2C. Thempereichara e na le tšusumetso e kholo ho TaC coating e fetotsoeng lisebelisoa tsa khabone. Ha mocheso oa deposition o ntse o eketseha, sekhahla sa deposition sea eketseha, boholo ba likaroloana boa eketseha, 'me sebopeho sa likaroloana se fetoha ho tloha ho spherical ho ea ho polyhedral. Ho feta moo, ha mocheso oa deposition o phahame, ho senyeha ha TaCl5 ka potlako, ho fokotseha ha C ho tla fokotseha, khatello e kholo ea ho roala, 'me mapetsong a tla hlahisoa habonolo. Leha ho le joalo, mocheso o tlase oa deposition o tla lebisa katlehong e tlase ea ho bea, nako e telele ea ho beha, le litšenyehelo tse phahameng tsa thepa e tala.

C. Khatello ea li-deposition: Khatello ea ho behoa e amana haufi-ufi le matla a mahala a holim'a lintho tse bonahalang 'me e tla ama nako ea ho lula ha khase ka kamoreng ea ho itšoara, kahoo e ama lebelo la nucleation le boholo ba karoloana ea ho roala. Ha khatello ea deposition e ntse e eketseha, nako ea ho lula ha khase e ba nako e telele, li-reactants li na le nako e eketsehileng ea ho etsa liphetoho tsa nucleation, lebelo la ho itšoara le eketseha, likaroloana li ba tse kholoanyane, 'me seaparo se fetoha se teteaneng; ka lehlakoreng le leng, ha khatello ea deposition e fokotseha, nako ea ho itšoara ka khase e khutšoanyane, sekhahla sa karabelo se fokotseha, likaroloana li fetoha tse nyenyane, 'me ho roala ho fokola, empa khatello ea deposition e na le phello e fokolang holim'a sebopeho sa kristale le sebopeho sa ho roala.

V. Mokhoa oa nts'etsopele oa ho roala ha tantalum carbide

Mocheso oa TaC (6.6×10−6K−1) o batla o fapane le oa thepa e entsoeng ka carbon e kang graphite, carbon fiber, le C/C composite thepa, e leng se etsang hore liphahlo tsa TaC tsa mokhahlelo o le mong li tsebe ho peperana le ho peperana. ho wela. Bakeng sa ho ntlafatsa ts'ebetso ea ho hema le ho hanyetsa oxidation, botsitso ba mochini o phahameng oa mocheso, le khanyetso e phahameng ea mocheso ea lik'hemik'hale ea likhahla tsa TaC, bafuputsi ba entse lipatlisiso mabapi le lits'ebetso tsa ho roala joalo ka litsamaiso tsa ho roala tse kopaneng, litsamaiso tse tiileng tse matlafatsang tharollo, le gradient. litsamaiso tsa ho roala.

Mokhoa oa ho roala o kopantsoeng ke ho koala mapetsong a lesela le le leng. Hangata, liphahlo tse ling li kenngoa ka holimo kapa ka hare ho lera la TaC ho etsa mokhoa oa ho roala o kopantsoeng; tharollo e tiileng e matlafatsang tsamaiso ea ho roala HfC, ZrC, joalo-joalo e na le sebopeho sa li-cubic tse nang le sefahleho se tšoanang le sa TaC, 'me li-carbide tse peli li ka qhibiliha ka ho sa feleng ho tse ling ho etsa moralo o tiileng oa tharollo. Thepa ea Hf(Ta)C ha e na mapetso 'me e khomarela hantle thepa e kopantsoeng ea C/C. Ho roala ho na le ts'ebetso e ntle ea anti-ablation; The gradient coating system coat gradient e bua ka karolo ea khoele e ipapisitseng le botenya ba eona. Sebopeho se ka fokotsa khatello ea kelello ka hare, ho ntlafatsa ho se lumellane ha li-coefficients tsa ho atolosa mocheso, le ho qoba mapetsong.

(II) Lihlahisoa tsa sesebelisoa sa Tantalum carbide

Ho ea ka lipalo-palo le bolepi ba esale pele ba QYR (Hengzhou Bozhi), thekiso ea 'maraka ea tantalum carbide coating ea lefats'e ka 2021 e fihlile ho US $ 1.5986 milione (ntle le lihlahisoa tsa mochini oa "tantalum carbide coating" tse iketselitseng tsona,' me e ntse e le mathoasong. mekhahlelo ea ntlafatso ea indasteri.

1. Mehele ea katoloso ea kristale le li-crucibles tse hlokahalang bakeng sa kholo ea kristale: Ho ipapisitsoe le libopi tsa kholo ea kristale tse 200 khoebong ka 'ngoe, karolo ea mmaraka ea lisebelisoa tse koahetsoeng ke TaC e hlokoang ke lik'hamphani tse 30 tsa kholo ea kristale e ka ba li-yuan tse limilione tse likete tse 4.7.

2. Literei tsa TaC: Terei e 'ngoe le e 'ngoe e ka nka liphaephe tse 3, terei ka 'ngoe e ka sebelisoa khoeli e le 'ngoe, 'me terei e le 'ngoe e jeoa bakeng sa li-wafer tse ling le tse ling tse 100. Li-wafer tse limilione tse 3 li hloka literei tsa TaC tse 30,000, terei ka 'ngoe e ka ba likotoana tse 20,000, 'me ho hlokahala tse ka bang limilione tse 600 selemo le selemo.

3. Maemo a mang a phokotso ea khabone. Joalo ka lesela la sebōpi se nang le mocheso o phahameng, CVD nozzle, liphaephe tsa sebōpi, joalo-joalo, tse ka bang limilione tse 100.

Nako ea poso: Jul-02-2024