Tlhaloso

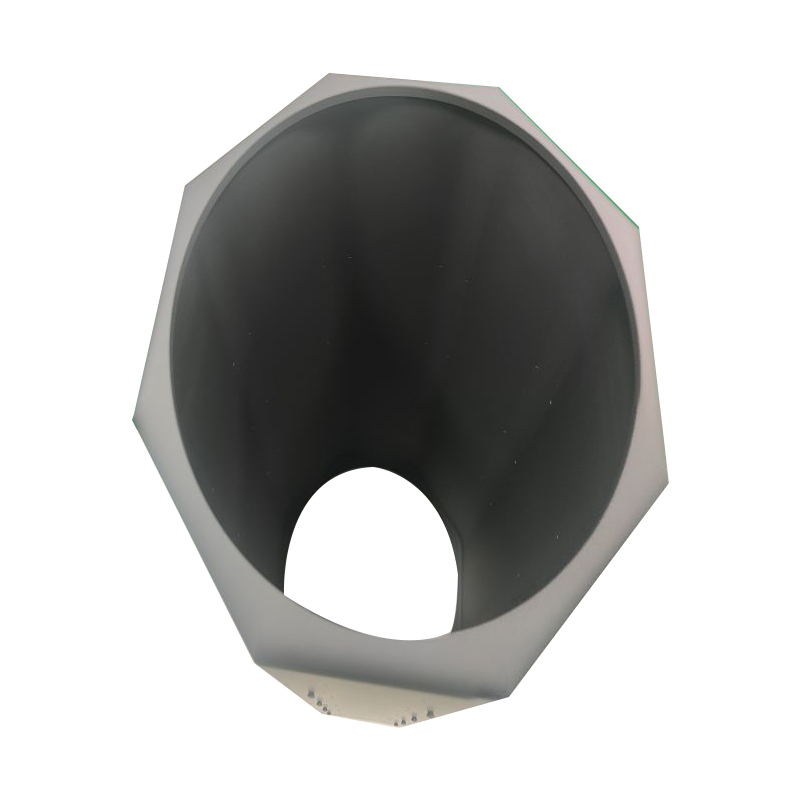

Khampani ea rona e fana kaHo roala ha SiCts'ebetso ea litšebeletso holim'a graphite, ceramics le lisebelisoa tse ling ka mokhoa oa CVD, e le hore likhase tse khethehileng tse nang le carbon le silicon li ka itšoara ka mocheso o phahameng ho fumana limolek'hule tsa Sic tse hloekileng, tse ka behoang holim'a lisebelisoa tse koahetsoeng ho etsaLera le sireletsang la SiCbakeng sa mofuta oa epitaxy barrel hy pnotic.

Likarolo tse ka Sehloohong

1. Ho hanyetsa mocheso o phahameng oa oxidation:

khanyetso ea oxidation e ntse e le ntle haholo ha mocheso o le holimo ho 1600 C.

2. Bohloeki bo phahameng : bo entsoeng ka ho kenngoa ha mouoane oa lik'hemik'hale tlas'a boemo bo phahameng ba mocheso oa chlorination.

3. Ho hanyetsa khoholeho ea mobu: boima bo phahameng, bokaholimo bo kopanetsoeng, likaroloana tse ntle.

4. Ho hanyetsa kutu: acid, alkali, letsoai le li-reagents tse phelang.

Lintlha tse ka sehloohong tsa CVD-SIC Coating

| SiC-CVD Properties | ||

| Sebopeho sa Crystal | FCC mohato oa β | |

| Botenya | g/cm³ | 3.21 |

| Ho thatafala | Vickers thata | 2500 |

| Boholo ba lijo-thollo | μm | 2~10 |

| Bohloeki ba Lik'hemik'hale | % | 99.99995 |

| Matla a Mocheso | J·kg-1 ·K-1 | 640 |

| Sublimation Mocheso | ℃ | 2700 |

| Felexural Matla | MPa (RT 4-point) | 415 |

| Modulus e monyane | Gpa (4pt bend, 1300 ℃) | 430 |

| Katoloso ea Thermal (CTE) | 10-6K-1 | 4.5 |

| Thermal conductivity | (W/mK) | 300 |