Ts'ebetso ea MEMS - Bonding: Kopo le Ts'ebetso ho Indasteri ea Semiconductor, Ts'ebeletso e Ikemetseng ea Semicera

Liindastering tsa microelectronics le semiconductor, theknoloji ea MEMS (micro-electromechanical systems) e fetohile e 'ngoe ea mekhoa ea mantlha e tsamaisang mekhoa e mecha le lisebelisoa tse sebetsang hantle. Ka tsoelopele ea mahlale le thekenoloji, theknoloji ea MEMS e 'nile ea sebelisoa haholo ho li-sensor, li-actuator, lisebelisoa tsa mahlo, lisebelisoa tsa bongaka, lisebelisoa tsa motlakase tsa likoloi le likarolo tse ling,' me butle-butle e fetohile karolo ea bohlokoa ea theknoloji ea morao-rao. Libakeng tsena, mokhoa oa ho kopanya (Bonding), e le mohato o ka sehloohong oa ts'ebetso ea MEMS, o phetha karolo ea bohlokoa ts'ebetsong le ho tšepahala ha sesebelisoa.

Bonding ke theknoloji e kopanyang ka tieo lisebelisoa tse peli kapa ho feta ka mekhoa ea 'mele kapa ea lik'hemik'hale. Hangata, likarolo tse fapaneng tsa lisebelisoa li hloka ho hokahana ka ho tlamahanngoa lisebelisoa tsa MEMS ho fihlela bots'epehi ba sebopeho le ts'ebetso ea ts'ebetso. Ts'ebetsong ea ho etsa lisebelisoa tsa MEMS, ho tlamahane hase feela mokhoa oa ho hokahanya, empa hape ho ama ka ho toba botsitso ba mocheso, matla a mochine, ts'ebetso ea motlakase le likarolo tse ling tsa sesebelisoa.

Ts'ebetsong ea MEMS e nepahetseng haholo, theknoloji ea bonding e hloka ho netefatsa kamano e haufi pakeng tsa lisebelisoa ha ho ntse ho qoba liphoso tse amang ts'ebetso ea sesebelisoa. Ka hona, taolo e nepahetseng ea ts'ebetso ea ho kopanya le lisebelisoa tsa boleng bo holimo ke lintlha tsa bohlokoa ho netefatsa hore sehlahisoa sa ho qetela se kopana le litekanyetso tsa indasteri.

Likopo tsa bonding tsa MEMS indastering ea semiconductor

Indastering ea semiconductor, theknoloji ea MEMS e sebelisoa haholo ho hlahiseng lisebelisoa tse nyane tse kang li-sensor, li-accelerometer, li-sensor tsa khatello le li-gyroscopes. Ka tlhokahalo e ntseng e eketseha ea lihlahisoa tse nyenyane, tse kopantsoeng le tse bohlale, litlhoko tsa ho nepahala le ts'ebetso ea lisebelisoa tsa MEMS le tsona lia eketseha. Lits'ebetsong tsena, theknoloji ea ho kopanya e sebelisoa ho hokahanya lisebelisoa tse fapaneng tse kang li-wafers tsa silicon, likhalase, tšepe le li-polymers ho finyella mesebetsi e sebetsang hantle le e tsitsitseng.

1. Li-sensor tsa khatello le li-accelerometers

Libakeng tsa likoloi, sefofane, lisebelisoa tsa elektronike tsa bareki, joalo-joalo, li-sensor tsa khatello ea MEMS le li-accelerometer li sebelisoa haholo mekhoeng ea ho lekanya le ho laola. Mokhoa oa ho kopanya o sebelisetsoa ho hokahanya li-chips tsa silicon le likarolo tsa sensor ho netefatsa kutloisiso e phahameng le ho nepahala. Li-sensor tsena li tlameha ho khona ho mamella maemo a feteletseng a tikoloho, mme lits'ebetso tsa boleng bo holimo tsa tlamahano li ka thibela ka katleho thepa hore e se ke ea thijoa kapa e se sebetse ka lebaka la liphetoho tsa mocheso.

2. Lisebelisoa tsa Micro-optical le li-switch tsa MEMS tsa optical

Sebakeng sa puisano ea optical le lisebelisoa tsa laser, lisebelisoa tsa optical tsa MEMS le li-switch optical li phetha karolo ea bohlokoa. Theknoloji ea bonding e sebelisetsoa ho finyella kamano e nepahetseng pakeng tsa lisebelisoa tsa MEMS tse thehiloeng ka silicon le lisebelisoa tse kang optical fibers le liipone ho netefatsa katleho le botsitso ba phetisetso ea optical signal. Haholo-holo lits'ebetsong tse nang le maqhubu a phahameng, bandwidth e pharaletseng le phetisetso ea sebaka se selelele, theknoloji e sebetsang hantle ea bonding e bohlokoa.

