Silicon carbide ke mofuta o mocha oa li-ceramics tse nang le ts'ebetso ea theko e phahameng le thepa e ntle ea thepa. Ka lebaka la likarolo tse kang matla a phahameng le ho thatafala, ho hanyetsa mocheso o phahameng, mocheso o moholo oa mocheso le khanyetso ea ho bola ha lik'hemik'hale, Silicon Carbide e batla e khona ho mamella mefuta eohle ea lik'hemik'hale. Ka hona, SiC e sebelisoa haholo merafong ea oli, lik'hemik'hale, mechine le sefofane, esita le matla a nyutlelie le sesole li na le litlhoko tsa tsona tse khethehileng ho SIC. Lisebelisoa tse ling tse tloaelehileng tseo re ka fanang ka tsona ke mehele ea tiiso bakeng sa pompo, valve le lihlomo tse sireletsang joalo-joalo.

Re khona ho rala le ho etsa ho latela litekanyo tsa hau tse ikhethileng ka boleng bo botle le nako e loketseng ea ho fana.

Non-pressed sintered silicon carbide roller, sepakapaka sintered silicon carbide ceramic dihlahiswa tsa ceramic, tshebediso ya high pure pure ultrafine silicon carbide powder, sintered at 2450℃ high heat, silicon carbide content of more than 99.1%, product density ≥3.10g/ cm3, ha ho na litšila tsa tšepe tse kang silicon ea tšepe.

► Likahare tsa silicon carbide --≥99%;

► Ho hanyetsa mocheso o phahameng - tšebeliso e tloaelehileng ho 1800 ℃;

► Ts'ebetso e phahameng ea mocheso - e bapisoang le mocheso oa mocheso oa thepa ea graphite;

► boima bo phahameng - boima ba bobeli feela ho daemane, cubic boron nitride;

► Ho hanyetsa kutu - acid e matla le alkaline ha e na kutu, ho hanyetsa kutu ho molemo ho feta tungsten carbide le alumina;

► Boima bo bobebe - boima ba 3.10g / cm3, haufi le aluminium;

► Ha ho na deformation - coefficient e nyane haholo ea katoloso ea mocheso;

► Thermal shock resistance - thepa e ka mamella liphetoho tse potlakileng tsa mocheso, ho hanyetsa mocheso oa mocheso, ho hanyetsa serame le mocheso, ts'ebetso e tsitsitseng.

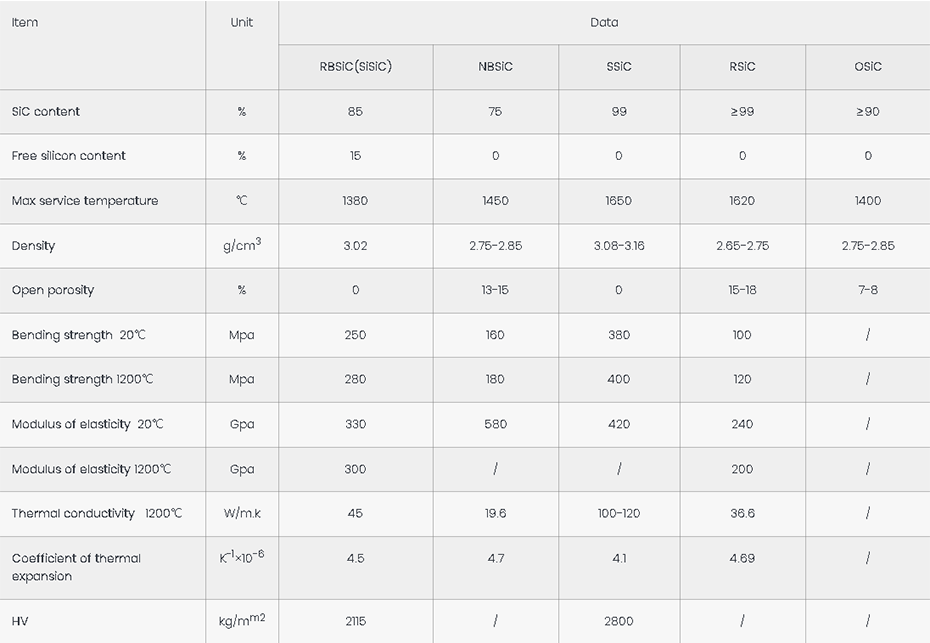

Litekanyetso tsa Tekheniki: