Semicerae fana ka motlotloGa2O3Epitaxy, tharollo ea morao-rao e etselitsoeng ho sutumelletsa meeli ea matla a elektronike le optoelectronics. Theknoloji ena e tsoetseng pele ea epitaxial e sebelisa thepa e ikhethang ea Gallium Oxide (Ga2O3) ho fana ka ts'ebetso e phahameng ho likopo tse batlang.

Likarolo tsa Bohlokoa:

• Ikhethang Wide Bandgap: Ga2O3Epitaxye na le bandgap e pharalletseng haholo, e lumellang hore ho be le li-voltage tse phahameng haholo le ts'ebetso e sebetsang libakeng tse matla a phahameng.

•High Thermal Conductivity: Lera la epitaxial le fana ka conductivity e babatsehang ea mocheso, ho netefatsa ts'ebetso e tsitsitseng esita le tlas'a maemo a phahameng a mocheso, e leng se etsang hore e be se loketseng bakeng sa lisebelisoa tse phahameng tsa maqhubu.

•Boleng bo Phahameng ba Lintho: Finyella boleng bo phahameng ba kristale bo nang le mefokolo e fokolang, ho netefatsa ts'ebetso e nepahetseng ea sesebelisoa le bophelo bo bolelele, haholo lits'ebetsong tse bohlokoa joalo ka li-transistors tsa matla le li-detectors tsa UV.

•Mefuta-futa ea Likopo: E loketse ka ho feletseng bakeng sa lisebelisoa tsa elektronike tsa matla, lisebelisoa tsa RF, le optoelectronics, e fanang ka motheo o tšepahalang oa lisebelisoa tsa semiconductor tsa moloko o latelang.

Sibolla bokhoni baGa2O3Epitaxyka litharollo tse ncha tsa Semicera. Lihlahisoa tsa rona tsa epitaxial li etselitsoe ho finyella litekanyetso tse phahameng ka ho fetisisa tsa boleng le ts'ebetso, e leng ho nolofalletsang lisebelisoa tsa hau ho sebetsa ka katleho e kholo le ho tšepahala. Khetha Semicera bakeng sa theknoloji ea semiconductor e tsoetseng pele.

| Lintho | Tlhahiso | Patlisiso | Dummy |

| Crystal Parameters | |||

| Polytype | 4H | ||

| Phoso ea sebopeho sa bokaholimo | <11-20>4±0.15° | ||

| Litekanyetso tsa Motlakase | |||

| Dopant | n-mofuta oa Nitrojene | ||

| Ho hanyetsa | 0.015-0.025ohm · cm | ||

| Mechanical Parameters | |||

| Diameter | 150.0±0.2mm | ||

| Botenya | 350±25 μm | ||

| Boemo ba mantlha bo bataletseng | [1-100]±5° | ||

| Bolelele ba pele bo bataletseng | 47.5±1.5mm | ||

| Folete ea bobeli | Ha ho letho | ||

| TTV | ≤5 μm | ≤10 μm | ≤15 μm |

| LTV | ≤3 μm(5mm*5mm) | ≤5 μm(5mm*5mm) | ≤10 μm(5mm*5mm) |

| Inamela | -15μm ~ 15μm | -35μm ~ 35μm | -45μm ~ 45μm |

| Warp | ≤35 μm | ≤45 μm | ≤55 μm |

| Front(Si-face) roughness(AFM) | Ra≤0.2nm (5μm*5μm) | ||

| Sebopeho | |||

| Boima ba micropipe | <1 e/cm2 | <10 e/cm2 | <15 e/cm2 |

| Litšila tsa tšepe | ≤5E10atoms/cm2 | NA | |

| BPD | ≤1500 ea/cm2 | ≤3000 ea/cm2 | NA |

| TSD | ≤500 ea/cm2 | ≤1000 ea/cm2 | NA |

| Boleng ba Pele | |||

| Pele | Si | ||

| Qetello ea bokaholimo | Si-face CMP | ||

| Likaroloana | ≤60ea/wafer (boholo ≥0.3μm) | NA | |

| Mengwapo | ≤5ea/mm. Bolelele ba kakaretso ≤Diameter | Bolelele bo akaretsang≤2*Diameter | NA |

| Lekhapetla la lamunu/makoti/matheba/maphatso/mapetso/tshilafatso | Ha ho letho | NA | |

| Li-edge chips/indents/fracture/hex plates | Ha ho letho | ||

| Libaka tsa polytype | Ha ho letho | Kakaretso≤20% | Kakaretso≤30% |

| Ho tšoaea ka laser ka pele | Ha ho letho | ||

| Boleng ba Morao | |||

| Qetello ea morao | C-sefahleho sa CMP | ||

| Mengwapo | ≤5ea/mm, bolelele bo akaretsang≤2* bophara | NA | |

| Litšitiso tse ka morao (li-chips / indents) | Ha ho letho | ||

| Bokhopo ba mokokotlo | Ra≤0.2nm (5μm*5μm) | ||

| Ho tšoaea ka morao laser | 1 mm (ho tloha pheletsong e ka holimo) | ||

| Qetello | |||

| Qetello | Chamfer | ||

| Sephutheloana | |||

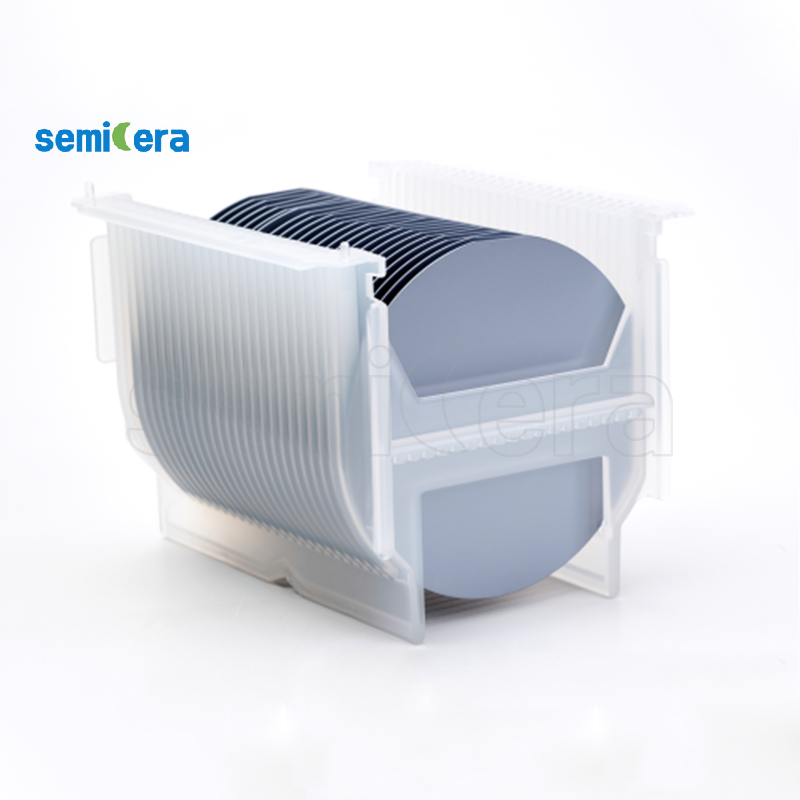

| Sephutheloana | Epi e loketse ho paka ka vacuum Sephutheloana sa lik'hasete tse nang le liphaephe tse ngata | ||

| *Lintlha: "NA" e bolela hore ha ho na kopo Lintho tse sa boleloang li ka lebisa ho SEMI-STD. | |||