Kenyelletso ea CVD TaC Coating:

CVD TaC Coating ke theknoloji e sebelisang mouoane oa lik'hemik'hale ho boloka tantalum carbide (TaC) e koahela holim'a substrate. Tantalum carbide ke thepa ea ceramic e sebetsang hantle e nang le thepa e ntle haholo ea mochini le lik'hemik'hale. Ts'ebetso ea CVD e hlahisa filimi e ts'oanang ea TaC holim'a substrate ka karabelo ea khase.

Lintlha tse ka sehloohong:

Excellent hardness le ho apara ho hanyetsa: Tantalum carbide e na le boima bo phahameng haholo, 'me Coating ea TaC ea CVD e ka ntlafatsa haholo ho hanyetsa ha substrate. Sena se etsa hore seaparo se be se loketseng bakeng sa lits'ebetso tse maemong a holimo, joalo ka lisebelisoa tsa ho itšeha le hlobo.

Botsitso bo Phahameng ba Mocheso: Liaparo tsa TaC li sireletsa sebōpi sa bohlokoa le likarolo tsa reactor mocheso ho fihlela ho 2200 ° C, ho bontša botsitso bo botle. E boloka botsitso ba lik'hemik'hale le mechine tlas'a maemo a feteletseng a mocheso, ho etsa hore e tšoanelehe bakeng sa ts'ebetso e phahameng ea mocheso le lisebelisoa libakeng tse phahameng tsa mocheso.

E babatsehang botsitso ba lik'hemik'hale: Tantalum carbide e na le khanyetso e matla ea kutu ho li-acids le li-alkali tse ngata, 'me CVD TaC Coating e ka thibela ka katleho tšenyo ea substrate libakeng tse senyang.

Boemo bo phahameng ba ho qhibiliha: Tantalum carbide e na le ntlha e phahameng ea ho qhibiliha (hoo e ka bang 3880 ° C), e lumellang CVD TaC Coating hore e sebelisoe maemong a phahameng a mocheso o feteletseng ntle le ho qhibiliha kapa ho senya.

E babatsehang mogote conductivity: Ho roala ha TaC ho na le conductivity e phahameng ea mocheso, e thusang ho senya mocheso ka katleho ka mekhoa e phahameng ea mocheso le ho thibela ho chesa ha libaka.

Lisebelisoa tse ka bang teng:

• Gallium Nitride (GaN) le Silicon Carbide epitaxial CVD reactor likarolo tse kenyeletsang li-wafer carrier, lijana tsa sathelaete, lishaoara, siling, le susceptors.

• Silicon carbide, gallium nitride le aluminium nitride (AlN) ea khōlo ea kristale e kenyeletsang li-crucibles, li-peed holders, lirings tse tataisang le li-filters.

• Likarolo tsa indasteri tse kenyelletsang lisebelisoa tsa ho futhumatsa tse hanyetsanang, li-nozzles tsa ente, mehele ea masking le li-jigs tsa brazing

Likarolo tsa ts'ebeliso:

• Mocheso o tsitsitseng ka holimo ho 2000 ° C, o lumella ho sebetsa ha mocheso o feteletseng

•E hanana le hydrogen (Hz), ammonia (NH3), monosilane (SiH4) le silicon (Si), e fana ka tšireletso libakeng tse thata tsa lik'hemik'hale.

• Thermal shock resistance e etsa hore ho be le lipotoloho tse sebetsang ka potlako

• Graphite e na le ho khomarela ka matla, ho netefatsa bophelo bo bolelele ba tšebeletso 'me ha ho na delamination ea ho roala.

