Mehele e tiileng ea CVD SiCli sebelisoa haholo libakeng tsa indasteri le tsa mahlale maemong a mocheso o phahameng, libaka tse senyang le tse senyang. E bapala karolo ea bohlokoa libakeng tse ngata tsa ts'ebeliso, ho kenyelletsa:

1. Ho etsa semiconductor:Mehele e tiileng ea CVD SiCe ka sebelisoa bakeng sa ho futhumatsa le ho pholisa lisebelisoa tsa semiconductor, ho fana ka taolo e tsitsitseng ea mocheso ho netefatsa ho nepahala le ho tsitsa ha ts'ebetso.

2. Optoelectronics: Ka lebaka la conductivity ea eona e ntle ea mocheso le ho hanyetsa mocheso o phahameng,Mehele e tiileng ea CVD SiCe ka sebelisoa e le lisebelisoa tsa ts'ehetso le ho chesa mocheso bakeng sa lasers, lisebelisoa tsa puisano tsa fiber optic le likarolo tsa optical.

3. Mechine e nepahetseng: Mehele e tiileng ea CVD SiC e ka sebelisoa bakeng sa lisebelisoa le lisebelisoa tse nepahetseng mocheso o phahameng le libaka tse senyang, tse kang libōpi tsa mocheso o phahameng, lisebelisoa tsa vacuum le lik'hemik'hale tsa lik'hemik'hale.

4. Indasteri ea lik'hemik'hale: Mehele e tiileng ea CVD SiC e ka sebelisoa ka har'a lijana, liphaephe le li-reactors ka lik'hemik'hale tsa lik'hemik'hale le mekhoa ea catalytic ka lebaka la ho hanyetsa ha bona le botsitso ba lik'hemik'hale.

✓Boleng ba boleng bo holimo 'marakeng oa China

✓Tšebeletso e ntle ho uena kamehla, lihora tse 7*24

✓Letsatsi le lekgutshwane la ho beleha

✓MOQ e nyane e amohelehile ebile e amohetsoe

✓Litšebeletso tse ikhethileng

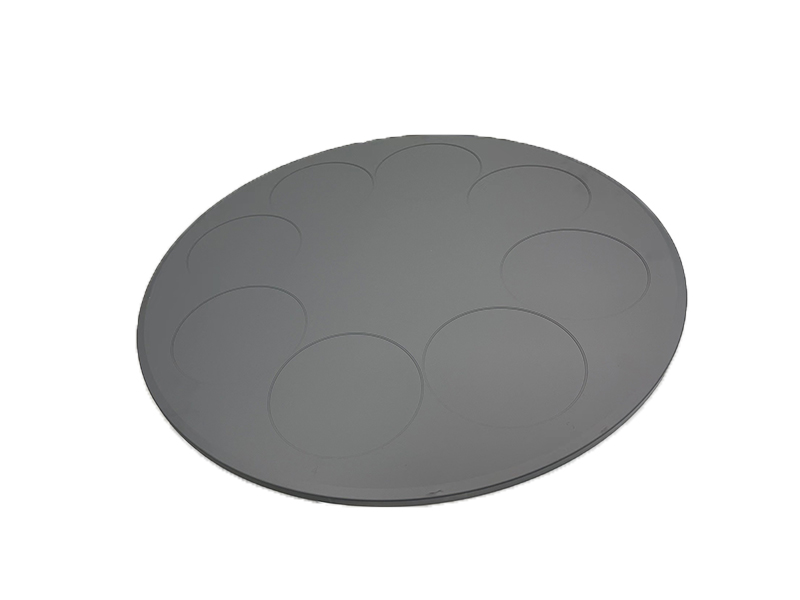

Epitaxy Growth Susceptor

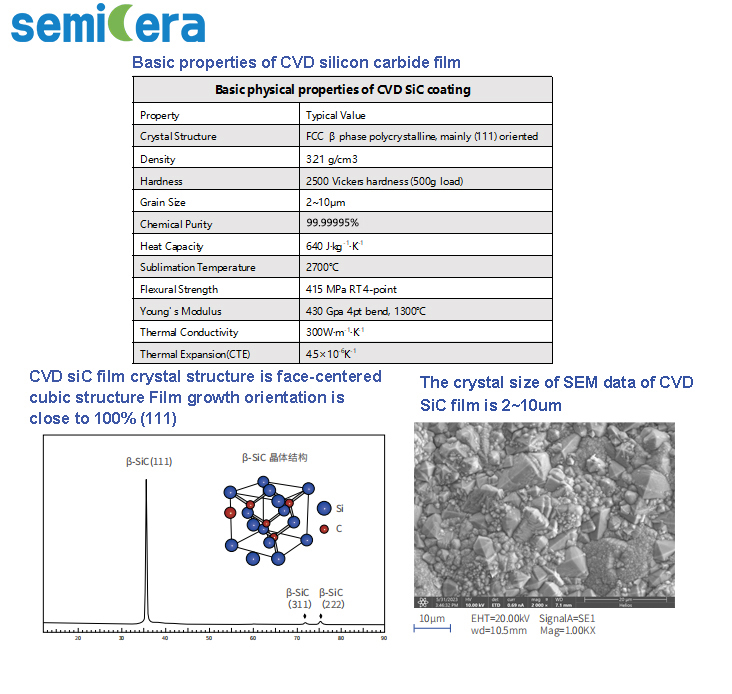

Li-wafers tsa silicon / silicon carbide li hloka ho feta lits'ebetsong tse ngata tse lokelang ho sebelisoa lisebelisoa tsa elektroniki. Ts'ebetso ea bohlokoa ke silicon / sic epitaxy, eo ho eona liphaephe tsa silicon / sic li tsamaisoang holim'a setsi sa graphite. Melemo e ikhethang ea Semicera's silicon carbide-coated graphite base e kenyelletsa bohloeki bo phahameng haholo, ho roala ka mokhoa o ts'oanang, le bophelo bo bolelele ba ts'ebeletso. Li boetse li na le khanyetso e phahameng ea lik'hemik'hale le botsitso ba mocheso.

