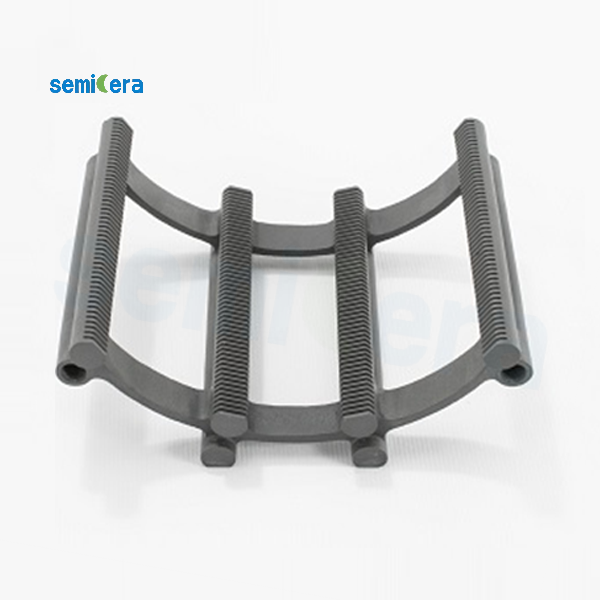

Ho sila disc ke sesebelisoa sa bohlokoa sa ts'ebetso bakeng sa tlhahiso ea li-wafers tsa silicon bakeng sa lipotoloho tse kopaneng tse kholo indastering ea semiconductor. Hangata e sebelisoa ka tšepe e entsoeng ka tšepe kapa carbon steel grinding disc e na le bophelo bo tlaase ba tšebeletso le coefficient e kholo ea katoloso ea mocheso. Ha ho etsoa li-wafers tsa silicon, haholo-holo ts'ebetsong ea ho sila kapa ho belisoa ka lebelo le phahameng, ho thata ho netefatsa ho bata le ho ts'oana ha li-wafers tsa silicon ka lebaka la ho senyeha le mocheso oa mocheso oa disc ea ho sila.

Sila disk ea silicon carbide ceramic e ka siloa le ho belisoa ka lebelo le phahameng ka lebaka la ho thatafala ho hoholo le ho senyeha ho honyenyane ha diski ea ho sila, 'me motsoako oa ho atolosa mocheso o tšoana hantle le oa sephaphatha sa silicon. Haholo-holo lilemong tsa morao tjena, boholo ba silicon wafer e ntse e hola le ho hola, e leng se fanang ka litlhoko tse phahameng tsa boleng le bokhoni ba ho sila ka silicon.