3. Li-gyroscope tsa MEMS le li-sensor tsa inertial

Li-gyroscope tsa MEMS le li-sensor tsa inertial li sebelisoa haholo bakeng sa ho tsamaea hantle le ho beha maemo liindastering tse phahameng tse kang ho khanna ka boithaopo, liroboto le sefofane. Mekhoa e phahameng ea ho kopanya e ka netefatsa ho tšepahala ha lisebelisoa le ho qoba ho senyeha ha ts'ebetso kapa ho hlōleha nakong ea ts'ebetso ea nako e telele kapa ts'ebetso e phahameng ea maqhubu.

Litlhoko tsa bohlokoa tsa ts'ebetso ea thekenoloji ea bonding ts'ebetsong ea MEMS

Ts'ebetsong ea MEMS, boleng ba ts'ebetso ea ho kopanya ka ho toba bo lekanya ts'ebetso, bophelo le botsitso ba sesebelisoa. Bakeng sa ho netefatsa hore lisebelisoa tsa MEMS li ka sebetsa ka ts'epo nako e telele maemong a fapaneng a ts'ebeliso, theknoloji ea bonding e tlameha ho ba le ts'ebetso e latelang ea bohlokoa:

1. Botsitso bo phahameng ba mocheso

Libaka tse ngata tsa kopo indastering ea semiconductor li na le maemo a phahameng a mocheso, haholo-holo masimong a likoloi, sebaka sa sefofane, joalo-joalo.

2. Ho hanyetsa ho apara ho phahameng

Lisebelisoa tsa MEMS hangata li kenyelletsa meaho e menyenyane, 'me likhohlano tsa nako e telele le ho sisinyeha ho ka baka ho senyeha ha likarolo tsa khokahano. Thepa ea tlamahano e hloka ho ba le khanyetso e ntle ea ho apara ho netefatsa botsitso le katleho ea sesebelisoa ka tšebeliso ea nako e telele.

3. Bohloeki bo phahameng

Indasteri ea semiconductor e na le litlhoko tse thata haholo mabapi le bohloeki ba lintho tse bonahalang. Tšilafalo efe kapa efe e nyane e ka baka ho hloleha ha sesebelisoa kapa ho senyeha ha ts'ebetso. Ka hona, lisebelisoa tse sebelisoang ts'ebetsong ea ho kopanya li tlameha ho ba le bohloeki bo phahameng ka ho fetisisa ho netefatsa hore sesebelisoa ha se amehe ke tšilafalo ea ka ntle nakong ea ts'ebetso.