Tlhahiso ea Chip ea LED

Nakong ea ho roala ho pharaletseng ha mochine oa MOCVD, setsi sa polanete kapa sejari se tsamaisa sephaphatha sa substrate. Ts'ebetso ea thepa ea motheo e na le tšusumetso e kholo holim'a boleng ba ho roala, e leng se amang sekhahla sa sekhechana sa chip. Semicera's silicon carbide-coated base e eketsa katleho ea tlhahiso ea li-wafers tsa boleng bo holimo tsa LED mme e fokotsa ho kheloha ha leqhubu. Re boetse re fana ka likarolo tse ling tsa graphite bakeng sa li-reactor tsohle tsa MOCVD tse ntseng li sebelisoa hona joale. Re ka apesa hoo e batlang e le karolo efe kapa efe ka silicon carbide coating, le haeba bophara ba karolo e fihla ho 1.5M, re ntse re ka apara ka silicon carbide.

Tšimo ea Semiconductor, Ts'ebetso ea Phallo ea Oxidation, jj.

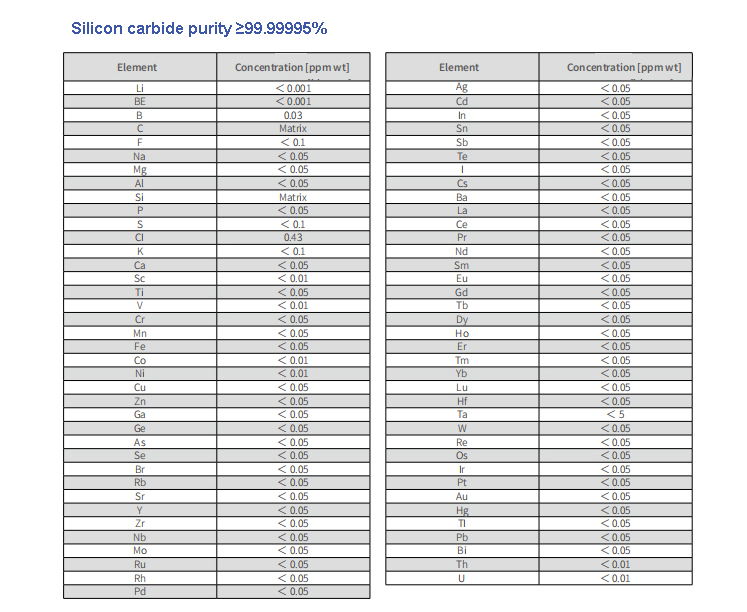

Ts'ebetsong ea semiconductor, ts'ebetso ea katoloso ea oxidation e hloka bohloeki bo phahameng ba sehlahisoa, 'me ho Semicera re fana ka litšebeletso tsa ho roala tloaelo le CVD bakeng sa boholo ba likarolo tsa silicon carbide.

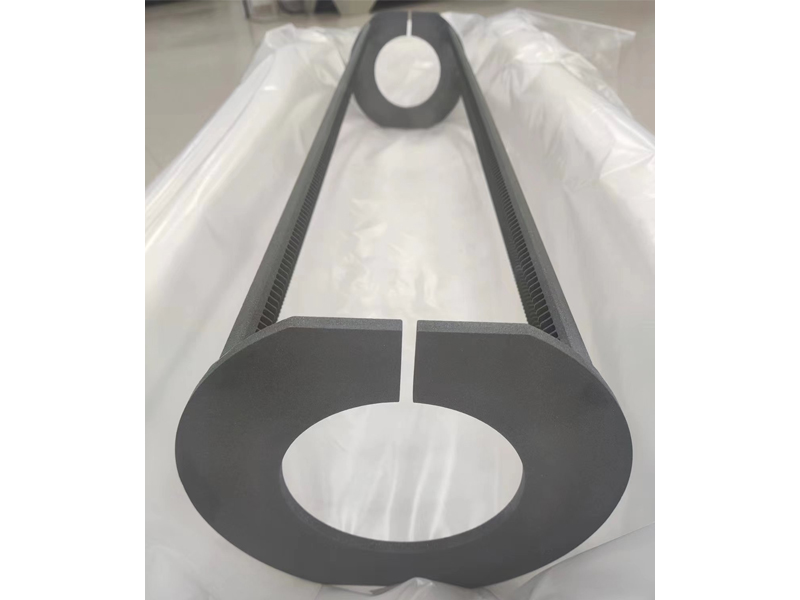

Setšoantšo se latelang se bontša silicon carbide slurry e entsoeng ka thata ea Semicea le tube ea silicon carbide sebōpi e hloekisitsoeng ka 100.0- boemoe hlokang lerolekamore. Basebetsi ba rona ba sebetsa pele ba roala. Bohloeki ba silicon carbide ea rona bo ka fihla ho 99.99%, 'me bohloeki ba ho roala sic bo feta 99.99995%..

Raw Silicon Carbide Paddle le SiC Process Tube in Cleaing

Silicon Carbide Wafer Boat CVD SiC Coated