Re ikemiselitse ho u fa theko e matla, lihlahisoa tse ikhethang le litharollo tsa boleng bo holimo, hammoho le phano e potlakileng ea Moetsi oa ODM Furnace Heater Sic Heating Elements; Muffle Frunace Sebelisa Sic Heater / Heating Element, Haeba u khahliloe ke efe kapa efe ea lihlahisoa tsa rona, ha ua lokela ho ikutloa u se na litšenyehelo tsa ho re letsetsa bakeng sa lintlha tse ling. Re tšepa ho sebelisana 'moho le metsoalle e mengata e haufi e tsoang lefats'eng lohle.

Re ikemiselitse ho u fa theko e mabifi, lihlahisoa tse ikhethang le litharollo tsa boleng bo holimo, hammoho le ho tsamaisa thepa ka potlako bakeng saChina Sic Heater le Silicon Carbide Heating Element, Hona joale re na le botumo bo botle ba lihlahisoa tsa boleng bo tsitsitseng, tse amoheloang hantle ke bareki lapeng le linaheng tse ling. Khampani ea rona e ne e tla tataisoa ke mohopolo oa "Ho ema Limmarakeng tsa Lehae, Ho Tsamaea ka Limmarakeng tsa Machaba". Re tšepa ka tieo hore re ka etsa khoebo le baetsi ba likoloi, bareki ba likarolo tsa likoloi le boholo ba basebetsi-'moho le rona lapeng le kantle ho naha. Re lebelletse tšebelisano 'moho le nts'etsopele e tšoanang!

