Zirconia ke thepa e nang le matla a phahameng a mochine le ho robeha ho thata ka mocheso oa kamore.Zirconia ea rona (ZrO2) e kenyelelitsoe ka 3mol% Y2O3 zirconia e tsitsitseng e tsitsitseng (PSZ).Hobane bophara ba karoloana ea thepa ea PSZ e nyane, e ka sebetsoa ka nepo e phahameng, mme ts'ebeliso ea eona likarolong tse nepahetseng tsa machining joalo ka hlobo e ntse e hola.Ntle le moo, e ka sebelisoa bakeng sa lisebelisoa tsa indasteri, likarolo tsa sehokelo sa optical le lisebelisoa tse silakanyang.The high fracture toughness of PSZ e ka sebelisoa ho etsa liliba tse khethehileng, hape e sebelisoa haholo ka lithipa tsa ceramic tsa malapeng, slicer le likarolo tse ling.

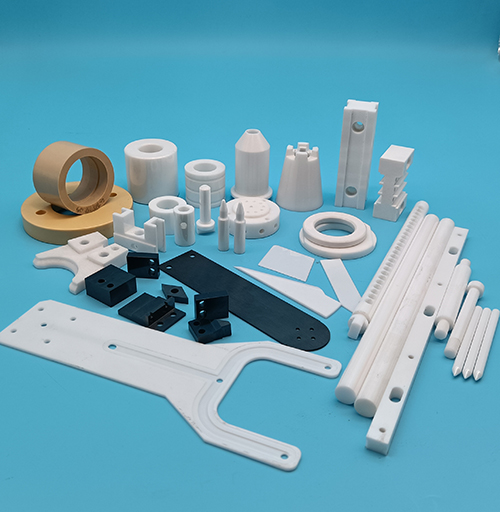

Zirconia (ZrO2) Ke sebelisa haholo

Lisebelisoa tsa hlobo le hlobo (liforomo tse fapa-fapaneng, mokhoa o nepahetseng oa ho beha maemo, ho kenya letsoho);Likarolo tsa Mill (classifier, leloala la phallo ea moea, leloala la lifaha);Sesebelisoa sa indasteri (seha sa indasteri, mochini oa slitter, moqolo oa khatiso o bataletseng);Likarolo tsa sehokelo sa Optical (ring ea ho tiisa, sleeve, sebopeho sa V-groove);Selemo se khethehileng (coil spring, plate spring);Lihlahisoa tsa bareki (screwdriver tse nyane tse insulated, thipa ea ceramic, slicer).

Thepa ea Lintho

| Ntho | 95% Alumina | 99% Alumina | Zirconia | Silicon carbide | SiliconeNitride | AluminiumNitride | Ceramic e sebetsang |

| Mmala | tšoeu | Bosehla bo kganyang | tšoeu | ntsho | ntsho | bohlooho | tšoeu |

| Boima ba 'mele (g/cm3) | 3.7g/cm3 | 3.9g/cm3 | 6.02g/cm3 | 3.2g/cm3 | 3.25g/cm3 | 3.2g/cm3 | 2.48g/cm3 |

| Ho Monyeha ha Metsi | 0% | 0% | 0% | 0% | 0% | 0% | 0% |

| Ho thatafala(HV) | 23.7 | 23.7 | 16.5 | 33 | 20 | - | - |

| Flexural Strength(MPa) | 300MPa | 400MPa | 1100MPa | 450MPa | 800MPa | 310MPa | 91MPa |

| Compressive Strength(MPa) | 2500MPa | 2800MPa | 3600MPa | 2000MPa | 2600MPa | - | 340MPa |

| Modulus ea Mocha oa Elasticity | 300GPa | 300GPa | 320GPa | 450GPa | 290GPa | 310 ~ 350GPa | 65GPa |

| Karolelano ea Poisson | 0.23 | 0.23 | 0.25 | 0.14 | 0.24 | 0.24 | 0.29 |

| Thermal Conductivity | 20W/m°C | 32W/m°C | 3W/m°C | 50W/m°C | 25W/m°C | 150W/m°C | 1.46W/m°C |

| Matla a Dielectric | 14KV/mm | 14KV/mm | 14KV/mm | 14KV/mm | 14KV/mm | 14KV/mm | 14KV/mm |

| Ho hanyetsa Bophahamo (25℃) | >1014Ω·cm | >1014Ω·cm | >1014Ω·cm | >105Ω·cm | >1014Ω·cm | >1014Ω·cm | >1014Ω·cm |