Zirconia ke thepa e nang le matla a phahameng a mochine le ho robeha ho thata ka mocheso oa kamore. Zirconia ea rona (ZrO2) e kenyelelitsoe ka 3mol% Y2O3 zirconia e tsitsitseng e tsitsitseng (PSZ). Hobane bophara ba karoloana ea thepa ea PSZ e nyane, e ka sebetsoa ka nepo e phahameng, mme ts'ebeliso ea eona likarolong tse nepahetseng tsa machining joalo ka hlobo e ntse e hola. Ntle le moo, e ka sebelisoa bakeng sa lisebelisoa tsa indasteri, likarolo tsa sehokelo sa optical le lisebelisoa tse silakanyang. The high fracture toughness of PSZ e ka sebelisoa ho etsa liliba tse khethehileng, hape e sebelisoa haholo ka lithipa tsa ceramic tsa malapeng, slicer le likarolo tse ling.

Litšobotsi tse ka sehloohong tsa likarolo tsa zirconia tsa ceramic:

1. Ho hanyetsa ho apara ka mokhoa o babatsehang, makhetlo a 276 a phahameng haholo ho feta tšepe e sa hloekang

2. Boima bo phahameng ho feta lirafshoa tse ngata tsa tekheniki, tse fetang 6 g/cm3

3. Boima bo phahameng, ho feta 1300 MPa bakeng sa Vicker

4. E khona ho mamella mocheso o phahameng ho fihlela ho 2400 °

5. Thermal conductivity e tlaase, e ka tlaase ho 3 W / mk mocheso oa kamore

6. Coefficient e tšoanang ea katoloso ea mocheso e le tšepe e sa hloekang

7. Ho robeha ka mokhoa o ikhethang ho fihla ho 8 Mpa m1/2

8. Ho se sebetse ha lik'hemik'hale, ho hanyetsa botsofali, le ho se ruse ka ho sa feleng

9. Ho hanana le litšepe tse qhibilihisitsoeng ka lebaka la ho qhibiliha ho sa tloaelehang.

Thepa Thepa

| Ntho | 95% Alumina | 99% Alumina | Zirconia | Silicon carbide | SiliconeNitride | AluminiumNitride | Ceramic e sebetsang |

| Mmala | tšoeu | Bosehla bo kganyang | tšoeu | ntsho | ntsho | bohlooho | tšoeu |

| Boima ba 'mele (g/cm3) | 3.7g/cm3 | 3.9g/cm3 | 6.02g/cm3 | 3.2g/cm3 | 3.25g/cm3 | 3.2g/cm3 | 2.48g/cm3 |

| Ho Monyeha ha Metsi | 0% | 0% | 0% | 0% | 0% | 0% | 0% |

| Ho thatafala(HV) | 23.7 | 23.7 | 16.5 | 33 | 20 | - | - |

| Flexural Strength(MPa) | 300MPa | 400MPa | 1100MPa | 450MPa | 800MPa | 310MPa | 91MPa |

| Compressive Strength(MPa) | 2500MPa | 2800MPa | 3600MPa | 2000MPa | 2600MPa | - | 340MPa |

| Modulus ea Mocha oa Elasticity | 300GPa | 300GPa | 320GPa | 450GPa | 290GPa | 310 ~ 350GPa | 65GPa |

| Karolelano ea Poisson | 0.23 | 0.23 | 0.25 | 0.14 | 0.24 | 0.24 | 0.29 |

| Thermal Conductivity | 20W/m°C | 32W/m°C | 3W/m°C | 50W/m°C | 25W/m°C | 150W/m°C | 1.46W/m°C |

| Matla a Dielectric | 14KV/mm | 14KV/mm | 14KV/mm | 14KV/mm | 14KV/mm | 14KV/mm | 14KV/mm |

| Ho hanyetsa Bophahamo (25℃) | >1014Ω·cm | >1014Ω·cm | >1014Ω·cm | >105Ω·cm | >1014Ω·cm | >1014Ω·cm | >1014Ω·cm |

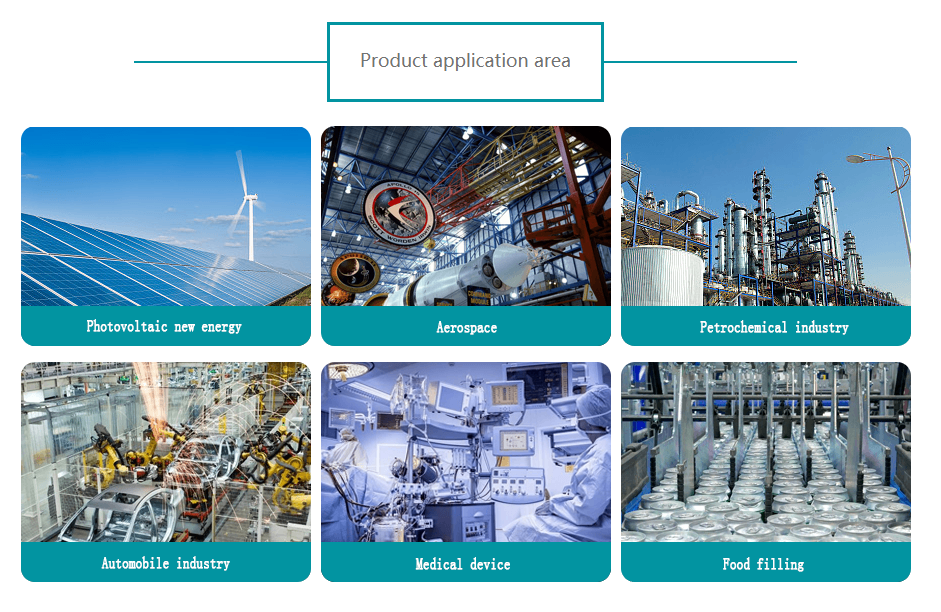

Zirconia (ZrO2) Ke sebelisa haholo

Lisebelisoa tsa hlobo le hlobo (liforomo tse fapa-fapaneng, mokhoa o nepahetseng oa ho beha maemo, ho kenya letsoho); Likarolo tsa Mill (classifier, leloala la phallo ea moea, leloala la lifaha); Sesebelisoa sa indasteri (seha sa indasteri, mochini oa slitter, moqolo oa khatiso o bataletseng); Likarolo tsa sehokelo sa Optical (ring ea ho tiisa, sleeve, sebopeho sa V-groove); Selemo se khethehileng (coil spring, plate spring); Lihlahisoa tsa bareki (screwdriver tse nyane tse insulated, thipa ea ceramic, slicer).