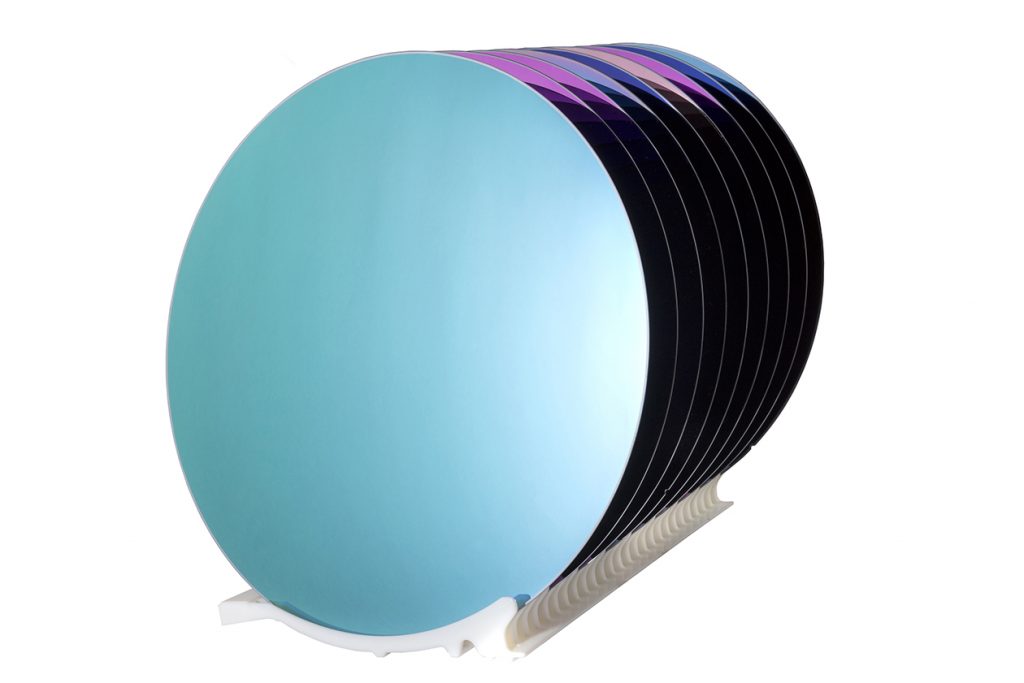

Semiconductorliphaphatha tsa silicon carbide (SiC)., thepa ena e ncha e hlahile butle-butle lilemong tsa morao tjena, ka thepa ea eona e ikhethang ea 'mele le ea lik'hemik'hale, e kentse matla a macha bakeng sa indasteri ea semiconductor.Li-wafers tsa SiC, ho sebelisa li-monocrystals e le lisebelisoa tse tala, li hōlileng ka hloko ke lik'hemik'hale tsa mouoane oa lik'hemik'hale (CVD), 'me ponahalo ea tsona e fana ka menyetla ea ho etsa mocheso o phahameng, maqhubu a phahameng le lisebelisoa tsa elektronike tse matla.

Lefapheng la matla a elektroniki,Li-wafers tsa SiCli sebelisoa ha ho etsoa li-converter tse sebetsang hantle haholo, li-charger, lisebelisoa tsa motlakase le lihlahisoa tse ling. Lefapheng la puisano, e sebelisetsoa ho etsa lisebelisoa tsa RF tsa maqhubu a phahameng le a lebelo le phahameng le lisebelisoa tsa optoelectronic, ho beha lejoe la sekhutlo le tiileng la tsela e kholo ea mehla ea tlhahisoleseding. Lefapheng la lisebelisoa tsa elektroniki tsa likoloi,Li-wafers tsa SiCtheha lisebelisoa tsa motlakase tsa likoloi tse matla haholo, tse tšepahalang haholo ho felehetsa polokeho ea mokhanni oa ho khanna.

Ka tsoelo-pele e tsoelang pele ea theknoloji, theknoloji ea tlhahiso eaLi-wafers tsa SiCe ntse e hōla le ho feta, 'me theko e ntse e fokotseha butle-butle. Sesebediswa sena se secha se bonts'a bokhoni bo boholo ba ho ntlafatsa ts'ebetso ea sesebelisoa, ho fokotsa tšebeliso ea matla, le ho ntlafatsa tlholisano ea lihlahisoa. Ke shebile pele,Li-wafers tsa SiCe tla bapala karolo ea bohlokoa ho indasteri ea semiconductor, ho tlisa boiketlo bo eketsehileng le polokeho bophelong ba rona.

A re lebelleng ka thabo ho naleli ena e khanyang ea semiconductor - SiC wafer, bakeng sa bokamoso ba tsoelo-pele ea saense le theknoloji ho hlalosa khaolo e khanyang haholoanyane.

Nako ea poso: Nov-27-2023