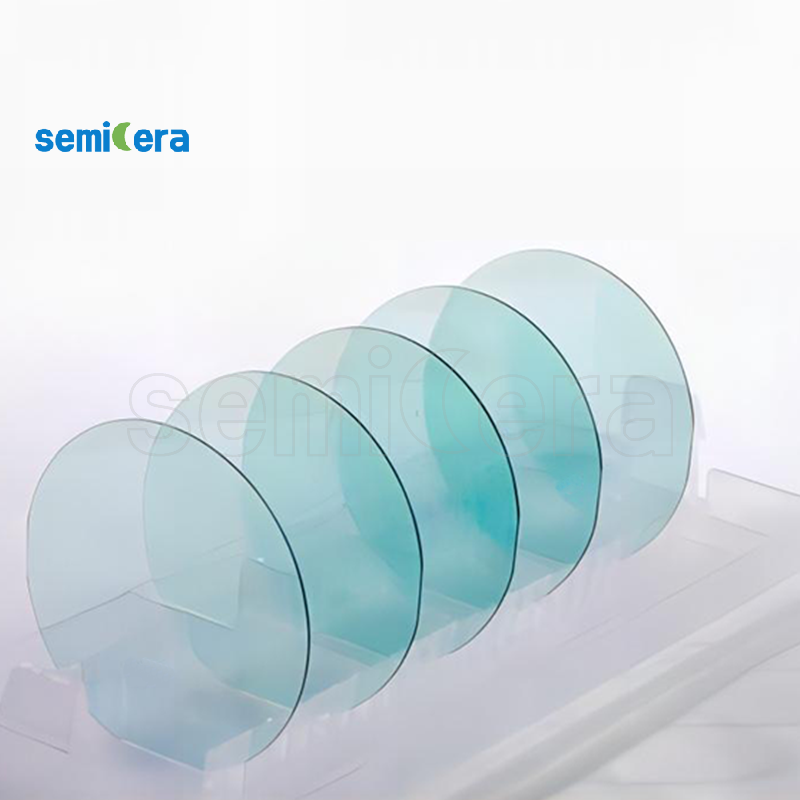

Lisosa tsa SemiceraLi-paddles tsa SiCli entsoe bakeng sa katoloso e fokolang ea mocheso, ho fana ka botsitso le ho nepahala lits'ebetsong moo ho nepahala ha dimensional ho leng bohlokoa. Sena se etsa hore e be tse loketseng bakeng sa lits'ebetso mooliphaphathali kenngoa ka makhetlo a mangata a ho futhumatsa le ho pholile, kaha seketsoana sa wafer se boloka botšepehi ba sona, ho netefatsa ts'ebetso e tsitsitseng.

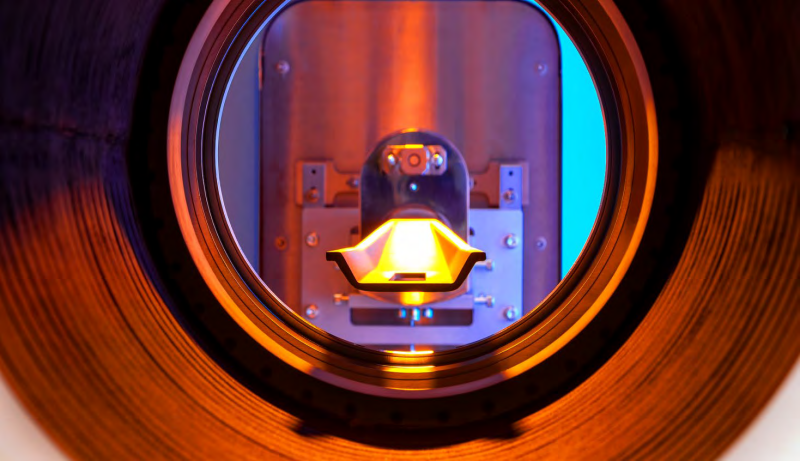

Ho kenyelletsa Semicera'ssilicon carbide diffusion paddlesmoleng oa hau oa tlhahiso e tla ntlafatsa ts'epo ea ts'ebetso ea hau, ka lebaka la thepa ea bona e phahameng ea mocheso le lik'hemik'hale. Li-paddles tsena li nepahetse bakeng sa ts'ebetso ea phallo, oxidation le annealing, ho netefatsa hore li-wafers li tšoaroa ka hloko le ka nepo mohatong o mong le o mong.

Boqapi bo bohareng ba Semicera'sSekoahelo sa SiCmoralo. Li-paddles tsena li etselitsoe hore li lekane hantle ka har'a lisebelisoa tse teng tsa semiconductor, li fana ka ts'ebetso e ntlafalitsoeng ea ho sebetsana le eona. Sebopeho se bobebe le moralo oa ergonomic ha o ntlafatse feela lipalangoang tsa liphaephe empa hape o fokotsa nako ea ts'ebetso, e bakang tlhahiso e ntlafalitsoeng.

| Thepa ea 'mele ea Recrystallized Silicon Carbide | |

| Thepa | Boleng bo Tlwaelehileng |

| Mocheso oa ho sebetsa (°C) | 1600°C (ka oksijene), 1700°C (ho fokotsa tikoloho) |

| Likahare tsa SiC | 99.96% |

| Free Si content | <0.1% |

| Boima ba bongata | 2.60-2.70 g/cm3 |

| porosity e bonahalang | <16% |

| Matla a ho hatella | > 600 MPa |

| Matla a ho kobeha a batang | 80-90 MPa (20°C) |

| Matla a ho kobeha a chesang | 90-100 MPa (1400°C) |

| Katoloso ea mocheso @1500°C | 4.70 10-6/°C |

| Thermal conductivity @1200°C | 23 W/m•K |

| Modulase oa elastic | 240 GPA |

| Ho hanyetsa mocheso oa mocheso | E ntle haholo |