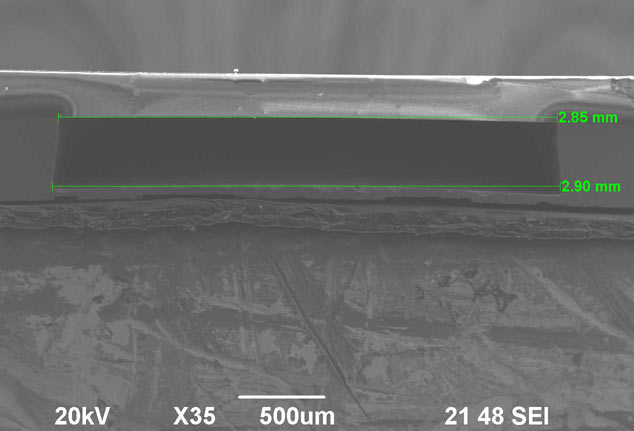

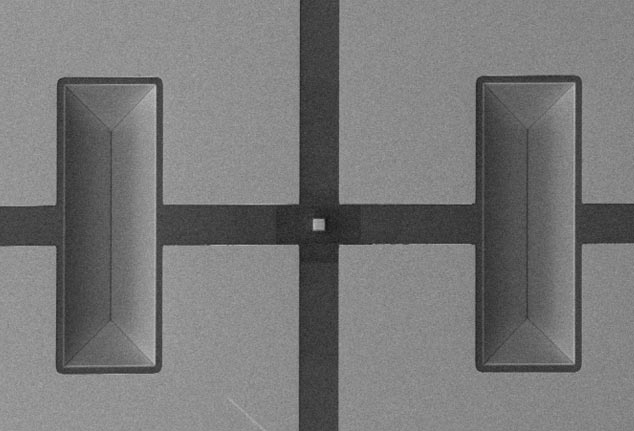

4. Ho nepahala ha tlamahano e nepahetseng

Lisebelisoa tsa MEMS hangata li hloka ho nepahala ha boemo ba micron kapa esita le boemo ba nanometer. Mokhoa oa ho kopanya o tlameha ho etsa bonnete ba hore ho na le docking e nepahetseng ea lera le leng le le leng la lisebelisoa ho netefatsa hore ts'ebetso le ts'ebetso ea sesebelisoa ha li amehe.

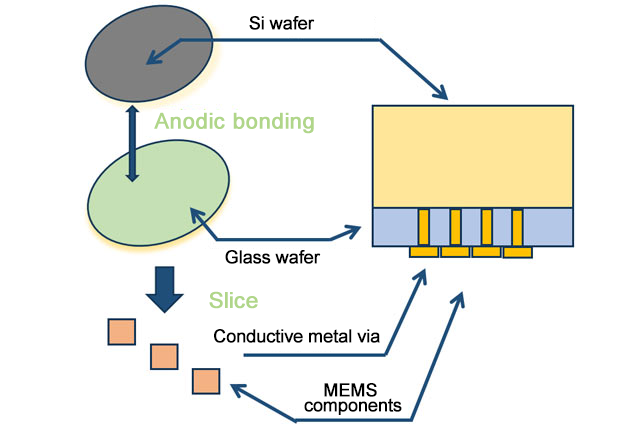

Ho kopana ha anodic

Anodic bonding:

● E sebetsa pakeng tsa maqhama a silicon le khalase, tšepe le khalase, semiconductor le alloy, le semiconductor le khalase.

Khokahano ea Eutectoid:

● E sebetsa ho lisebelisoa tse kang PbSn, AuSn, CuSn, le AuSi

Ho kopanya sekhomaretsi:

● Sebelisa sekhomaretsi se khethehileng sa ho kopanya, se loketseng li-glues tse khethehileng tsa ho kopanya tse kang AZ4620 le SU8

● E sebetsa ho 4-inch le 6-inch

Semicera Custom Bonding Service

Joaloka mofani ea etellang pele indastering ea litharollo tsa ts'ebetso ea MEMS, Semicera e ikemiselitse ho fa bareki lits'ebeletso tsa bonding tse nepahetseng ka ho fetesisa, tse nang le botsitso bo phahameng. Theknoloji ea rona ea ho kopanya e ka sebelisoa ka ho pharaletseng mabapi le ho hokahanya ha lisebelisoa tse fapaneng, ho kenyelletsa le silicon, khalase, tšepe, li-ceramics, joalo-joalo, ho fana ka litharollo tse ncha bakeng sa likopo tse phahameng ka ho fetisisa masimong a semiconductor le MEMS.

Semicera e na le lisebelisoa tse tsoetseng pele tsa tlhahiso le lihlopha tsa tekheniki, 'me e ka fana ka litharollo tsa bonding tse ikhethileng ho latela litlhoko tse ikhethang tsa bareki. Ebang ke khokahano e ka tšeptjoang tlas'a mocheso o phahameng le tikoloho ea khatello e phahameng, kapa bonding e nepahetseng ea lisebelisoa tse nyenyane, Semicera e ka finyella litlhoko tse fapaneng tse rarahaneng tsa ts'ebetso ho netefatsa hore sehlahisoa ka seng se ka finyella litekanyetso tse phahameng ka ho fetisisa tsa boleng.

Tšebeletso ea rona e tloaelehileng ea ho kopanya ha e felle feela mekhoeng e tloaelehileng ea ho kopanya, empa e boetse e kenyelletsa ho kopanya tšepe, ho kopanya mocheso oa mocheso, ho kopanya sekhomaretsi le mekhoa e meng, e ka fanang ka ts'ehetso ea litsebi tsa setsebi bakeng sa lisebelisoa tse fapaneng, mehaho le litlhoko tsa kopo. Ntle le moo, Semicera e ka boela ea fa bareki tšebeletso e felletseng ho tloha ho nts'etsopele ea prototype ho isa tlhahiso e kholo ho netefatsa hore tlhoko e 'ngoe le e' ngoe ea tekheniki ea bareki e ka phethahala ka nepo.