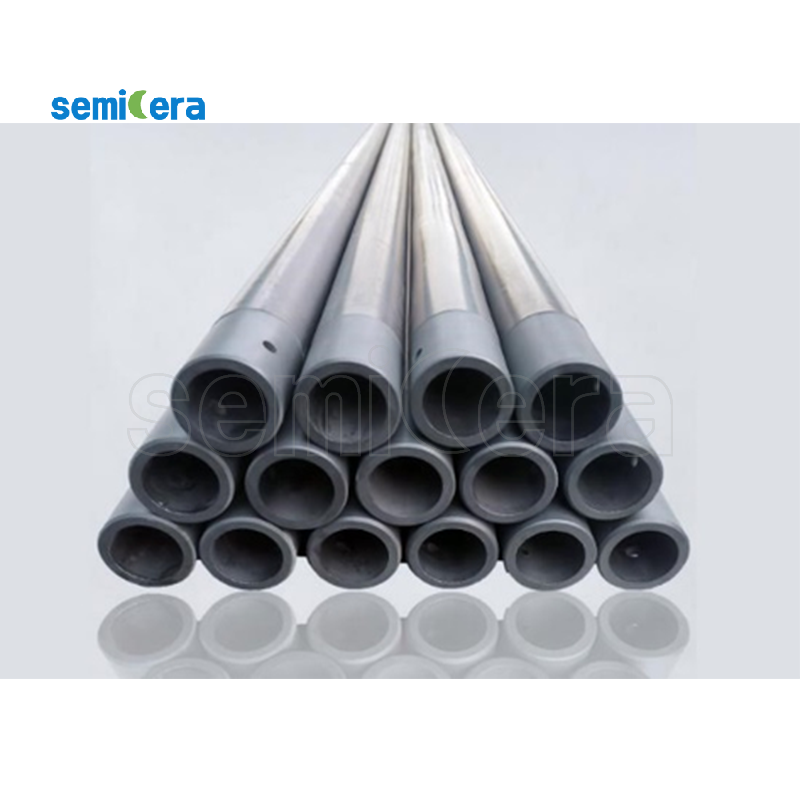

Silicon carbide ceramic mandrel ke ntho e bōpehileng joaloka molamu e entsoeng ka silicon carbide ceramic material. Silicon carbide ceramic mandrel e na le thepa e ntle ea 'mele le ea lik'hemik'hale' me e sebelisoa haholo masimong a indasteri tlas'a mocheso o phahameng, khatello e phahameng le tikoloho e senyang.

Silicon carbide ke mofuta o mocha oa li-ceramics tse nang le ts'ebetso ea theko e phahameng le thepa e ntle ea thepa. Ka lebaka la likarolo tse kang matla a phahameng le ho thatafala, ho hanyetsa mocheso o phahameng, mocheso o moholo oa mocheso le khanyetso ea ho bola ha lik'hemik'hale, Silicon Carbide e batla e khona ho mamella mefuta eohle ea lik'hemik'hale. Ka hona, SiC e sebelisoa haholo merafong ea oli, lik'hemik'hale, mechine le sefofane, esita le matla a nyutlelie le sesole li na le litlhoko tsa tsona tse khethehileng ho SIC. Lisebelisoa tse ling tse tloaelehileng tseo re ka fanang ka tsona ke mehele ea tiiso bakeng sa pompo, valve le lihlomo tse sireletsang joalo-joalo.

Sebopeho le boholo li ka etsoa ho latela litlhoko

Ho thatafala haholo (HV10): 22.2(Gpa)

Boima bo tlase haholo (3.10-3.20 g/cm³)

Ha mocheso o fihla ho 1400 ℃, SiC e ka boloka matla a eona

Ka lebaka la botsitso ba eona ba lik'hemik'hale le 'mele, SiC e na le boima bo phahameng le ho hanyetsa kutu.

Lintlha tse ka sehloohong:

1. Botsitso bo phahameng ba mocheso: Silicon carbide ceramic mandrel e ka boloka botsitso ba sebopeho sa eona le ts'ebetso sebakeng se phahameng sa mocheso. E khona ho mamella mocheso o phahameng haholo 'me e na le mocheso o motle haholo oa ho hanyetsa, o loketseng likopo tsa mekhoa ea mocheso o phahameng le lisebelisoa.

2. Corrosion resistance: Silicon carbide ceramic mandrel e na le khanyetso e ntle ea kutu 'me e khona ho hanela khoholeho ea li-acids, alkalis, solvents le mecha ea litaba e senyang. E ke ke ea itšoara ka lik'hemik'hale kapa ea senyeha sebakeng se senyang, ho boloka ts'ebetso ea eona ea pele le botsitso.

3. Ho hanyetsa ho roala: Silicon carbide ceramic mandrel e na le boima bo phahameng ka ho fetisisa le ho hanyetsa ho roala, 'me e ka boloka tekanyo e tlaase ea ho apara tlas'a lebelo le phahameng le maemo a phahameng a likhohlano. Sena se etsa hore e be le bophelo bo bolelele le ho ts'epahala sebakeng se thata sa ho apara.

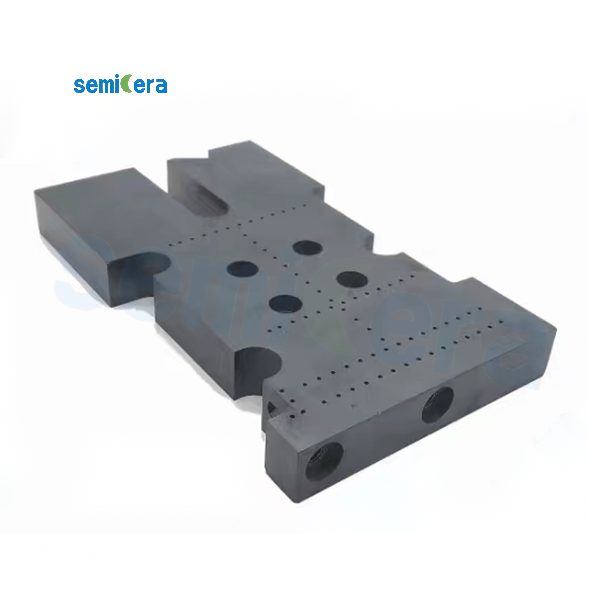

4. Ts'ebetso e ntle ea ho pata: Silicon carbide ceramic mandrel e na le ts'ebetso e ntle ea ho pata 'me e ka fana ka tšireletso e ka tšeptjoang ka tlas'a maemo a phahameng a motlakase le maemo a phahameng a motlakase. E sebelisoa haholo ho lisebelisoa tse phahameng tsa motlakase le likarolo tsa ho kenya letsoho masimong a matla, lisebelisoa tsa elektroniki le li-semiconductors.

5. Boima bo bobebe le matla a phahameng: Silicon carbide ceramic mandrels e na le sekhahla se tlaase le matla a phahameng, 'me e na le thepa e babatsehang ea mochine. Li na le matla a holimo a ho kobeha le a thata 'me li khona ho mamella khatello e phahameng le khatello ea mochine.

-

Khatiso e sa lefelloeng ea sintered silicon carbide saggar

-

High Wear Resistance Silicon Carbide Ceramic Li...

-

Silicon Carbide Ceramic Seal Ring

-

Li-roller tsa ceramic tsa SiC

-

Likarolo tsa sebopeho sa Silicon carbide li ka etsoa ka mokhoa o ikhethileng

-

Mocheso o phahameng o hanyetsanang le silicon carbide cera...