• Bohloeki bo phahameng haholo ho felisa litšila tse sa hlokahaleng kapa litšila

• Ho koaheloa ka mokhoa o hlophisitsoeng ho mamella maemo a thata

Litlhaloso tsa tekheniki:

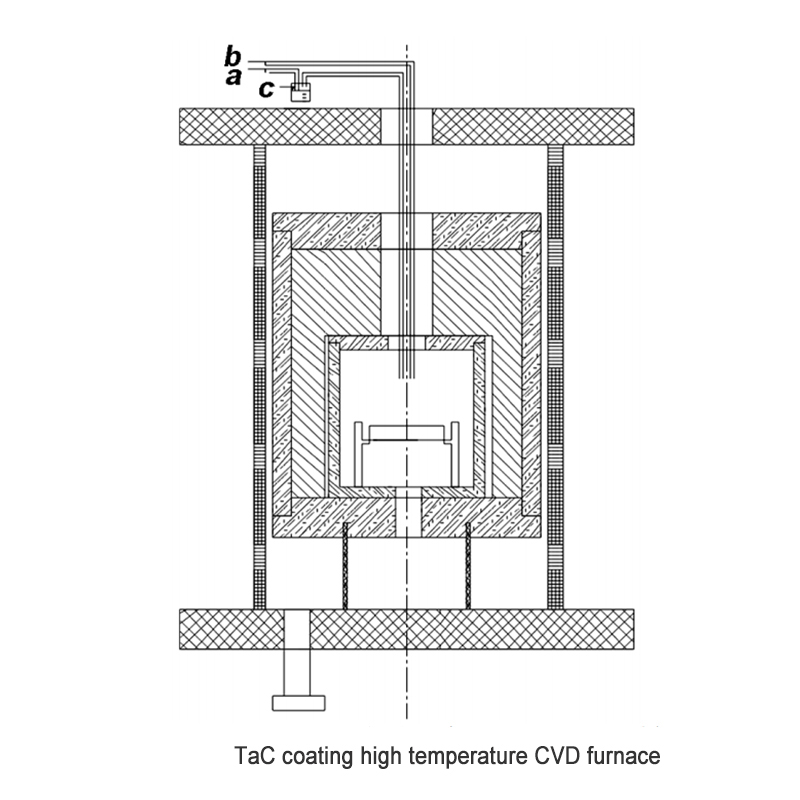

Ho lokisoa ha liaparo tse teteaneng tsa tantalum carbide ka CVD:

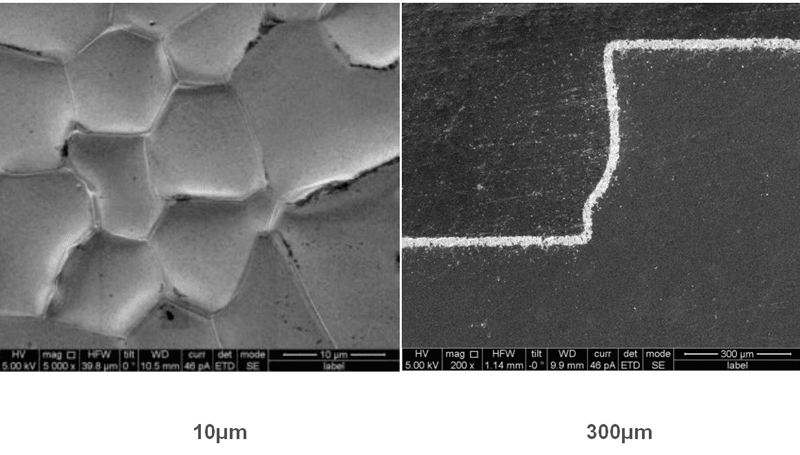

TAC e koahetsoeng ka kristale e phahameng le ho tšoana ho babatsehang:

CVD TAC COATING Technical Parameters_Semicera:

| Thepa ea 'mele ea ho roala ha TaC | |

| Botenya | 14.3 (g/cm³) |

| Bongata ba Concentration | 8x1015/cm |

| Essivity e khethehileng | 0.3 |

| Coefficient ea ho eketsa mocheso | 6.3 10-6/K |

| Ho thatafala(HK) | 2000 HK |

| Bongata ba Resistivity | 4.5 ohm-cm |

| Khanyetso | 1x10-5Ohm*cm |

| Ho tsitsa ha mocheso | <2500℃ |

| Motsamao | 237 cm2/Vs |

| Boholo ba graphite bo fetoha | -10 ~ 20um |

| Botenya ba ho roala | ≥20um boleng bo tloaelehileng (35um+10um) |

Tse ka holimo ke litekanyetso tse tloaelehileng.