Semicera Special Graphite - E Etang Bokamoso ba Lisebelisoa tse Tsoetseng Pele

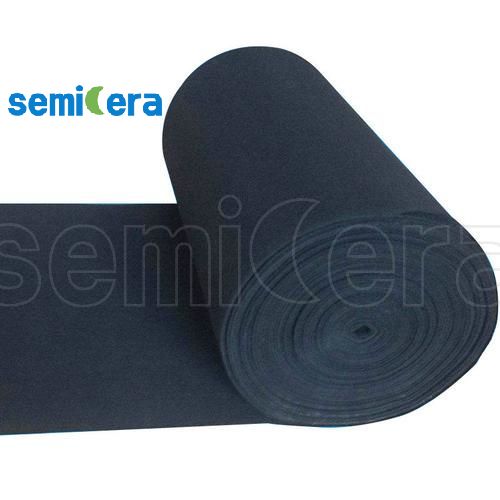

Semicera ke moetapele oa lefats'e oa tlhahiso ea graphite e khethehileng, e ikemiselitseng ho fana ka lihlahisoa tsa graphite tse sebetsang hantle, tse tšepahalang haholo ho pholletsa le liindasteri tse sa tšoaneng. Tsa ronagraphite ea isotropicthekenoloji, ka thepa ea eona e ikhethang le mefuta e mengata ea lits'ebetso, e fumane kananelo ho tsoa ho bareki lefatšeng ka bophara. Re fana ka litharollo tse etselitsoeng ho fihlela litlhoko tse tsoelang pele tsa 'maraka.

Likarolo tse Ikhethang tsa Graphite e Khethehileng

Ha tlhokahalo ea lisebelisoa tsa carbon tse tsitsitseng le tse hloekisitsoeng li ntse li eketseha, Semicera e 'nile ea e-ba ka pele ho mekhoa e mecha, ho hlahisa graphite ea boleng bo phahameng ba isotropic. Ho sebelisaCold Isostatic Pressing (CIP)thekenoloji, re hatella likaroloana tsa boholo ba micron hore e be mehaho ea graphite e nepahetseng haholo, e leng se hlahisang lisebelisoa tse khethehileng tsa graphite tse nang le ts'ebetso e phahameng. Lihlahisoa tsa rona tse khethehileng tsa graphite li sebelisoa haholo ho pholletsa le liindasteri, ho kenyelletsa le li-semiconductors, matla a se nang botsoalle ho tikoloho, le ho bopa ka mokhoa o nepahetseng, ho bontša melemo ea bona e ke keng ea lekanngoa.

Likarolo tsa Bohlokoa:

▪Thepa e ikhethang ea Isotropic

Isotropic graphite e bonts'a thepa e tšoanang ea 'mele le ea lik'hemik'hale ka nqa tsohle, e etsa hore ho be bonolo ho e qapa le ho e sebelisa. Thepa ena e eketsa ts'ebeliso ea eona libakeng tse nepahetseng haholo.

▪Ho Tšepahala ho Phahameng

Sebopeho sa micro-particle sa isotropic graphite se etsa hore se be matla ho feta graphite e tloaelehileng, e nang le phapang e fokolang ea thepa, ho netefatsa botsitso le ho tšepahala libakeng tse hlokang.

▪Ultra-High Heat Resistance

Libakeng tse sa sebetseng hantle, graphite ea isotropic e ka sebelisoa ka mokhoa o tsitsitseng mochesong o phahameng haholo o ka holimo ho 2000 ℃. E na le coefficient e tlase ea ho atolosa mocheso le conductivity e phahameng ea mocheso, e fana ka ts'ebetso e babatsehang ea ho hanyetsa mocheso le thepa ea ho arola mocheso.

▪Khokahano e Ntle ea Motlakase

Ka lebaka la ho hanyetsa mocheso o phahameng, graphite ke thepa e loketseng bakeng sa lisebelisoa tse kang li-heaters tse nang le mocheso o phahameng le lisebelisoa tse ling tse matla tsa motlakase.

▪Botsitso ba Lik'hemik'hale

Isotropic graphite e tsitsitse ka lik'hemik'hale, ha e khone ho bola libakeng tse ngata, ntle le lintho tse ling tse matla tsa oxidizing.

▪E bobebe ebile e bonolo ho Mochini

Ka boima bo tlase ba bongata ha bo bapisoa le lisebelisoa tsa tšepe, graphite e lumella moralo o bobebe. E boetse e na le machinability e babatsehang, e nolofatsang mekhoa e nepahetseng ea ho bōpa.

