Tlhaloso

Re boloka mamello e haufi haholo ha re etsa kopo eaHo roala ha SiC, ho sebelisa machining a phahameng ka ho fetisisa ho etsa bonnete ba hore ho na le boemo bo tšoanang ba susceptor. Re boetse re hlahisa lisebelisoa tse nang le thepa e nepahetseng ea ho hanyetsa motlakase bakeng sa ho sebelisoa lits'ebetsong tse futhumatsang ka matla. Likarolo tsohle tse phethiloeng li tla le setifikeiti sa ho hloeka le ho lumellana ha dimensional.

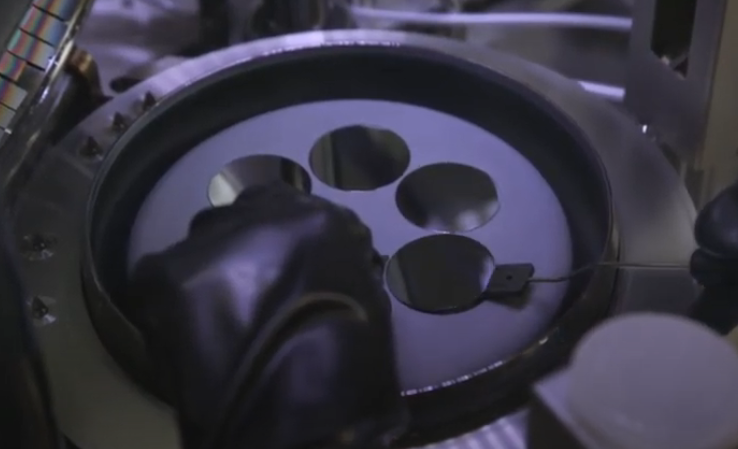

Khampani ea rona e fana kaHo roala ha SiClits'ebeletso tsa ts'ebetso ka mokhoa oa CVD holim'a graphite, li-ceramics le lisebelisoa tse ling, e le hore likhase tse khethehileng tse nang le k'habone le silicon li itšoare ka mocheso o phahameng ho fumana limolek'hule tse phahameng tsa SiC, limolek'hule tse behiloeng holim'a lisebelisoa tse koahetsoeng, ho etsa lera le sireletsang SIC. SIC e entsoeng e tlamahane ka thata ho setsi sa graphite, e fana ka lisebelisoa tse khethehileng tsa graphite, kahoo e etsa hore bokaholimo ba graphite bo kopane, bo se ke ba e-ba le Porosity, ho hanyetsa mocheso o phahameng, ho hanyetsa kutu le ho hanyetsa oxidation.

Ts'ebetso ea CVD e fana ka bohloeki bo phahameng haholo le boits'oaro ba khopolo-taba eaHo roala ha SiCe se nang porosity. Ho feta moo, kaha silicon carbide e thata haholo, e ka belisoa hore e be holim'a seipone.CVD silicon carbide (SiC) ho roalae ile ea fana ka melemo e mengata ho kenyelletsa le holimo-holimo ho hloeka le ho tšoarella ka ho fetelletseng. Kaha lihlahisoa tse koahetsoeng li na le ts'ebetso e ntle maemong a phahameng a vacuum le mocheso o phahameng, li loketse lits'ebetso indastering ea semiconductor le tikolohong e 'ngoe e hloekileng haholo. Re boetse re fana ka lihlahisoa tsa pyrolytic graphite (PG).

Likarolo tse ka Sehloohong

1. Ho hanyetsa mocheso o phahameng oa oxidation:

khanyetso ea oxidation e ntse e le ntle haholo ha mocheso o le holimo ho 1600 C.

2. Bohloeki bo phahameng: bo entsoeng ka ho kenngoa ha mouoane oa lik'hemik'hale tlas'a boemo bo phahameng ba mocheso oa chlorination.

3. Ho hanyetsa khoholeho ea mobu: boima bo phahameng, bokaholimo bo kopanetsoeng, likaroloana tse ntle.

4. Ho hanyetsa kutu: acid, alkali, letsoai le li-reagents tse phelang.

Lintlha tse ka sehloohong tsa CVD-SIC Coatings

| SiC-CVD | ||

| Botenya | (g/cc) | 3.21 |

| Matla a flexural | (Mpa) | 470 |

| Katoloso ea mocheso | (10-6/K) | 4 |

| Thermal conductivity | (W/mK) | 300 |

Kopo

CVD silicon carbide coating e se e sebelisitsoe indastering ea semiconductor e se e ntse e sebelisoa, joalo ka tray ea MOCVD, RTP le oxide etching chamber kaha silicon nitride e na le matla a maholo a ho hanyetsa mocheso 'me e khona ho mamella plasma e matla ea matla.

-Silicon carbide e sebelisoa haholo ho semiconductor le ho roala.

Kopo

Matla a Phepelo:

10000 Pejana / Likotoana ka Khoeli

Ho paka & Delivery:

Ho paka: Ho paka ka mokhoa o tloaelehileng le o matla

Poly bag + Lebokose + Carton + Pallet

Boema-kepe:

Ningbo/Shenzhen/Shanghai

Lead time:

| Bongata(Likotoana) | 1 - 1000 | >1000 |

| EST. Nako(matsatsi) | 30 | Ho buisanoa |