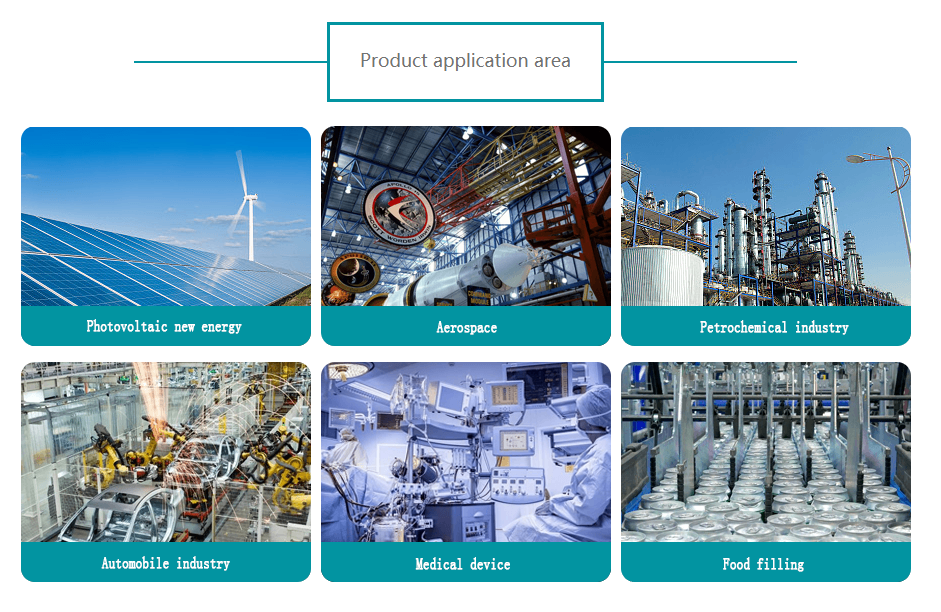

Tšebeliso ea silicon carbide ceramic grinding disc e tla ntlafatsa haholo boleng le bokhoni ba ho sila ka silicon. Ka nako e ts'oanang, silicon carbide ceramic grinding disk e ka boela ea sebelisoa ho sila le ho bentša sefofane sa lisebelisoa tse ling tse kang flake kapa block objects. Ka nts'etsopele ea nts'etsopele ea indasteri, haholo-holo ho kengoa ts'ebetsong ha maemo a machaba a ISO14000, litlhoko tse phahameng li behiloe pele bakeng sa ho tsamaisa lino tse sa lokeleng ts'ireletso ea tikoloho.

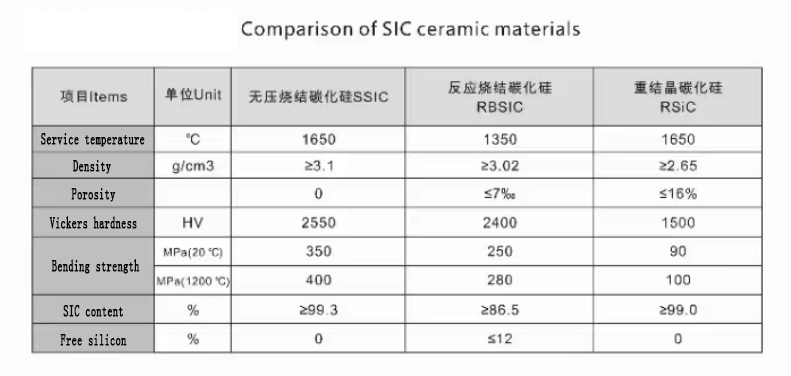

E 'ngoe ea litšobotsi tsa bohlokoa ka ho fetisisa tsa silicon carbide ceramics ke matla a eona a mocheso o phahameng, ke hore, matla ha a fokotsehe ka likhato tse 1600, 'me ho hanyetsa ha oxidation ho molemo haholo, kahoo e ka sebelisoa likarolong tse phahameng tsa mocheso. Joalo ka poleiti e holimo ea sebōpi sa mocheso o phahameng, tšehetso, le lisebelisoa tsa liteko tsa mocheso o phahameng.

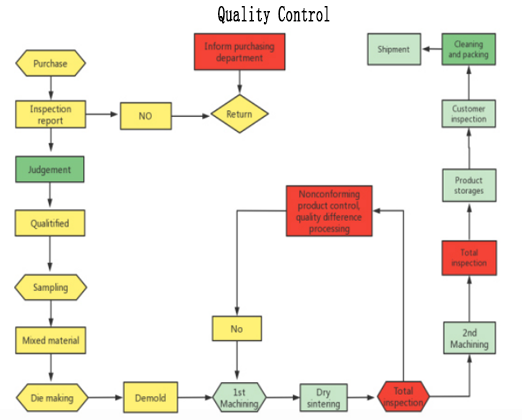

SemiceraEnergy Technology Co., Ltd ke setsebi sa lipatlisiso, nts'etsopele, tlhahiso le thekiso ea lihlahisoa tsa silicon carbide ceramic.Ho tloha ha e thehoa ka 2016,SemiceraMatla a tseba mokhoa oa ho bopa oa isostatic, ts'ebetso ea ho bopa e sekete, mokhoa oa ho bopa oa grouting le ts'ebetso ea ho bopa ka vacuum extrusion. Khamphani ea rona e sebelisa melapo e 6 ea tlhahiso ea silicon carbide ceramic sintering, e na le 8 CNC, 6 mechini e nepahetseng ea ho sila, e ka boela ea u fa lihlahisoa tsa silicon carbide ceramic sintered, empa hape e ka fana ka silicon carbide ceramics, alumina ceramics, aluminium nitride ceramics, zirconia ceramics processing services. .

-

Likhamphani tsa Tlhahiso bakeng sa Graphite Soft Felt ...

-

Theko e kholo ea Polyacrylonitrile Thermal Insul...

-

2019 Silicon Carbide Liner Sisic ea boleng bo holimo ea T...

-

Tloaelehileng Thekotso Motlakase Habeli Spiral Cerami...

-

Setsebi sa China Silicon Carbide Graphite Cru...

-

Sampole ea Mahala bakeng sa Lihlahisoa tsa Mofuta o Khethehileng oa Sic habeli...