Lisebelisoa tsa Graphite e khethehileng

Lihlahisoa tse khethehileng tsa graphite tsa Semicera li sebelisoa haholo liindastering tse fapaneng tse bohlokoa bophelong ba sejoale-joale.

1. Indasteri ea Tikoloho le Matla:

▪Tlhahiso ea Solar Cell le Wafer: Ka indasteri ea photovoltaic, Semicera e fana ka lisebelisoa tse phahameng tsa graphite tse sebelisoang ha ho etsoa tlhahiso ea lisele tsa letsatsi le li-wafers.

▪Fluorine ElectrolysisleLisele tsa Mafura: Lisebelisoa tsa rona tsa graphite li sebelisoa ho electrolysis e phahameng ea mocheso le lisebelisoa tsa lisele tsa mafura, tse fanang ka ho hanyetsa mocheso o babatsehang le ho hanyetsa kutu.

▪Polycrystalline le Single Crystal Silicon Manufacturing: Lefapheng la semiconductor, lihlahisoa tsa graphite tsa Semicera li sebelisoa ho hlahisa polycrystalline e phahameng ea bohloeki le silicon e le 'ngoe ea kristale, ho netefatsa ho nepahala le boleng bo phahameng.

▪White LED Manufacturing: Graphite e ntle haholo ea mocheso oa mocheso o etsa hore e be thepa e loketseng bakeng sa ho paka ka LED le ho senya mocheso.

▪Precision Mold Processing: Lisebelisoa tsa graphite tsa Semicera li sebelisoa haholo ka mokhoa o nepahetseng oa ho etsa hlobo, haholo-holo ho Motlakase oa Ts'ebetso ea Motlakase (EDM), moo ho nepahala ho phahameng ho leng bohlokoa.

▪Libōpi tsa indasteri: E sebelisoa libakeng tse nang le mocheso o phahameng joalo ka libopi tsa metallurgy le ts'ebetso ea thepa.

▪Ho Lahla ho Tsoelang Pele Hoa Shoa: Lisebelisoa tsa rona tsa graphite li sebelisoa ho lahla ho sa khaotseng bakeng sa li-alloys tsa koporo, lisebelisoa tsa aluminium le lisebelisoa tse ling.

2. Indasteri ea semiconductor:

▪Polycrystalline le Single Crystal Silicon Manufacturing: Lefapheng la semiconductor, lihlahisoa tsa graphite tsa Semicera li sebelisoa ho hlahisa polycrystalline e phahameng ea bohloeki le silicon e le 'ngoe ea kristale, ho netefatsa ho nepahala le boleng bo phahameng.

▪White LED Manufacturing: Graphite e ntle haholo ea mocheso oa mocheso o etsa hore e be thepa e loketseng bakeng sa ho paka ka LED le ho senya mocheso.

3. Indasteri ea Molding:

▪Precision Mold Processing: Lisebelisoa tsa graphite tsa Semicera li sebelisoa haholo ka mokhoa o nepahetseng oa ho etsa hlobo, haholo-holo ho Motlakase oa Ts'ebetso ea Motlakase (EDM), moo ho nepahala ho phahameng ho leng bohlokoa.

4. Lisebelisoa tse ling:

▪Libōpi tsa indasteri: E sebelisoa libakeng tse nang le mocheso o phahameng joalo ka libopi tsa metallurgy le ts'ebetso ea thepa.

▪Ho Lahla ho Tsoelang Pele Hoa Shoa: Lisebelisoa tsa rona tsa graphite li sebelisoa ho lahla ho sa khaotseng bakeng sa li-alloys tsa koporo, lisebelisoa tsa aluminium le lisebelisoa tse ling.

Ke Hobane'ng ha U Khetha Semicera?

Joaloka moetapele oa indasteri tlhahisong e khethehileng ea graphite, Semicera o na le lilemo tsa boiphihlelo ba tekheniki le boiphihlelo ba indasteri. Re sebelisa mekhoa e tsoetseng pele ea tlhahiso ho fana ka litharollo tsa boleng bo holimo, tse etselitsoeng bareki ba rona. Ebang ke bakeng sa tlhahiso ea boleng bo holimo ea semiconductor kapa lisebelisoa tsa indasteri tse nang le mocheso o phahameng, lihlahisoa tse khethehileng tsa graphite tsa Semicera li fana ka tšehetso e tšepahalang litlhoko tsa khoebo ea hau.