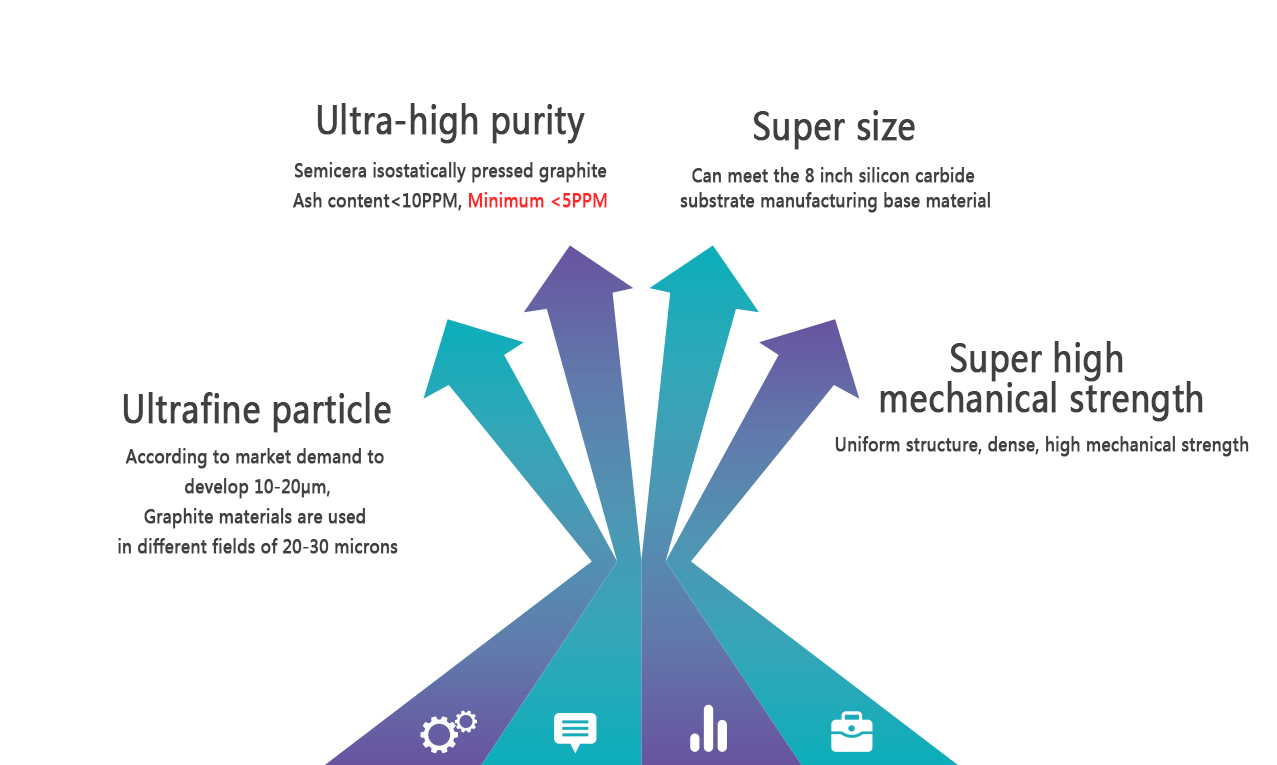

Lihlahisoa tse ka sehloohong tsa semicera ke graphite e hatelitsoeng ka isostatically e sebelisoang ho li-semiconductors. Lintlha tsa mantlha tsa lihlahisoa tse tsoetseng pele tsa Jeremane tsa SGL le Japanese Toyo carbon dihlahiswa tse latelang:

| Paramethara ea ts'ebetso | semicera | SGL R6510 | TOYO IG310 |

| Boima ba bongata (g/cm3) | 1.91 | 1.83 | 1.85 |

| Matla a ho kokota (MPa) | 63 | 60 | 49 |

| Matla a hatellang (MPa) | 135 | 130 | 103 |

| Bothata ba Lebōpo (HS) | 70 | 64 | 60 |

| Thermal conductivity (W/m·K) | 85 | 105 | 130 |

| Coefficient ea katoloso ea mocheso (10-6/K) | 5.85 | 4.2 | 5.0 |

| Ho hanyetsa (μΩm) | 11-13 | 13 | 10 |

Molemo oa ts'ebetso:

1.Sebopeho se setle ebile se teteaneng, 'me ho tšoana ho molemo.

2.Low coefficient ea ho atolosoa ha mocheso, ho hanyetsa mocheso o babatsehang oa mocheso;

3.Isotropy;

4.Ho hanyetsa lik'hemik'hale tse matla;

5.Good mogote le motlakase conductivity;

6.E na le thepa e babatsehang ea machining.

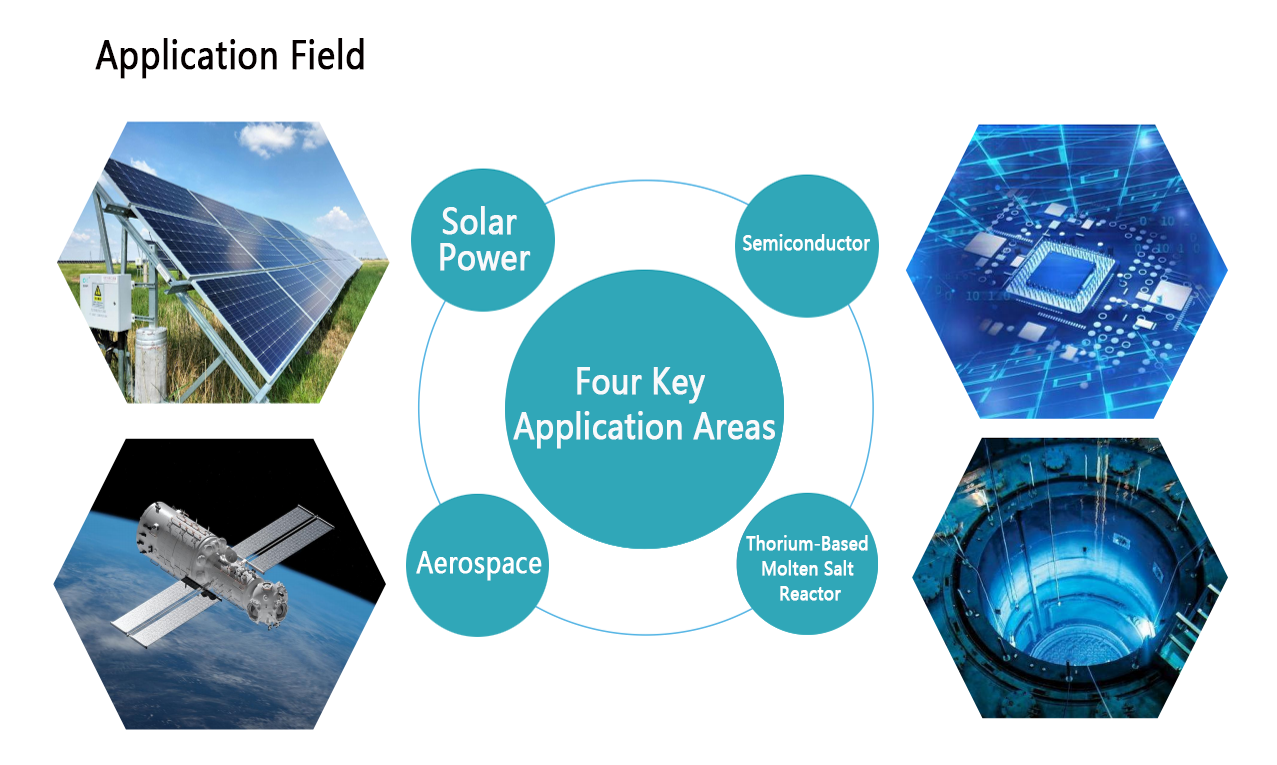

Lisebelisoa tsa mantlha tsa indasteri ea sejoale-joale

1. Indasteri ea semiconductor

2. Indasteri ea matla a letsatsi

3. Indasteri ea sepakapaka

4. Indasteri ea nyutlelie

Morero oa graphite oa Semicera isostatic, o bile ka tlhahiso ea bongata ho fumana letsoalo le phahameng, bohloeki bo phahameng, matla a phahameng, lihlahisoa tse kholo tsa graphite.

Re ikemiselitse ho u fa theko e matla, lihlahisoa tse ikhethang le litharollo tsa boleng bo holimo, hammoho le phano e potlakileng ea Moetsi oa ODM Furnace Heater Sic Heating Elements; Muffle Frunace Sebelisa Sic Heater / Heating Element, Haeba u khahliloe ke efe kapa efe ea lihlahisoa tsa rona, ha ua lokela ho ikutloa u se na litšenyehelo tsa ho re letsetsa bakeng sa lintlha tse ling. Re tšepa ho sebelisana 'moho le metsoalle e mengata e haufi e tsoang lefats'eng lohle.

Moetsi oa ODMChina Sic Heater le Silicon Carbide Heating Element, Hona joale re na le botumo bo botle ba lihlahisoa tsa boleng bo tsitsitseng, tse amoheloang hantle ke bareki lapeng le linaheng tse ling. Khampani ea rona e ne e tla tataisoa ke mohopolo oa "Ho ema Limmarakeng tsa Lehae, Ho Tsamaea ka Limmarakeng tsa Machaba". Re tšepa ka tieo hore re ka etsa khoebo le baetsi ba likoloi, bareki ba likarolo tsa likoloi le boholo ba basebetsi-'moho le rona lapeng le kantle ho naha. Re lebelletse tšebelisano 'moho le nts'etsopele e tšoanang!

-

Theko e utloahalang Soft Felt bakeng sa Heat Thermal Ins...

-

Semiconductor ea boleng bo botle ba Wafer Sucker Alumina ...

-

Theko e Khethehileng ea Carbon Soft bakeng sa Heat Insulati...

-

Mosebetsi o Phahameng oa Mocheso o Phahameng oa ho sebetsa o Refra...

-

Mofuta o motle oa H Mofuta oa Silicon Carbide Sic Rod Hea...

-

China wholesale Factory Price Custom Indasteri...